|

|

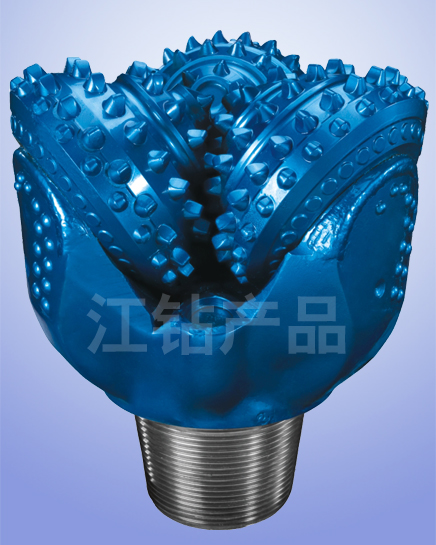

Roller cone bits for

|

|

|

|

MD high speed motor bit

Horizontal well drilling technology is improved continuously, in which extended reach well drilling technology and multilateral well drilling technology have been developed rapidly. Kingdream follows improvement of drilling technology tightly, and has developed new type of MD high speed motor bit suitable for directional well and horizontal well success fully. Work of bit in directional well and horizontal well has been changed greatly compare with which in straight well, new type of MD high speed motor bit has the advantages of applying for high rotary speed, strong gage protection ability and stability, high reliability, well hydraulic effect and long service life. fully. Work of bit in directional well and horizontal well has been changed greatly compare with which in straight well, new type of MD high speed motor bit has the advantages of applying for high rotary speed, strong gage protection ability and stability, high reliability, well hydraulic effect and long service life.

MD high speed motor bit is suitable for drilling with rotary speed from 300 to 90 RPM, which is the ideal choice for directional well, horizontal well and horizontal multilateral well drilling. |

|

|

|

|

|

|

MINI-MD cone bit for slim hole drilling applications

Increase of drilling speed in slim hole section of lower part of deep well and super-deep well is very difficult, MiniMD cone bit for slim holes has improved service life and security of bit, and decreased round trip times, therefore, realized the purpose of increasing drilling speed and decreasing drilling cost. MiniMD cone bit for slim holes is with the  feature of MD high speed motor bit, and designed with special bearing seal structure and oil storage system, tooth material, cutting structure and formation lithology are matched reasonably to solve the problems of low efficiency and tooth break & fall while drilling in complex formations. feature of MD high speed motor bit, and designed with special bearing seal structure and oil storage system, tooth material, cutting structure and formation lithology are matched reasonably to solve the problems of low efficiency and tooth break & fall while drilling in complex formations.

MiniMD cone bit for slim holes is the ideal choice for slim-hole section drilling in deep well and super-deep well. |

|

|

|

|

SUPER-MD super-high speed motor bit

Turbine drilling tools are used widely in Russia oilfield, bits run with super high speed, rotary speed of turbine which is matched with 11 5/8 and 81/ 2 bits reaches to 400rpm ~600rpm, therefore, service life of normal cone bits is about 10 hours usually. Kingdream has invented roller-journal compound bearing for working situation with super high rotary speed, which matches with metal seal, in order to provide bit with high bearing reliability and long life  in situation of super high rotary speed. Kingdream has also developed cutting structure and extended double nozzle hydraulic structure to be suitable for drilling with super high rotary speed. SMD super-high speed motor bit matches with turbine while be used in Russia market, the stable service life of bit can reaches to more than 30 hours in the work situation of above 400 RPM. in situation of super high rotary speed. Kingdream has also developed cutting structure and extended double nozzle hydraulic structure to be suitable for drilling with super high rotary speed. SMD super-high speed motor bit matches with turbine while be used in Russia market, the stable service life of bit can reaches to more than 30 hours in the work situation of above 400 RPM.

SMD super-high speed motor bit is recommended to work in high rotary speed from 250rpm to 600rpm, which is quite economical. |

|

|

|

|

HF bit for hard formations

Petroleum exploration has been developed to deep formations gradually, in deep formations (compact plastic mudstone, lava and granite etc.,), low ROP restrict the economic of development in deep well or super-deep well. Failure types, such as tooth break, tooth wear, cone tip wear and bit diameter shrink etc., usually appear when conventional cone bits drill in hard formations. So we have developed HF series bit for hard formations through analyze and research these failure types deeply and make use of advanced computer 3D simulation technology and lots of platform experiments. cone bits drill in hard formations. So we have developed HF series bit for hard formations through analyze and research these failure types deeply and make use of advanced computer 3D simulation technology and lots of platform experiments.

