|

|

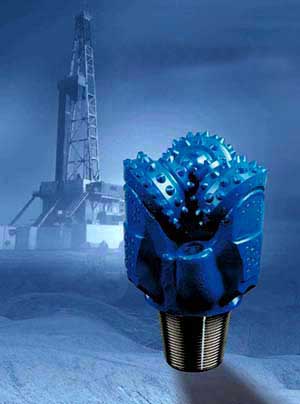

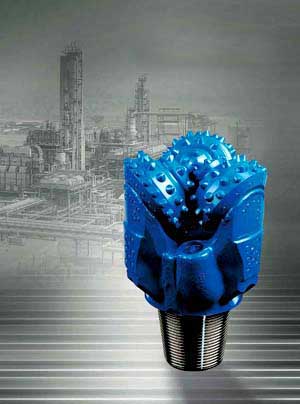

Kingdream roller cone bit |

|

Kingdream Public Limited Company (Jianghan Petroleum Administrative Bureau holds its majority stocks) is one of the key New & Hi-tech enterprises as well as the first-class enterprises in China. It is the largest manufacturing base in Asia for making various bits for oil well drilling and mining. In 1998, Kingdream was listed in Shenzhen Stock Exchange of China. Its stock code is 000852. Kingdream's roller cone bits for oil well drilling take up over 60% of domestic market and are exported to more than 20 countries and areas, such as USA, Canada, Iran, and Russia, etc.

Kingdream Public Limited Company started to use advanced J, X and R series bit manufacturing technology from abroad in 1982, and then successively introduced ATJ, ATM, ATX, MAX and GT series bit technologies. Through more than 20 years of fruitful research, not only the introduced bit products have been improved, but lots of bit technologies with the company's own intellectual property rights have also been developed, such as floating bearing, full bottom hole coverage, double water course, equally worn compacts, and single cone bit technologies, etc. Kingdream roller cone bits for oil well drilling have novel structures and complete varieties including 9 standard series, 25 sizes and more than 600 types which can be used for drilling various formations from soft to very hard.

Nomenclature of Kingdream roller cone bits for oil well drilling

1 Bit diameter code: indicated by numbers (integer or fraction). The numbers indicate diameter of the bit in inches.

2 Bit series code: for tri-cone bit, 9 standard series are designated based on main features of the bearing and sealing structures. Apart from bearing and seal, a major modification to bit structure will be defined as a special structure, and standard series plus special structure or the combination of special structures makes the special series. The series code of single cone bit is indicated by "Y*". "Y" means one cone, and "*" is the design number, which indicates different design features. The series codes of oil well drilling bits are shown in the following table.

Series codes of oil well drilling bits:

|

Serial No. |

Main features of the bearing and seal |

Standard series |

Special series |

|

T(Special gage protection) |

S(Full bottom hole coverage) |

|

1 |

Rubber O ring sealed journal bearing |

HA |

HAT |

HAS |

|

2 |

Metal face sealed journal bearing |

HJ |

HJT |

HJS |

|

3 |

Rubber O ring sealed roller bearing |

GA |

GAT |

GAS |

|

4 |

Metal face sealed roller bearing |

GJ |

GJT |

GJS |

|

5 |

Rubber O ring sealed floating bearing |

FA |

FAT |

FAS |

|

6 |

Metal face sealed floating bearing |

FJ |

FJT |

FJS |

|

7 |

KINGMIGHT |

E |

|

|

|

8 |

Single cone bit with rubber O ring sealed journal bearing |

YA |

|

|

|

9 |

Single cone bit with rubber O ring sealed journal bearing (improved) |

YC |

|

|

|

10 |

Non-sealed roller bearing |

W |

|

|

3 Bit classification code: According to the regulations in SPE/IADC 23937, bit classification code consists of three digits, the first digit stands for cutting structure and formation code, the second one stands for stratigraphic classification code, and the last digit stands for rock bit structure feature code.

