|

FAH, FHH Series Slurry Pump

Main technical parameters

Caliber: DN25-DN400mm

Flow: 12-5040m3/hr Head: 5-118 m

Rotate speed: 300-3800r/min

Motor power: 15-1200 KW

Working temperature: ’┐Į?0 ┬░C

Product overview

FAH, FHH type pump is a cantilever horizontal centrifugal slurry pump. It is applied to transport high abrasion, high concentration slurry in metallurgy, mining, coal, power, building materials and other industrial sectors. This type can also use multi-level series.

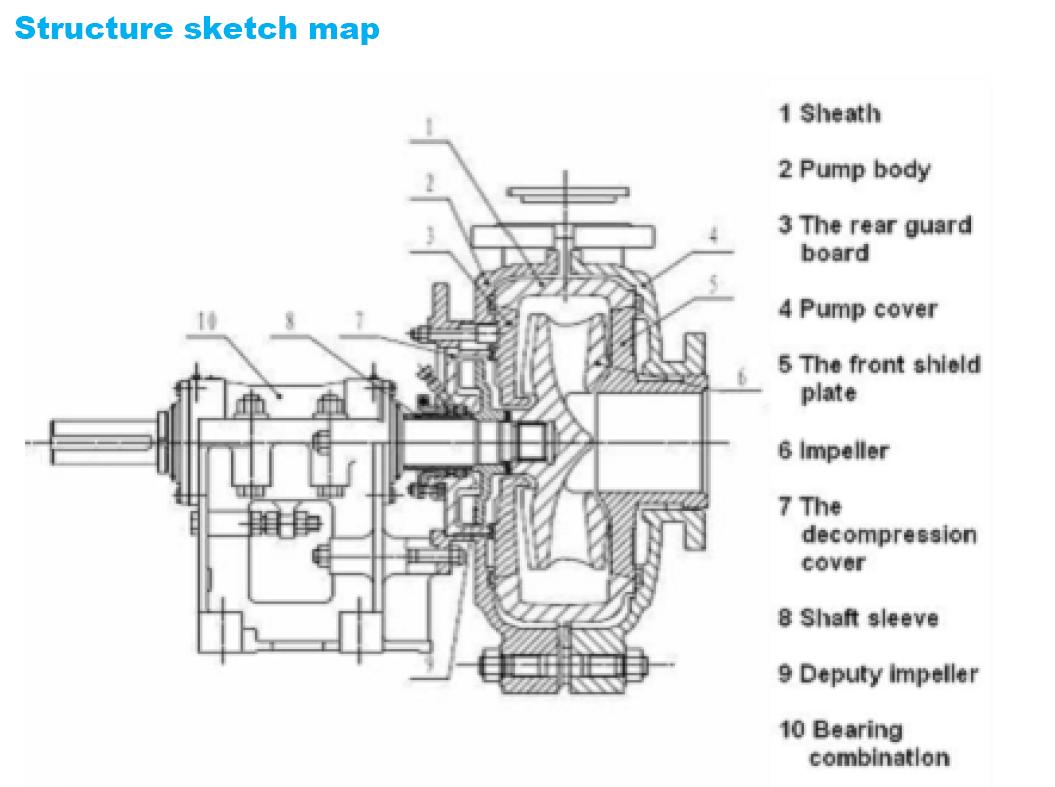

FAH type pump body has a replaceable wear-resistant metal liner or rubber liner and Wear-resistant metal or rubber impellers. FHH type pump bodyŌĆÖs liner and impeller adopts wear-resistant metal.FAH, FHH type pump shaft seal can adopt packing seal or centrifugal seal. Pump outlet location can rotate eight different installation angle by at interval of 45 DEG.

Product features

This slurry pump is a horizontal, double pump shell, metal liner pump body and pump cover.

The liner can be used until worn out, which extends repair period and reduce running cost.

The slurry pump outlet direction can be according to the eight rotation angle mounting.

The slurry pump bearing assembly use circular cylinder structure, which is convenient to adjust the space between impeller and front plate. It can be overall open out when repair.