Result in site shows HF series bit has the advantages of long service life, high reliability, fast ROP and strong gage protection ability etc.. HF series bit is the ideal choice for drilling in hard formations and strong abrasive formations effectively and safely. |

|

|

|

|

SWT steel tooth bit with high efficiency

Wear resistance of teeth of conventional steel tooth cone bit is not good, tooth shape structure is lack of optimization, which leads to decrease of average ROP. SWT series steel tooth bit with high efficiency can solve these problems, with strong  wear resistant teeth and fast ROP, bit can work more stably, which is more suitable for drilling in soft or middle soft formations with high rotary speed. wear resistant teeth and fast ROP, bit can work more stably, which is more suitable for drilling in soft or middle soft formations with high rotary speed.

Application of SWT series steel tooth bit with high efficiency is the best way to solve the problem of increasing drilling speed in higher part of well. |

|

|

|

|

|

A series bit for air drilling

In hard formation with less water content, formations with serious leakage or with low pressure, in order to achieve higher drilling speed, air drilling process is usually adopted. Problems such as short service life, low ROP, weak gage protection  ability etc. appear frequently for conventional cone bit in air drilling conditions. Aim at air drilling condition, Kingdream has developed A series bit for air drilling which can solve these problems. ability etc. appear frequently for conventional cone bit in air drilling conditions. Aim at air drilling condition, Kingdream has developed A series bit for air drilling which can solve these problems. |

|

|

|

HJ metal sealed bit with journal bearing

HJ series bit adopts metal seal with journal bearing, which can drill stably with high rotary speed, it’s the ideal tool for drilling directional  well and horizontal well. Compared with conventional rubber sealed bit, its service life can be increased by 35% with same drilling parameters. well and horizontal well. Compared with conventional rubber sealed bit, its service life can be increased by 35% with same drilling parameters. |

|

|

|

|

GJ metal sealed bit with roller bearing

GJ series bit adopts metal seal with roller bearing, which can drill stably with middle to low WOB and middle to high RPM, it’s the ideal choice for higher part of well section. Insert bit can adopt carbide compacts with high efficiency such as offset  crested scoop chisel compact, scoop chisel compact, wedge compact and conical compact etc.. Increase thickness of hardfacing layer and exposure height of tooth for steel tooth bit. crested scoop chisel compact, scoop chisel compact, wedge compact and conical compact etc.. Increase thickness of hardfacing layer and exposure height of tooth for steel tooth bit.

This kind of series bit has several optional features, which can enhance the ability of applying for different drilling process and various complex formations. |

|

|

|

|

HA rubber sealed bit with journal bearing

HA series bit adopts rubber seal with journal bearing, which can sustain higher WOB under normal rotary speed and is suitable for drilling  in formations from very soft to middle hard by properly selecting different cutting structure. in formations from very soft to middle hard by properly selecting different cutting structure. |

|

|

|

|

|

GA rubber sealed bit with roller bearing

GA series bit adopts rubber seal with roller bearing, which is the ideal and economical tool for drilling applications where middle to low WOB and high RPM are required. WOB and high RPM are required. |

|

|

|

|

YC Series single cone bit

Diamond enhanced carbide inserts are arranged on top of the cone of YC single cone bit to improve wear resistance for longer working life of the bit. New type of hydraulic system enhances cone and bottom hole cleaning ability to assure higher  ROP of the bit. Large diameter active cutting conical-spherical inserts are used for gage protection on bit body, so that the bit has excellent gage holding and up-reaming abilities. ROP of the bit. Large diameter active cutting conical-spherical inserts are used for gage protection on bit body, so that the bit has excellent gage holding and up-reaming abilities.