4 Additional structure features of the bit: When bits need to be improved or to be reinforced to meet the special requirement of drilling application and formation, the additional structure features indicated by one or more letters will be added to the classification code. See the following table:

Table: Additional structure features of the bit

|

Code |

Additional structure features |

|

C |

Center nozzle |

|

H |

Diamond gage protection |

|

E |

Extended nozzle recess |

|

G |

Reinforced bit head OD |

|

L |

Bit head OD stabilization pad |

|

Y |

Conical carbide insert |

For example: an 8-1/2 HJT537GL tri-cone bit

8 1/2: Bit diameter is 8-1/2 inches (215.9mm);

HJT: Metal face sealed journal bearing, special gage protection;

537: Insert bit for drilling in soft to medium hard formation with low compressive strength;

G: Reinforced bit head OD;

L: Bit head OD stabilization pad.

Kingdream Roller Cone Bit for Shallow Oil Well Drilling

Kingdream roller cone bits for shallow oil well drilling are manufactured by Shanghai Kingdream Sub-company. The product sizes are from 8-1/2" to 26" including 3 series and nearly 200 types. Bit sizes from 8-1/2" to 12-1/4" are suitable for drilling upper sections within 2,000 meters depth, while bit sizes from 13-5/8" to 26" can be used to drill various formations from soft to extremely hard.

Nomenclature of Kingdream roller cone bits for shallow oil well drilling

1 Bit diameter code:indicated by numbers (integer or fraction). The numbers indicate diameter of the bit in inches.

2 Bit series code:for tri-cone bit, three standard series are designated based on main features of the bearing and sealing structures. Apart from bearing and seal, a major modification to bit structure will be defined as a special structure, and standard series plus special structure or the combination of special structures makes the special series, as shown by the following table:

table: Kingdream Roller Cone Bit for Shallow Oil Well Drilling

|

Serial No. |

Main features of the bearing and seal |

Standard series |

Special series |

|

1 |

Rubber O ring sealed journal bearing |

SKH |

SKHT |

|

2 |

Rubber O ring sealed roller bearing |

SKG |

SKGT |

|

3 |

Non-sealed roller bearing |

SKW |

| |

|

HA series bit for oil well drilling |

|

Main structure features:

1 Journal bearing. Head bearing surfaceis hardfaced. Cone bearing is inlaid with friction reducing alloy and then silver-plated. The load capacity and seizure resistance of the bearing is greatly improved.

2 O ring seal is made of high saturated buna-N with the more wear resistance. The increased seal section and precisely designed sealing flange in the cone sealing area increases the reliability of the seal.

3 The bit bearing can be ball locked or ring locked. Bit with ring lock bearing can stand high weight on bit and bit with ball lock bearing can be applied to high rotary speed drilling.

4 All-rubber compensator is used which can limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication.

5 New type of grease that can sustain high temperature up to 250ºC is utilized.

6 High wear resistance and excellent cutting ability of the insert bit are given by using carbide compacts with high strength and high toughness in combination with optimized number of compacts and rows, compact exposure height and special shaped compacts. For steel tooth bit, the tooth surface is hardfaced with new type of wear resistant material and thus working life of the cutting structure is exterded while high ROP is also maintained.

Product predominance:HA series bit is O-ring sealed journal bearing product. It can sustain higher WOB under normal rotary speed and is suitable for drilling formations from very soft to very hard by properly selecting different cutting structures.

Available sizes and types of HA series tri-cone bits: HA116, HA117, HA126, HA127, HA136, HA137, HA216, HA217, HA417, HA437, HA447G, HA517G, HA527G, HA537G, HA617G, HA637G,etc.

|

|

HJ series bit for oil well drilling |

|

Main structure features:

1 High precision journal bearing with two thrust faces. Head bearing surface is hardfaced. Cone bearing is inlaid with friction reducing alloy and silver-plated. The load capacity and seizure resistance of the bearing is greatly improved.

