|

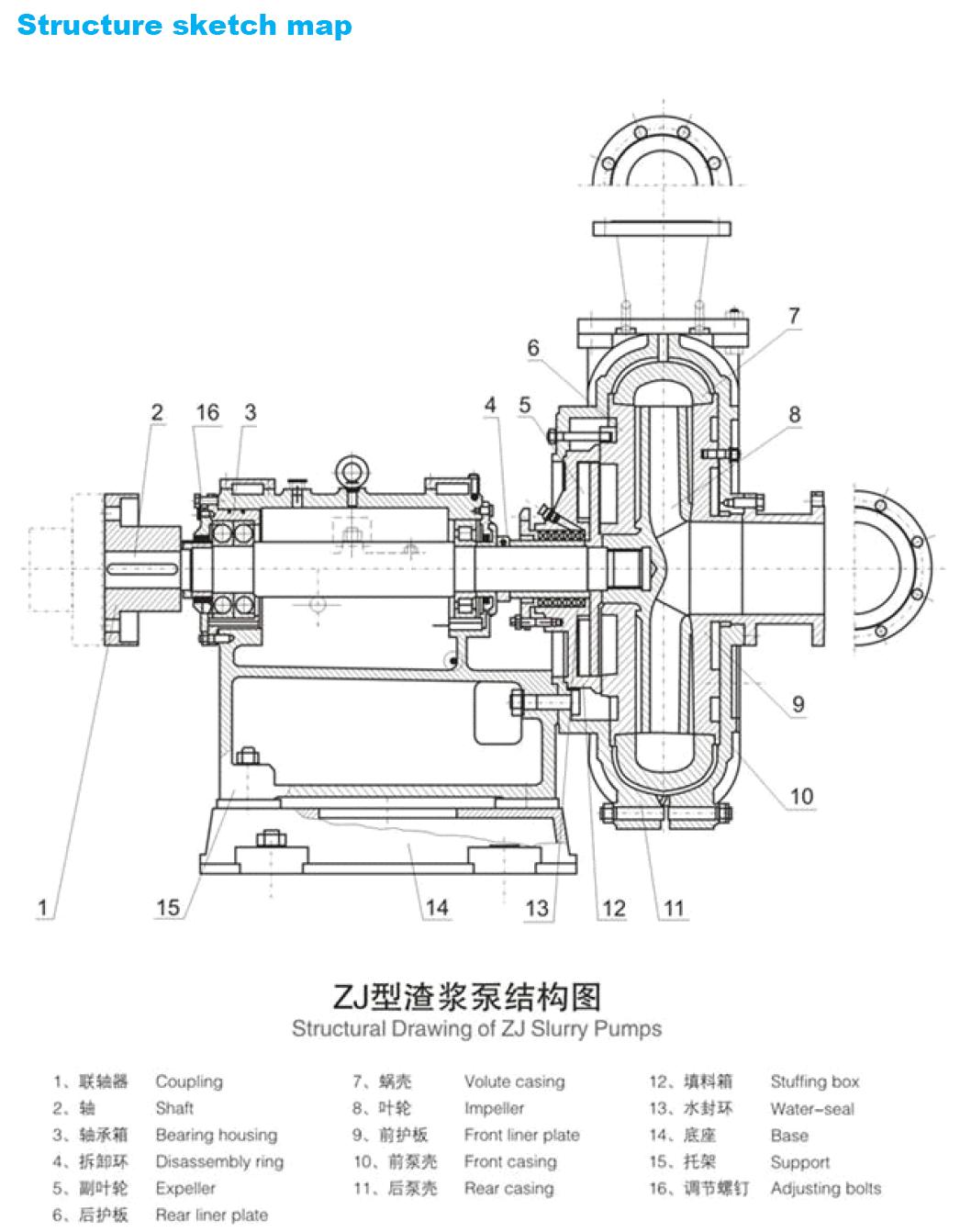

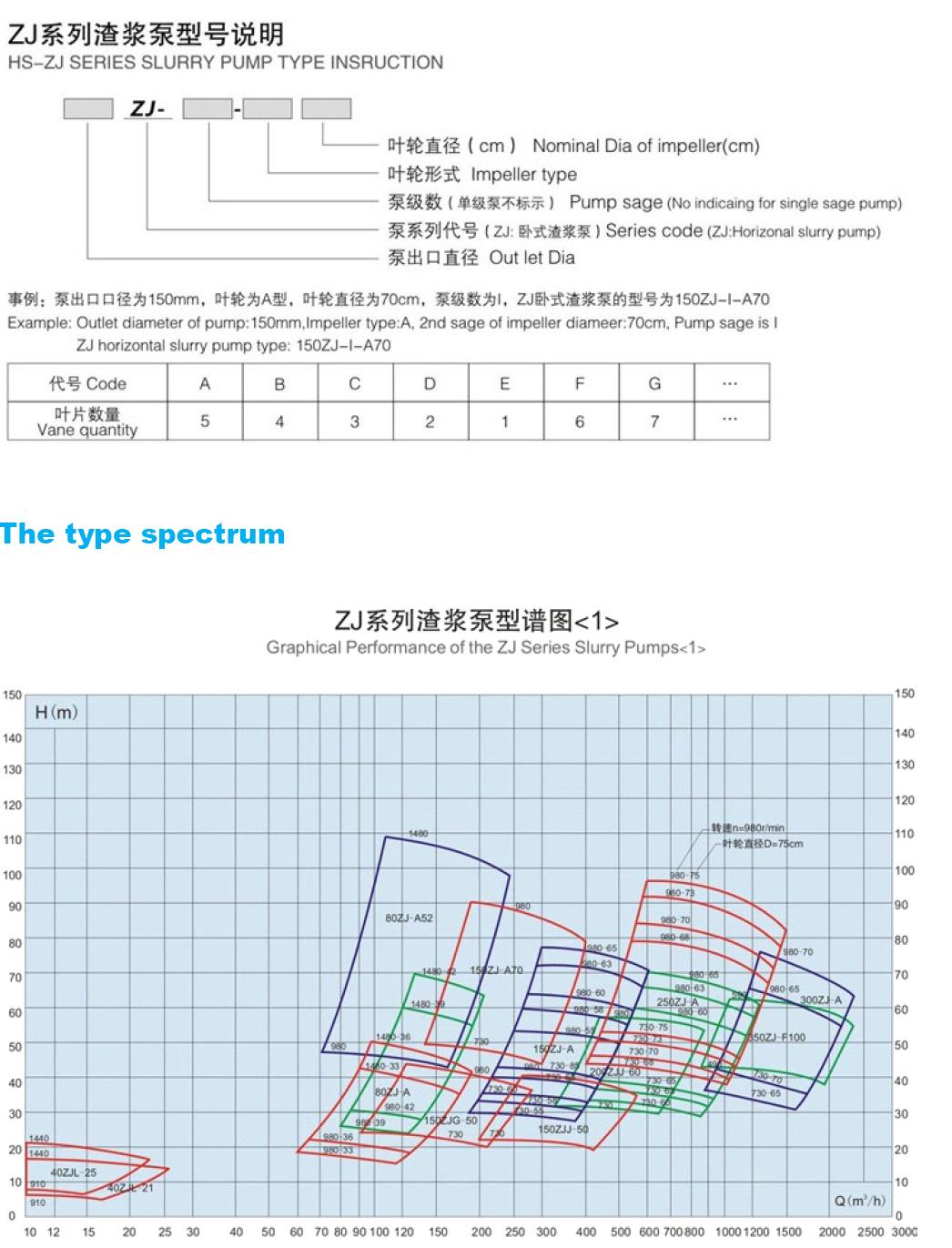