The slurry pump shaft seal type can use the packing seal, vice impeller seal, mechanical seal.

The series slurry pumps possess wide performance range, good cavitation performance,

high efficiency. It can take the multistage tandem technology to meet the long-distance

transport.

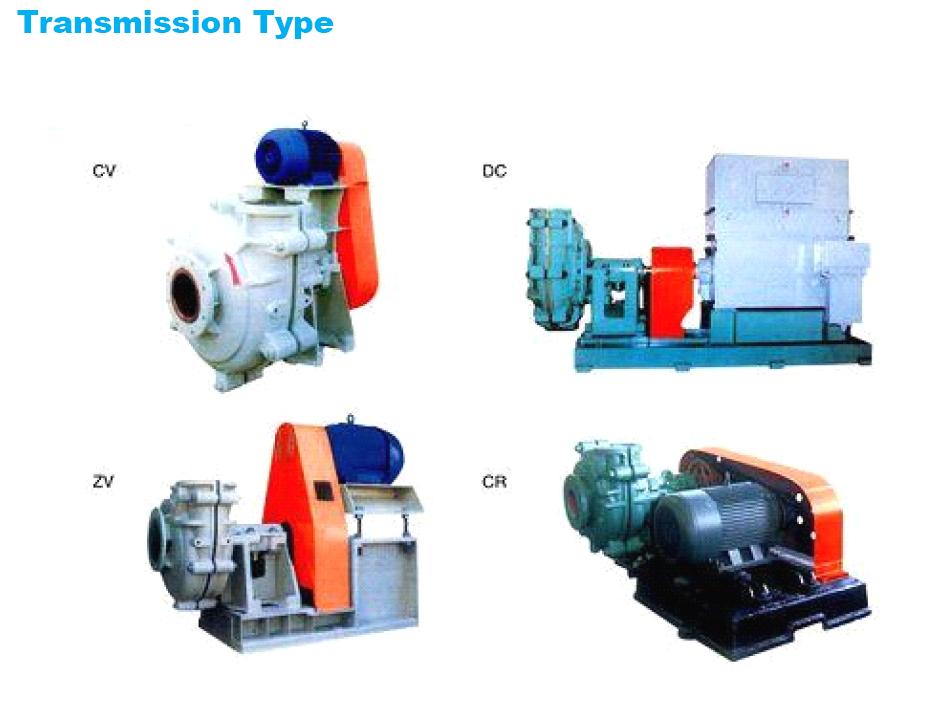

The transmission way has V type of triangle belt transmission, the elastic shaft coupling drive, gear drive, hydraulic coupling transmission, variable frequency drive, SCR adjusting speed. The V type belt transmission has CL, CV, CR, ZL, ZV, ZR transmission.

Various flow components metal materials are available.

Make sure operating in optimal mining by use of a variety of speed and multiple variant .

Long service life, high efficiency satisfy many kinds of poor transportation conditions.

Main application

The slurry pumps are mainly applied to the transmission of strongly corrosive, high

concentration slurry or low concentration, low corrosion and high lift slurry, such as coal preparation process, power station hydraulic ash disposal system, blast furnace slag, colored, black mine, chemical mine. It is the ideal pump for slurry transport.

Meaning of the type

FAH(FHH)10ST

FAH or FHH: slurry pump type

10: Pump outlet diameter(inch)