2 Precise metal face seal. The two dynamic axial sealing rings of the sealing system are metal seals, and two highly elastic rubber energizers are seated separately in head and cone sealing areas functioning as static seals. Optimized sealing compression ensures good contact between the two metal sealing faces at all times.

3 Ball locked cone, suitable for high rotary speed.

4 All-rubber compensator is used which can limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication.

5 New type of wear resistant grease that can sustain high temperature up to 250ºC is utilized.

6 High wear resistance and excellent cutting ability of the insert bit are given by using carbide compacts with high strength and high toughness in combination with optimized number of compacts and rows, compact exposure height and special shaped compacts. For steel tooth bit, the tooth surface is hardfaced with new type of wear resistant material and thus working life of the cutting structure is extended while high ROP is also maintained.

Product predominance:HJ series bit uses the most advanced sealing technology in the world, i.e. the metal face seal (MFS). It can perform consistently in high speed drilling applications, and is the ideal tool for drilling directional and horizontal wells. In comparison with conventional rubber O-ring sealed bits, the average working life (total drilling hours) of HJ series bit under the condition of the same operating parameters can be increased by 35%.

Available sizes and types of HJ series tri-cone bits:HJ117, HJ127, HJ137, HJ417, HJ437, HJ447G, HJ517G, HJ527G, HJ537G, HJ547G, HJ617G, HJ627G, HJ637G, HJ737G,etc.

|

|

GA series bit for oil well drilling |

|

Main structure features

1. Sealed roller bearing structure. With rollers arranged in grooves recessed in the cone body, the size of the bearing journal is increased.

2. Thrust bearing surfaces are hardfaced and treated with friction reducing technology.

3. All-rubber compensator is used to limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication.

4. Ball locked cone, suitable for high rotary speed.

5. New type of wear resistant grease that can sustain high temperature up to 250 degree is utilized.

Product predominance:GA series bit is rubber O-ring sealed roller bearing bit, which is the economical and ideal tool for drilling applications where high RPM and medium to low WOB are required.

Available sizes and types of GA series tri-cone bits: GA114, GA115, GA124, GA125, GA134, GA135, GA214, GA215, GA415, GA435, GA515G, GA535G,etc.

|

|

GJ series bit for oil well drilling |

|

Main structure features:

1. Precise metal face seal. The two dynamic axial sealing rings of the sealing system are metal seals, and two highly elastic rubber energizers are seated separately in head and cone sealing areas functioning as static seals. Optimized sealing compression ensures good contact between the two metal sealing faces at all times.

2. Sizes of bearing journal and rollers are made larger by arranging the rollers in recesses in cone body.

3. All-rubber compensator is used which can limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication.

4. New type of wear resistant grease that can sustain high temperature up to 250¡ãC is utilized.

5. Shirttail and head OD are hardfaced for enhanced gage protection. Center nozzle is equipped for bits of larger sizes.

Product predominance:GJ series bit is metal face sealed roller bearing bit. Using metal face seal (MFS)--the most advanced sealing technology in the world, this series of bit can perform consistently in drilling applications where high RPM and medium to low WOB are required, and is the ideal tool for downhole motor drilling and high rotary speed drilling applications.

Available sizes and types of GJ series tri-cone bits: GJ115, GJ135, GJ415, GJ435, GJ515G, GJ535G,etc.

|

|

FA series bit for oil well drilling |

|

Main structure features:

1. Floating bearing structure. The floatingelements are made of new materials with high strength, high elasticity, high wear resistance and can endure high temperature, and bearing surface is treated with solid lubricant. This decreases the relative linear velocity of the bearing couple and reduces the temperature of the friction surfaces, which results in improved reliability and working life of the bearing under large WOB and high RPM conditions.

2. The O-ring seal is made of high-saturated buna-N with good wear resistance and which can endure high temperature. The increased seal section reduces unit pressure on the seal, and finely designed sealing flange increases reliability of the seal.