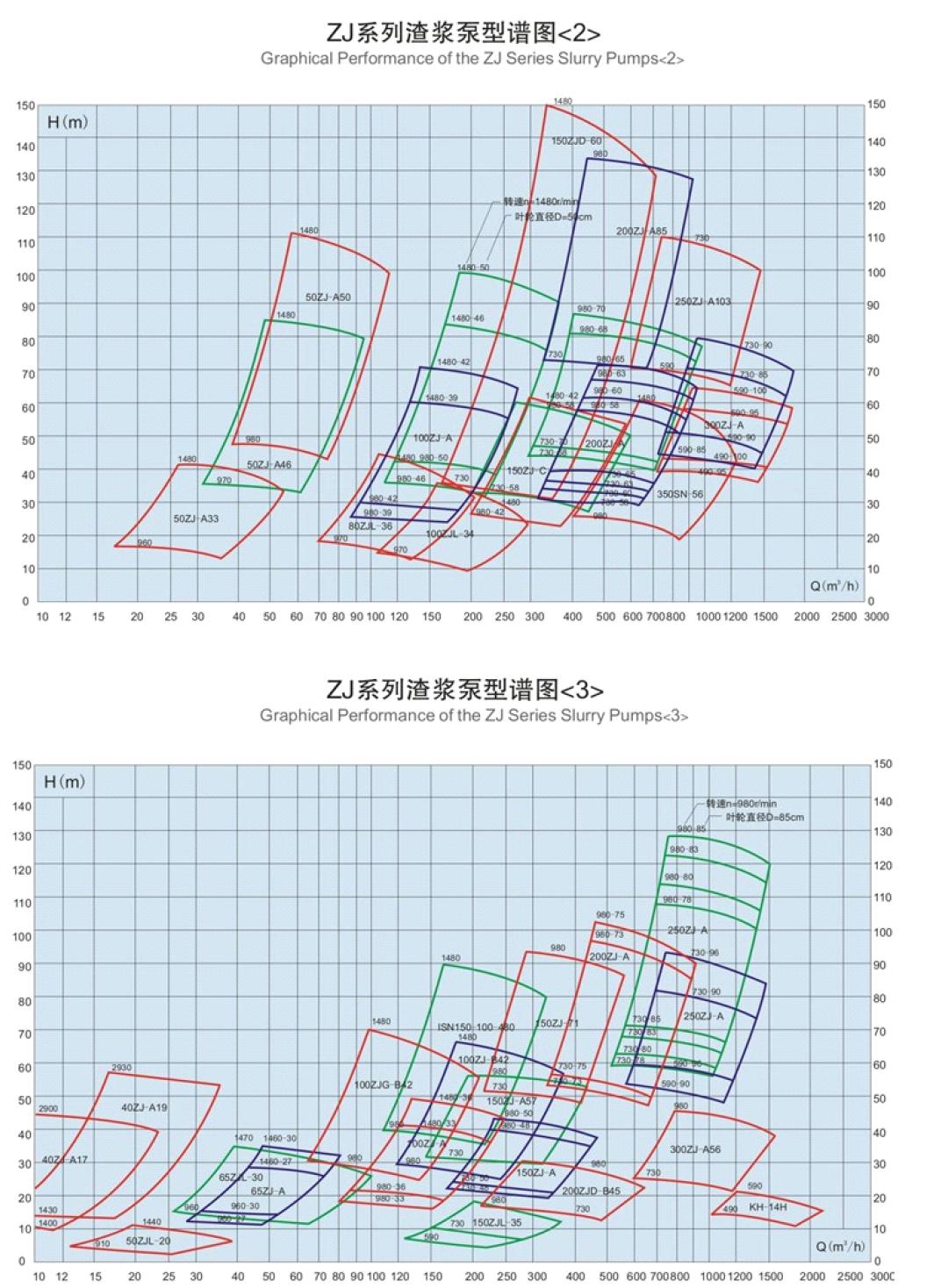

ZJ Series Pumps

Main technical parameters

Flow: 12~5040m3/ h;

Lift: 5~118m;

Speed: 300~3800r / min;

Caliber: 25~400;

Temperature range: up to 80ďż˝?

