|

FSP(R) Series Pumps

Products overview

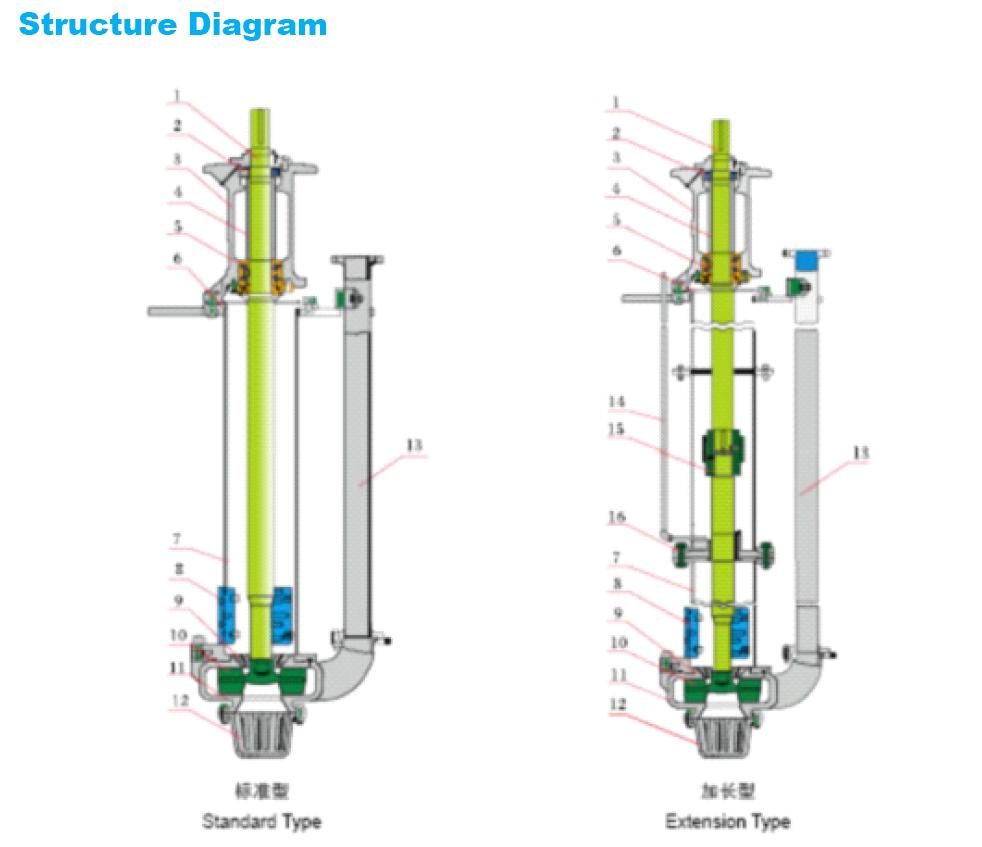

FSP(R) series pumps are vertical, centrifugal slurry pumps submerged in liquid to work. They are designed for delivering abrasive, large particle and high density slurries, and require no shaft seal and sealing water. They can also be operated normally even under insufficient suction duties conditions. Overflow parts of FSP pumps are made of abrasion-resistant metal. All parts of type FSPR pump immersed in liquid are lined with rubber outer liner. They are suited to transport non-edge angle abrasive slurry. The type No. with "L" is a submerged pump of extended shaft series, which is suited for the working condition of deeper level. The guide bearing construction is added to the pump on the basis of the standard pump, so the pump runs steadier and more application range used, but flushing water should be attached to the guide bearing.

Meaning of the type

65QV(L)-FSPR

65: Pump outlet diameter(mm)