This series of bit is suitable for slim hole drilling operations such as reentry and sidetracking operations. |

|

|

|

|

|

SKF series floating bearing O-ring seal tri-cone bit

SKF series bit is a kind of high efficiency bit for vertical and directional drilling applications, especially suitable for these kinds of drilling applications in relatively homogenous formation with good drillability. This bit is designed with floating  bearing and rubber O ring seal, and also utilizes optimized cutting structure and enhanced gage protection technology and therefore, it can achieve longer footage and higher ROP. bearing and rubber O ring seal, and also utilizes optimized cutting structure and enhanced gage protection technology and therefore, it can achieve longer footage and higher ROP.

The best rotary speed range for SKF series bit is from 180 to 40 rpm, and the bit is the ideal choice for vertical drilling in upper sections, kick off sections in directional drilling and inclined section drilling applications. |

|

|

|

|

|

SKH journal bearing O-ring seal bit

SKH series bit adopts journal bearing rubber O-ring seal along with more aggressive cutting structure. This bit features longer footage and  higher ROP and is the ideal choice for drilling applications in upper homogenous formations. higher ROP and is the ideal choice for drilling applications in upper homogenous formations. |

|

|

|

|

|

SKG roller bearing O-ring seal bit

SKG series bit is designed with roller bearing and rubber O-ring seal. This bit can achieve longer footage and higher ROP when drilling  under medium to low WOB and high RPM. under medium to low WOB and high RPM. |

|

|

|

SKW non-sealed bit

SKW series product is non-sealed roller bearing bit. This bit is suitable for surface hole drilling for every kind of wells and upper sections  with good drillability. It’s advantages including low cost and high ROP, etc. with good drillability. It’s advantages including low cost and high ROP, etc. |

Diamond bits for oil

KM1944

IADC Code : M223

Bit Specifications:

Bit size: - - - - - - - - - - - - - - - - - - - 8 1/2 in

Blade count: - - - - - - - - - - - - - - - - - - - 4 pcs

Main cutter size: - - - - - - - - - - - - - - - - Φ19mm

Number of nozzles: - - - - - - - - - - - - - - - - - 4 pcs

Gage length: - - - - - - - - - - - - - - - - - - 85mm

Shank: - - - - - - - - - - - - - - - - - - 4 1/2 API Reg.

Make up torque (KN.m): - - - - - - - - - - - - 16.6-23.7

Junk slot area: - - - - - - - - - - - - - - - 11087in2

Recommended drilling parameters:

Rotary speed(rpm): - - - - - - - - - - - - - - - - - 50--260

WOB(KN):- - - - - - - - - - - - - - - - - 30--120

Flow rate(L/s): - - - - - - - - - - - - - - - - - - - 25--35

Structure features and applications of the bit:

1. Optimally designed bit profile for drilling soft to medium formations.

2. Cutting structure is force balanced and bit blade is asymmetrically designed so that the load on bit is balanced that resulting better stability of the bit.

3. Main cutters are 19.05mm high performance PDC cutters to insure service life of the bit while improving ROP.

4. Cutter exposure is optimized to insure the bit can achieve higher ROP in soft to medium formations.

5. Deep junk slot design to enhance cuttings removal ability of the bit in order to obtain high ROP.

6. Hydraulic system of the bit is optimized using dynamic flow pattern simulation technology to enhance cleaning and cooling effects of the bit to effectively prevent bit from balling.

7. The bit is designed with longer gage for better angle holding ability and better stability.

KM1952A

IADC Code: M423

Bit Specifications:

Bit size: - - - - - - - - - - - - - - - - - - - 12 1/4 in

Blade count: - - - - - - - - - - - - - - - - - - - 5 pcs

Main cutter size: - - - - - - - - - - - - - - - - Φ19mm

Number of nozzles: - - - - - - - - - - - - - - - - - 7 pcs

Gage length: - - - - - - - - - - - - - - - - - - 64mm

Shank: - - - - - - - - - - - - - - - - - - 6 5/8 API Reg.

Make up torque (KN.m): - - - - - - - - - - - - 49.6-51.4

Junk slot area: - - - - - - - - - - - - - - - 21539in2

Recommended drilling parameters:

Rotary speed(rpm): - - - - - - - - - - - - - - - - - 50--260

WOB(KN): - - - - - - - - - - - - - - - - - 30--140

Flow rate(L/s): - - - - - - - - - - - - - - - - - - - 30--70

Structure features and applications of the bit:

1. Optimally designed bit profile suitable for drilling medium formation.

2. Cutting structure is force balanced and bit blade is asymmetrically designed so that the load on bit is balanced which resulting better stability of the bit.