3. Ball locked cone, suitable for high rotary speed.

4. All-rubber compensator is used to limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication.

5. New type of wear resistant grease that can sustain high temperature up to 250 degree is utilized.

6. High wear resistance and excellent cutting ability of the insert bit are given by using carbide compacts with high strength and high toughness in combination with optimized number of compacts and rows, compact exposure height and special shaped compacts. For steel tooth bit, the tooth surface is hardfaced with new type of wear resistant material and thus working life of the cutting structure is extended while high ROP is also maintained.

Product predominance:FA series tri-cone bits are O-ring sealed floating bearing products. This series of bits are suitable for high RPM and high WOB drilling applications and they can be used to drill formations from very soft to very hard by selecting proper cutting structures.

Available sizes and types of FA series tri-cone bits: FAT127, FA437, FA447G, FA5117G, FA537G, FAT617G, FAT637G, FAT737G,etc.

|

|

FJ series bit for oil well drilling |

|

Main structure features:

1. Floating bearing structure. The floating elements are made of new materials with high strength, high elasticity, high wear resistance and can endure high temperature, and bearing surface is treated with solid lubricant. This decreases the relative linear velocity of the bearing couple and reduces the temperature of the friction surfaces, which results in improved reliability and working life of the bearing under large WOB and high RPM conditions.

2. Precise metal face sealed. The two dynamic axial sealing rings of the sealing system are metal seals, and two highly elastic rubber energizers are seated separately in head and cone sealing areas functioning as static seals. Optimized sealing compression ensures good contact between the two metal sealing faces at all times.

3. Ball locked cone, suitable for high rotary speed.

4. All-rubber compensator is used to limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication.

5. New type of wear resistant grease that can sustain high temperature up to 250 degree is utilized.

6. High wear resistance and excellent cutting ability of the insert bit are given by using carbide compacts of high strength and high toughness in combination with optimized number of compacts and rows, compact exposure height and special shaped compacts. For steel tooth bit, the tooth surface is hardfaced with new type of wear resistant material and thus working life of the cutting structure is extended while high ROP is also maintained.

Product predominance:By combining advantages of both HJ and FA series bits, FJ series bits are ideal tools for drilling applications where high RPM and high WOB are needed. In addition to conventional formations, this series of bit can also drill effectively in non-homogeneous formations with stringers and higher impact vibrations.

Available sizes and types of FJ series tri-cone bits: FJ117, FJT127, FJ437, FJ447G, FJ517G, FJ537G, FJ617G, FJ637G, FJ737G,etc.

|

|

"KingMight" E series roller cone bit

for oil well drilling |

|

"KingMight" E series roller cone bit is developed on the basis of Kingdream FJ series product, and it is a new series bit that combines special T and S features as well as head OD active gage protection and side cutting technologies. It is suitable for high RPM and high WOB drilling applications and features long service life, and is the ideal tool for drilling directional wells, horizontal wells and high temperature deep wells.

Main structure features

1. Floating bearing structure. The floating elements are made of new materials with high strength, high elasticity, high wear resistance and can endure high temperature, and bearing surface is treated with solid lubricant. This decreases the relative linear velocity of the bearing couple and reduces the temperature of the friction surfaces, which results in improved reliability and working life of the bearing under large WOB and high RPM conditions.

2. Precise metal face seal. The two dynamic axial sealing rings of the sealing system are metal seals, and two highly elastic rubber energizers are seated separately in head and cone sealing areas functioning as static seals. Optimized sealing compression ensures good contact between the two metal sealing faces at all times.

3. Ball locked cone, suitable for high rotary speed.

4. All-rubber compensator is used to limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication.

5. New type of wear resistant grease that can sustain high temperature up to 250 degree is utilized.

6. Advanced secondary cutter technology (i.e. special S structure feature) is used, which solves the problem of low bott, om hole coverage coefficient normally found with conventional insert bit and effectively increases the cutting ability of bit and wear resistance of the cone shell.