QV: Bracket form

L: Shaft lengthened

FSP: Sump pump

FSPR: Rubber lining sump pump

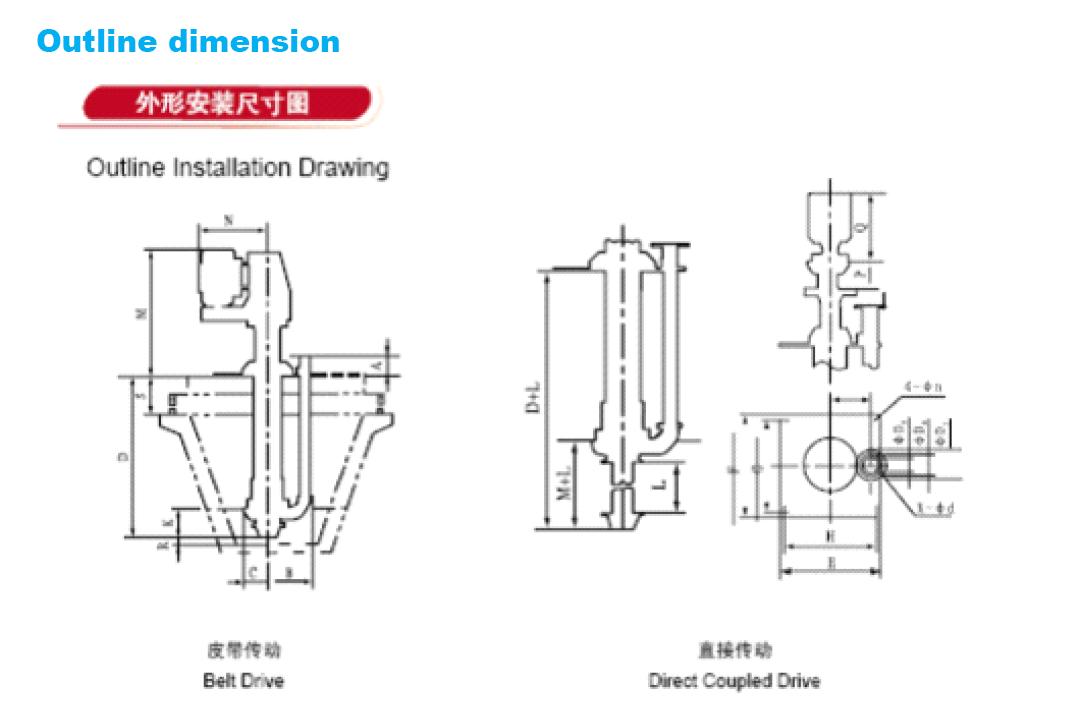

Outline dimension

|

Pump |

A |

B |

C |

D |

E |

F |

G |

H |

|

Outlet diameter |

Bracket |

Type |

Standard type |

Extended type |

|

40 |

PV(L�?/DIV> |

SP |

137 |

285 |

153 |

900* |

1800* 2000 2500 |

500 |

500 |

450 |

450 |

|

SPR |

140 |

265 |

175 |

1200 |

|

J |

Φn |

K |

M |

N |

P |

Q |

Pump weight kg |

S |

Outlet flange dimensions |

|

Note: the size of the motor to change as shown in the table size is the maximum size |

ΦD1 |

ΦD2 |

ΦD0 |

×-Φd |

|

205 |

18 |

174 |

1113 |

675 |

248 |

629 |

285 |

280 |

127 |

40 |

98 |

4-Φ16 |

|

1113 |

/DIV> |

Technical parameters

|

Type |

allo with maximum power |

material |

Water properties |

Impeller |

|

sheath |

impeller |

flow Q |

Lift H |

Rotational speed(n) |

Max efficiency |

NPSH |

left number |

Diameter |

|

�?/B>m³/h) |

�?/B>l/s�?/B> |

(m) |

(r/min) |

(%) |

|

40PV(L)-FSP |

15 |

M |

M |

19.44~43.2 |

5.4~12 |

4.5~28.5 |

1000~2200 |

40 |

5 |

188 |

|

40PV(L)-FSPR |

RU |

RU |

17.28~39.6 |

4.8~11 |

4~26 |

1000~2200 |

40 |

5 |

188 |

|

65QV(L)-FSP |

30 |

M |

M |

23.4~111 |

6.5~30.8 |

5~29.5 |

700~1500 |

50 |

5 |

280 |

|

65QV(L)-FSPR |

RU |

RU |

22.5~105 |

6.25~29.15 |

5.5~30.5 |

700~1500 |

51 |

5 |

280 |

|

100RV(L)-FSP |

75 |

M |

M |

54~289 |

15~80.3 |

5~35 |

500~1200 |

56 |

5 |

370 |

|

100RV(L)-FSPR |

RU |

RU |

64.8~285 |

18~79.2 |

7.5~36 |

600~1200 |

62 |

5 |

370 |

|

150SV(L)-FSP |

110 |

M |

M |

108~479.16 |

30~133.1 |

8.5~40 |

500~1000 |

52 |

5 |

450 |

|

200SV(L)-FSP |

110 |

M |

M |

189~891 |

152.5~247.5 |

6.5~37 |

400~850 |

64 |

5 |

520 |

|

250TV(L)-FSP |

200 |

M |

M |

261~1089 |

72.5~302.5 |

7.5~33.5 |

400~750 |

60 |

5 |

575 |

|

300TV(L)-FSP |

200 |

M |

M |

288~1267 |

80~352 |

6.5~33 |

350~700 |

50 |

5 |

610 |

Note: the" M" represents metal wear-resistant materials, "RU" stands for rubber materials.

|