Product overview

ZJ type horizontal slurry pump is energy-efficient products which widely absorb the domestic and foreign advanced technology of similar products. The series slurry pump and hydraulic design has reasonable structure and design for it adopts international advanced solid-liquid two-phase fluid theory according to the principle of minimum loss design. Its over-current components geometrical shape correspond with the medium flow state, which reduces the eddy current and the impact of local and the hydraulic loss, thus reduce the flow components wear, improve hydraulic efficiency, and reduce running noise and vibration. The pump over-current components adopt high alloy cast iron or hard rubber which has high abrasion resistance, corrosion resistance, impact resistance, thereby improve its service period. Moreover, this series pump uses power step-down to ensure that the slurry is not easy to leak. Some advantages of ZJ pumps are high efficiency, light weight, low noise, reliable operation, long service life, convenient repair and other significant characteristics. This series of pumps can also use multi-stage parallel or composite operation mode for different process needs. The product performance indicators have reached domestic leading level.

Working conditions

Speed: motor direct drive 2900/1480/980/730/590(r/min)

Belt wheel direct drive to meet customer requirements

Medium temperature less than 80ďż˝? in general, special to 110 ďż˝?/DIV>

The mixture of solid and liquid concentration by weight: mortar concentrations below 45%, slurry concentration is less than or equal to 60%

Flow range: 4.5~2339 m3/h

Lift range: 6~133 m

Main uses

ZJ series slurry pump is widely used in electric power, metallurgy, coal, building, chemical and other industries, for conveying the abrasive and corrosive slurry containing solid particles. The solid-liquid mixture maximum weight concentration, mortar 45%,slurry 60%.

With full size, ZJ pumps can be used directly, belt, hydraulic coupler, variable speed drive form, or can also be used in series or parallel operation based on user needs.

Technical parameters

ZJ series slurry pump performance table 1:

|

Type |

R.S. n |

Water properties |

Matching motor |

|

r/min |

Flow Q |

Lift H |

Shaft power P |

Maximum efficiency η |

NPSH |

Type |

Power / voltage |

|

m3/h |

m |

KW |

% |

m |

KW/V |

|

300ZJ-I-A100 |

590 |

913 |

65.2 |

243 |

66.7 |

4.1 |

Y450-10 |

315/6000 |

|

1785 |

59.7 |

361 |

80.4 |

Y500-10 |

450/6000 |

|

1826 |

59.3 |

365.4 |

80.7 |

Y500-10 |

450/6000 |

|

490 |

758 |

45 |

139.3 |

66.7 |

3 |

Y450-12 |

185/6000 |

|

1482 |

41.2 |

206.8 |

80.4 |

Y450-12 |

250/6000 |

|

1517 |

40.9 |

209.4 |

80.7 |

Y450-12 |

250/6000 |

|

300ZJ-I-A95 |

590 |

867 |

58.8 |

217.9 |

63.7 |

4.1 |

Y450-10 |

280/6000 |

|

1696 |

53.9 |

321.6 |

77.4 |

Y500-10 |

400/6000 |

|

1735 |

53.5 |

325.3 |

77.7 |

Y500-10 |

400/6000 |

|

490 |

720 |

40.6 |

125 |

63.7 |

3 |

Y450-12 |

185/6000 |

|

1408 |

37.2 |

184.3 |

77.4 |

Y500-12 |

220/6000 |

|

1441 |

36.9 |

186.4 |

77.7 |

Y500-12 |

220/6000 |

|

300ZJ-I-A90 |

730 |

922 |

79.9 |

290.3 |

69.1 |

5.7 |

Y450-8 |

355/6000 |

|

1648 |

73.6 |

410.3 |

80.5 |

Y500-8 |

500/6000 |

|

1844 |

70.7 |

436.2 |

81.4 |

Y500-8 |

560/6000 |

|

590 |

745 |

52.2 |

153.3 |

69.1 |

3.9 |

Y450-10 |

185/6000 |

|

1332 |

48.1 |

216.7 |

80.5 |

Y450-10 |

280/6000 |

|

1490 |

46.2 |

230.3 |

81.4 |

Y450-10 |

280/6000 |

|

300ZJ-1-A85 |

730 |

871 |

71.3 |

255.9 |

66.1 |

5.6 |

Y450-8 |

315/6000 |

|

1556 |

65.6 |

358.7 |

77.5 |

Y450-8 |

450/6000 |

|

1742 |

63.1 |

381.8 |

78.4 |

Y450-8 |

450/6000 |

|

590 |

704 |

46.6 |

135.2 |

66.1 |

3.8 |

Y355L2-10 |

160/380 |

|

1258 |

42.9 |

189.6 |

77.5 |

Y450-10 |

220/6000 |

|

1408 |

41.2 |

201.5 |

78.4 |

Y450-10 |

250/6000 |

ZJ series slurry pump performance table 2:

|

Type |

R.S. n |

Water properties |

Matching motor |

|

r/min |

Flow Q |

Lift H |

Shaft power P |

Maximum efficiency η |

NPSH |

Type |

Power / voltage |

|

m3/h |

m |

kW |

% |

m |

kW/V |

|

300ZJ-I-A70 |

980 |

1269 |

76.8 |

368.6 |

72 |

7 |

Y450-6 |

450/6000 |

|

2118 |

66.7 |

480.9 |

80 |

Y450-6 |

630/6000 |

|

2333 |

64 |

505.8 |

80.4 |

Y450-6 |

630/6000 |

|

730 |

945 |

42.6 |

152.3 |

72 |

3.9 |

Y355L1-8 |

185/380 |

|

1578 |

37 |

198.8 |

80 |

Y400-8 |

250/6000 |

|

1738 |

35.5 |

209 |

80.4 |

Y400-8 |

250/6000 |

|

300ZJ-I-A65 |

980 |

1178 |

66.2 |

307.8 |

69 |

6.6 |

Y450-6 |

400/6000 |

|

1967 |

57.5 |

400 |

77 |

Y450-6 |

500/6000 |

|

2166 |

55.2 |

420.7 |

77.4 |

Y450-6 |

500/6000 |

|

730 |

877 |

36.7 |

127 |

69 |

3.7 |

Y355M2-8 |

160/380 |

|

1465 |

31.9 |

165.3 |

77 |

Y355L2-8 |

200/380 |

|

1614 |

30.6 |

173.8 |

77.4 |

Y400-8 |

220/6000 |

|

300ZJ-I-A56 |

980 |

789 |

46 |

148.6 |

66.5 |

5.5 |

Y355M2-6 |

185/380 |

|

1415 |

40.8 |

195.6 |

80.4 |

Y355L2-6 |

250/380 |

|

1568 |

38.8 |

204.8 |

80.9 |

Y355L2-6 |

250/380 |

|

730 |

588 |

25.5 |

61.4 |

66.5 |

3.5 |

Y315M-8 |

75/380 |

|

1054 |

22.6 |

80.7 |

80.4 |

Y315L2-8 |

110/380 |

|

1168 |

21.5 |

84.5 |

80.9 |

Y315L2-8 |

110/380 |

|

250ZJ-I-A103 |

730 |

734 |

110.5 |

366.3 |

60.3 |

4.3 |

Y450-8 |

450/6000 |

|

1067 |

106.7 |

455.5 |

69.6 |

Y500-8 |

560/6000 |

|

1573 |

98.9 |

568.7 |

74.5 |

Y500-8 |

710/6000 |

|

590 |

593 |

72.2 |

193.4 |

60.3 |

2.8 |

Y450-10 |

250/6000 |

|

/DIV> |

69.7 |

235.1 |

69.6 |

Y450-10 |

280/6000 |

|

/DIV> |

64.6 |

300.1 |

74.5 |

Y450-10 |

355/6000 |

|

250J-I-A96 |

730 |

736 |

93.7 |

290.7 |

64.6 |

5.5 |

Y450-8 |

355/6000 |

|

1076 |

90 |

356.4 |

74 |

Y450-8 |

450/6000 |

|

1466 |

84.5 |

433.6 |

77.8 |

Y500-8 |

560/6000 |

|

590 |

595 |

61.2 |

153.5 |

64.6 |

3.5 |

Y450-10 |

185/6000 |

|

870 |

58.8 |

188.3 |

74 |

Y450-10 |

250/6000 |

|

1185 |

55.2 |

229 |

77.8 |

Y450-10 |

280/6000 |

|

250ZJ-I-A90 |

730 |

690 |

82.4 |

255.5 |

60.6 |

5.3 |

Y450-8 |

315/6000 |

|

1009 |

79.1 |

310.5 |

70 |

Y450-8 |

400/6000 |

|

1374 |

74.3 |

376.7 |

73.8 |

Y450-8 |

450/6000 |

|

590 |

558 |

53.8 |

134.9 |

60.6 |

3.4 |

Y355L2-10 |

160/380 |

|

816 |

51.7 |

164.1 |

70 |

Y450-10 |

200/6000 |

|

1111 |

48.5 |

198.8 |

73.8 |

Y450-10 |

250/6000 |

|

250J-I-A85 |

980 |

752 |

128.7 |

446 |

59.1 |

5.5 |

Y450-6 |

560/6000 |

|

1248 |

124.4 |

587.2 |

72 |

Y500-6 |

710/6000 |

|

1504 |

120.4 |

652.3 |

75.6 |

Y500-6, |

800/6000 |

|

730 |

560 |

71.4 |

184.2 |

59.1 |

3.5 |

Y400-8 |

220/6000 |

|

930 |

69 |

242.7 |

72 |

Y450-8 |

315/6000 |

|

1120 |

66.8 |

269.5 |

75.6 |

Y450-8 |

315/6000 |

ZJ series slurry pump performance table 3:

|

Type |

R.S. n |

Water properties |

Matching motor |

|

r/min |

Flow Q |

Lift H |

Shaft power P |

Maximum efficiency η |

NPSH |

Type |

Power / voltage |

|

m3/h |

m |

kW |

% |

m |

kW/V |

|

250ZJ-I-A83 |

980 |

734 |

122.7 |

422.1 |

58.1 |

/DIV> |

Y450-6 |

500/6000 |

|

1219 |

118.6 |

554.5 |

71 |

505 |

Y500-6 |

710/6000 |

|

1469 |

114.8 |

615.6 |

74.6 |

/DIV> |

Y500-6 |

800/6000 |

|

730 |

547 |

68.1 |

174.6 |

58.1 |

/DIV> |

Y400-8 |

220/6000 |

|

908 |

65.8 |

229.2 |

71 |

3.5 |

Y400-8 |

280/6000 |

|

1094 |

63.7 |

254.4 |

74.6 |

/DIV> |

Y450-8 |

315/6000 |

|

250ZJ-I-A80 |

980 |

708 |

114 |

391.8 |

58.1 |

/DIV> |

Y450-6 |

500/6000 |

|

1175 |

110.2 |

511.1 |

71 |

5.4 |

Y450-6 |

630/6000 |

|

1416 |

106.7 |

566.7 |

74.6 |

/DIV> |

Y500-6 |

710/6000 |

|

730 |

527 |

63.2 |

161.7 |

56.1 |

/DIV> |

Y400-8 |

200/6000 |

|

875 |

61.1 |

211 |

69 |

3.4 |

Y400-8 |

280/6000 |

|

1054 |

59.2 |

234.1 |

72.6 |

/DIV> |

Y400-8 |

280/6000 |

|

250ZJ-I-78 |

980 |

690 |

108.4 |

376.5 |

56.1 |

/DIV> |

Y450-6 |

450/6000 |

|

1145 |

104.8 |

487.7 |

69 |

5.1 |

Y450-6 |

630/6000 |

|

1380 |

101.4 |

539.8 |

72.6 |

/DIV> |

Y450-6 |

630/6000 |

|

730 |

514 |

60.1 |

155.5 |

54.1 |

/DIV> |

Y355L1-8 |

185/6000 |

|

853 |

58.1 |

201.4 |

67 |

3.2 |

Y400-8 |

250/6000 |

|

1028 |

56.3 |

223.3 |

70.6 |

/DIV> |

Y400-8 |

280/6000 |

|

250ZJ-I-A75 |

980 |

600 |

97.5 |

255.7 |

62.3 |

/DIV> |

Y400-6 |

315/6000 |

|

1100 |

92 |

362.6 |

76 |

4.1 |

Y450-6 |

450/6000 |

|

1480 |

83.2 |

443.6 |

75.6 |

/DIV> |

Y450-6 |

560/6000 |

|

730 |

447 |

54.1 |

105.7 |

62.3 |

/DIV> |

Y355M1-8 |

132/6000 |

|

819 |

51 |

149.7 |

76 |

3 |

Y355L1-8 |

185/6000 |

|

1102 |

46.2 |

183.4 |

75.6 |

/DIV> |

Y400-8 |

220/6000 |

|

250ZJ-I-A73 |

980 |

584 |

92.4 |

239.7 |

61.3 |

/DIV> |

Y400-6 |

280/6000 |

|

1071 |

87.2 |

339.1 |

75 |

4.1 |

Y400-6 |

400/6000 |

|

1441 |

78.8 |

414.5 |

74.6 |

/DIV> |

Y450-6 |

500/6000 |

|

730 |

435 |

51.3 |

99.1 |

61.3 |

/DIV> |

Y355M1-8 |

132/380 |

|

797 |

48.3 |

139.8 |

75 |

3 |

Y355L1-8 |

185/6000 |

|

1073 |

43.8 |

171.6 |

74.6 |

/DIV> |

Y355L2-8 |

200/380 |

|

250ZJ-I-A70 |

980 |

560 |

84.9 |

218.3 |

59.3 |

/DIV> |

Y400-6 |

280/6000 |

|

1027 |

80.1 |

306.9 |

73 |

3.9 |

Y400-6 |

400/6000 |

|

1381 |

72.5 |

375.6 |

72.6 |

/DIV> |

Y450-6 |

450/6000 |

|

730 |

417 |

47.1 |

90.2 |

59.3 |

/DIV> |

Y315L2-8 |

110/380 |

|

764 |

44.4 |

126.5 |

73 |

2.9 |

Y355M2-8 |

160/380 |

|

1029 |

40.2 |

155.2 |

72.6 |

/DIV> |

Y355L1-8 |

185/380 |

|

250ZJ-I-A68 |

980 |

544 |

80.1 |

203.5 |

58.3 |

/DIV> |

Y355-6 |

250/6000 |

|

997 |

75.6 |

285.1 |

72 |

3.7 |

Y400-6 |

355/6000 |

|

1342 |

68.4 |

349.1 |

71.6 |

/DIV> |

Y450-6 |

450/6000 |

|

730 |

405 |

44.5 |

84.2 |

58.3 |

/DIV> |

Y315L2-8 |

110/380 |

|

743 |

41.9 |

117.8 |

72 |

2.7 |

Y355M2-8 |

160/380 |

|

999 |

38 |

144.4 |

71.6 |

/DIV> |

Y355L1-8 |

185/380 |

|