7. Friction force and friction heat generated on the base of cone gage due to contacting with borehole wall while the bit is working is reduced by exposing gage compacts to a certain height, and working life of the bearing seal is consequently extended.

8. Inequable spaced compacts arrangement, and optimized number of rows, number of compacts and compact exposure. Offset crested scoop compacts are used for drilling soft formations.

9. Carbide compacts are fitted with certain exposure on side of the bit head and trimmers are equipped on cone (i.e. special T structure feature) so that the side cutting ability of bit is greatly improved and the perfect well bore quality can be ensured.

Available sizes and types of "KingMight" E series roller cone bits: E517G, E537G,etc.

|

|

YA series single cone bit for oil well drilling |

|

Main structure features:

1. Using two-stage gage protection of the cone and bit body, and with active cutting gage protection compacts and passive anti-friction gage protection compacts on bit body, the bit has good gage protection and up reaming abilities.

2. Staggered , compacts arrangement on cone, and optimized cone shape, the number of the rows, number of compacts as well as compact exposure height.

3. Two-watercourse (main and auxiliary) structure is used for the hydraulic system with a jet nozzle and a divergent nozzle. The nozzle combination is optimized.

4. The advanced high-saturated buna-N rubber seals are used for journal and bearing pin sealing, and optimized sealing compression and special gage protection design ensure the reliability of the bearing seal.

5. Performance of the bearing is improved by applying hardfacing layer on head bearing surface and inlaying friction reducing alloy on surface of cone ID.

6. Ball locked cone makes the bit being applicable to high RPM.

Product predominance :It can be used widely, not only for side tracking, but also for deep hole drilling.Its working torque is lower than that of PDC bit under the same WOB and formation conditions, thread expanding problem normally encountered with small size drilling tools can be reduced and consequently, the downhole accident is avoided. By combining advantages of both tri-cone and PDC bits and eliminating deficiencies of the both, the single cone bit is more suitable for drilling formations with high strength and plasticity than tri-cone bit, and more suitable for drilling tough formations with hard stringers and other complicated formations than PDC bit. The bit can meet requirements of high speed and other special drilling applications when used with downhole motor drilling tools. Simple structure, large bearing clearance, high reliability, and bit size easy to be designed smaller.

Available sizes and types of YA series single cone bits: YA437, YA517, YA537,etc.

|

|

YC series enhanced single cone bit

for oil well drilling |

|

Main structure features

1. With advanced step structure of the cone, equal worn of the compacts in permanent contact area and alternative contact area of the bit is realized.

2. In response to the fact that compacts in different areas on the cone have different cutting actions, conical compacts are set in permanent contact area and wedge compacts are set in alternative contact area so that the drilling efficiency is greatly improved.

3. Wear resistance of the cutting structure is enhanced by setting PDC cutters in the permanent contact area of the cone where compacts are most severely worn.

4. Carbide compacts are equipped on cone top surface to protect cone base material from erosion.

5. Bit cutting structure is designed, verified and simulated by using advanced single cone bit kinematics computation software and bottom-hole trajectory simulation software so that coverage coefficient of the bit on bottom-hole is increased.

6. Optimized hydraulics structure improves the cleaning ability and increases ROP.

7. Small angled lower watercourse design increases head OD thickness and can effectively prevent watercourse erosion.

8. The bit has excellent gage protection and up reaming abilities by setting active cutting conical spherical gage compacts on gage pad of the head.

Product predominance: It can be used widely, not only for side tracking, but also for deep hole drilling. Its working torque is lower than that of PDC bit under the same WOB and formation conditions, thread expanding problem normally encountered with small size drilling tools can be reduced and consequently, the downhole accident is avoided. By combining advantages of both tri-cone and PDC bits and eliminating deficiencies of the both, the single cone bit is more suitable for drilling formations with both high strength and plasticity than tri-cone bit, and more suitable for drilling tough formations with hard stringers and other complicated formations than PDC bit. The bit can meet requirements of high speed and other special drilling applications when used in combination with downhole motor drilling tools. Simple structure, large bearing clearance, high reliability, and bit size easy to be designed smaller. Service life of the bit is extended due to the utilization of PDC cutters.