3. Multiple types of high performance PDC cutters are strategically arranged on bit for improved service life of the bit.

4. Shock absorbers are designed to make the bit capable of drilling through formations with hard stringers.

5. Hydraulic system of the bit is optimized using dynamic flow pattern simulation technology to enhance cleaning and cooling effects of the bit to effectively prevent bit from balling.

KS1952SG

IADC Code: S323

Bit Specifications:

Bit size: - - - - - - - - - - - - - - - - - - - 8 1/2 in

Blade count: - - - - - - - - - - - - - - - - - - - 5 pcs

Main cutter size: - - - - - - - - - - - - - - - - Φ19mm

Number of nozzles: - - - - - - - - - - - - - - - - - 5 pcs

Gage length: - - - - - - - - - - - - - - - - - - 64mm

Shank: - - - - - - - - - - - - - - - - - - 4 1/2 API Reg.

Make up torque (KN.m): - - - - - - - - - - - - 16.6-23.7

Junk slot area: - - - - - - - - - - - - - - - 12426in2

Recommended drilling parameters:

Rotary speed(rpm): - - - - - - - - - - - - - - - - - 50--260

WOB(KN): - - - - - - - - - - - - - - - - - 20--100

Flow rate(L/s): - - - - - - - - - - - - - - - - - - - 25--35

Structure features and applications of the bit:

1. The bit is optimally designed with medium profile which is suitable for soft to medium soft formations.

2. Cutting structure is force balanced, bit blade is asymmetrically designed, and spiral blade and spiral gage are also designed so that the load on bit is balanced that resulting better stability of the bit.

3. Multiple types of high performance PDC cutters are strategically arranged on the bit for improved service life of the bit.

4. Shock absorbers are designed to make the bit capable of drilling through formations with hard stringers.

5. Hydraulic system of the bit is optimized using dynamic flow pattern simulation technology to enhance cleaning and cooling effects of the bit to effectively prevent bit from balling.

6. Erosion on bit surface is effectively prevented by utilizing hardfacing material of highly erosion resistant and applying advanced base metal enhancement technology.

7. Ports on bit are also optimally designed to prevent erosion of water courses inside the bit.

KS1952SGA

IADC Code: S424

Bit Specifications:

Bit size: - - - - - - - - - - - - - - - - - - - 12 1/4in

Blade count: - - - - - - - - - - - - - - - - - - - 5 pcs

Main cutter size: - - - - - - - - - - - - - - - - Φ19mm

Number of nozzles: - - - - - - - - - - - - - - - - - 7 pcs

Gage length: - - - - - - - - - - - - - - - - - - 64mm

Shank: - - - - - - - - - - - - - - - - - - 6 5/8 API Reg.

Make up torque (KN.m): - - - - - - - - - - - - 49.6-51.4

Junk slot area: - - - - - - - - - - - - - - - 24413in2

Recommended drilling parameters:

Rotary speed(rpm): - - - - - - - - - - - - - - - - - 50--260

WOB(KN): - - - - - - - - - - - - - - - - - 30--140

Flow rate(L/s): - - - - - - - - - - - - - - - - - - - 30--0

Structure features and applications of the bit:

1. Bit profile is optimized and is suitable for drilling soft to medium formations.

2. Cutting structure is force balanced, bit blade is asymmetrically designed, and spiral blade and spiral gage are also designed so that the load on bit is balanced which resulting better stability of the bit.

3. Multiple types of high performance PDC cutters are strategically arranged on bit for improved service life of the bit.

4. Shock absorbers are designed to make the bit capable of drilling through formations with hard stringers.

5. Hydraulic system of the bit is optimized using dynamic flow pattern simulation technology to enhance cleaning and cooling effects of the bit to effectively prevent bit from balling.

6. Erosion on bit surface is effectively prevented by utilizing hardfacing material of highly erosion resistant and applying advanced base metal enhancement technology.

7. Ports on bit are also optimally designed to prevent erosion of water courses inside the bit.

Oil-Well-Drill-Bit

Drill-product-series

Tricone drill bit Product exhibition

Diamond bits for oil

Other-oilfield-products

|