Available sizes and types of YC series single cone bits: YC437, YC517, YC537,etc.

|

|

SKH series roller cone bit for shallow oil well drilling |

|

The structure features

1. Increasing the impact resistance of compacts and decreasing the breakage rate by using the tungsten carbide compacts with high strength and toughness. For soft formation drilling, offset crested scoop compacts are used.

2. Improving the seizure resistance and load capacity of the bearing by applying carbide layer on head bearing surface and silver-plating in the ID of cone.

3. Increasing the reliability of bearing seal by using high-saturated buna-N rubber O ring seal with larger cross section. A seal boss is added to the outer end of the sealing area.

4. Being able to stand high RPM by using ball locked cone.

5. Taking good advantage of the cutting ability and cutting speed by optimizing the design of number of compacts and rows, cempact exposure height and the special shaped compacts.

6. Providing the bearing system with good lubrication, extending the bit life and ensuring the normal work of the O-ring seal by using all-rubber compensator to limit the pressure differential and prevent drilling fluid from entering into bearing lubrication system.

7. Increasing the high temperature resistance of the seal & lube system by using new type of grease with low abrasive wear, which can stand high temperature up to 250ºC.

Available sizes and types of SKH series roller cone bits: SKH116, SKH126, SKH136, SKH137, SKH216, SKH217, SKH437, SKH517, SKH537,etc.

|

|

SKG series roller cone bit for

shallow oil well drilling |

|

The structure features:

SKG series bit is of O-ring sealed roller bearing structure, it is the ideal and economical tool for high RPM drilling applications. Its main characteristics include:

1. Sealed roller bearing structure. Rollers are arranged in recesses in the cone body and therefore size of the bearing journal is enlarged, so that it can adapt for higher WOB and RPM.

2. Surfaces of the thrust bearing couple are specially treated for decreasing friction and increasing rigidness, load capacity of the bit and anti-galling ability of the bearing are consequently improved.

Available sizes and types of SKG series roller cone bits: SKG114, SKG124, SKG134, SKG214, SKG435, SKG515, SKG535,etc

|

|

SKW series roller cone bit

for shallow oil well drilling |

|

The structure features

SKW series bit is of non-sealed roller bearing structure, it is the ideal and economical tool for high RPM and geothermal drilling applications. Its main characteristics include:

1. For bit size of 12-1/4" and larger, bearing structure of roller-ball-roller-thrust is utilized.

2. For bit smaller than 12-1/4", bearing structure of roller-ball-pin slide-thrust is used and it is suitable for high RPM.

3. Without bearing seal, drilling fluid can enter the bearing cavity directly to cool the bearing, and it is suitable for geothermal drilling.

Available sizes and types of SKW series roller cone bits: SKW111, SKW121, SKW131, SKW211, SKW241,etc.

|

Company Main Products

Roller cone bits for

MD high speed motor bit

MINI-MD cone bit for slim hole drilling applications

SUPER-MD super-high speed motor bit

HF bit for hard formations

SWT steel tooth bit with high efficiency

A series bit for air drilling

HJ metal sealed bit with journal bearing

GJ metal sealed bit with roller bearing

HA rubber sealed bit with journal bearing

GA rubber sealed bit with roller bearing

YC Series single cone bit

SKF series floating bearing O-ring seal tri-cone bit

SKH journal bearing O-ring seal bit

SKG roller bearing O-ring seal bit

SKW non-sealed bit

Diamond bits for oil (PDC bit)

KM1944

KM1952A

KS1952SG

KS1952SGA

Catalouge-of-kingdream-drill-bits-2010-04-29.pdf

Other-oilfield-products

Oil-Well-Drill-Bit-Main-Products

And if you have some enquiries on bits for your power project, oil, gas and geothermal projects and others, please contact:

[email protected]

|