ST: Bracket form

Technical parameters

|

Type |

allo with maximum power |

material |

Water properties |

Impeller |

|

sheath |

impeller |

flow Q |

Lift H |

Rotational speed(n) |

Max efficiency |

NPSH |

left number |

Diameter |

|

ŃĆĆ/DIV> |

ŃĆĆ/DIV> |

’╝łm³/h) |

’╝łl/s’┐Į?/DIV> |

(m) |

(r/min) |

(%) |

(m) |

|

FAH1.5B |

15 |

M |

M |

12.6~28.8 |

3.5~8 |

6~68 |

1200~3800 |

40 |

2~4 |

5 |

152 |

|

RU |

RU |

10.8~25.2 |

3~7 |

7~52 |

1400~3400 |

35 |

3 |

|

FHH 1.5C |

30 |

M |

M |

16.2~34.2 |

4.5~9.5 |

25~92 |

1400~2200 |

20 |

2~5.5 |

5 |

330 |

|

FAH2B |

15 |

M |

M |

32.4~72 |

9~20 |

6~58 |

1200~3200 |

45 |

3.5~8 |

5 |

184 |

|

RU |

RU |

25.2~54 |

7~15 |

5.5~41 |

1000~2600 |

50 |

2.5~5 |

178 |

|

FAH3C |

30 |

M |

M |

38.6~86.4 |

11~24 |

12~64 |

1300~2700 |

55 |

4~6 |

5 |

214 |

|

RU |

RU |

36~75.6 |

10~21 |

13~46 |

1300~2300 |

60 |

2~4 |

213 |

|

FHH 3D |

60 |

M |

M |

68.4~136.8 |

19~38 |

25~87 |

850~1400 |

47 |

3~7.5 |

5 |

457 |

|

FAH4C |

30 |

M |

M |

86.4~198 |

24~55 |

9~52 |

1000~2200 |

71 |

4~6 |

5 |

245 |

|

RU |

RU |

79.2~180 |

22~50 |

5~34.5 |

800~1800 |

59 |

3~5 |

|

FHH 4E |

120 |

M |

M |

126~252 |

35~70 |

12~97 |

600~1400 |

50 |

2~5 |

5 |

508 |

|

FAH6D |

60 |

M |

M |

162~360 |

40~100 |

12~56 |

800~1550 |

65 |

5~8 |

5 |

365 |

|

RU |

RU |

144~324 |

40~90 |

12~45 |

800~1350 |

65 |

3~5 |

|

FHH 6S |

560 |

M |

M |

324~720 |

90~200 |

30~118 |

600~1000 |

64 |

3~8 |

5 |

711 |

|

FHH 6S |

560 |

M |

M |

468~1008 |

130~280 |

20~94 |

500~1000 |

65 |

4~12 |

5 |

711 |

|

FAH8R |

300 |

M |

M |

360~828 |

100~230 |

10~61 |

500~1140 |

72 |

2~9 |

5 |

510 |

|

RU |

RU |

324~720 |

90~200 |

7~49 |

400~1000 |

65 |

5~10 |

|

FAH10E |

120 |

M |

M |

666~1440 |

185~400 |

14~60 |

600~1100 |

73 |

4~10 |

5 |

549 |

|

FAH10ST |

560 |

M |

M |

612~1368 |

170~380 |

11~61 |

400~850 |

71 |

4~10 |

5 |

686 |

|

RU |

RU |

540~1188 |

150~330 |

12~50 |

400~750 |

75 |

4~12 |

|

FAH12ST |

560 |

M |

M |

936~1980 |

260~550 |

7~68 |

300~800 |

82 |

6 |

5 |

762 |

|

RU |

RU |

720~1620 |

200~450 |

7~45 |

300~650 |

80 |

2.5~7.5 |

|

FAH14ST |

560 |

M |

M |

1260~2772 |

350~770 |

13~63 |

300~600 |

77 |

3~10 |

5 |

965 |

|

RU |

RU |

1152~2520 |

320~700 |

13~44 |

300~500 |

79 |

3~8 |

|

FAH16TU |

1200 |

M |

M |

1368~3060 |

380~850 |

11~63 |

250~550 |

79 |

4~10 |

5 |

1067 |

|

FAH20TU |

1200 |

M |

M |

2520~5400 |

700~150 |

13~57 |

200~400 |

85 |

5~10 |

5 |

1370 |

Note:

1. TheŌĆØM’┐Į?represents metal wear-resistant material;ŌĆØRU’┐Į?stands for rubber materials.

2. Recommended range of flow 5QŌĆØQ’┐Į?(Q=110Q corresponding to the maximum efficiency point flow).

3. NPSH refers to the maximum speed; recommend Q dot corresponding NPSH value

|

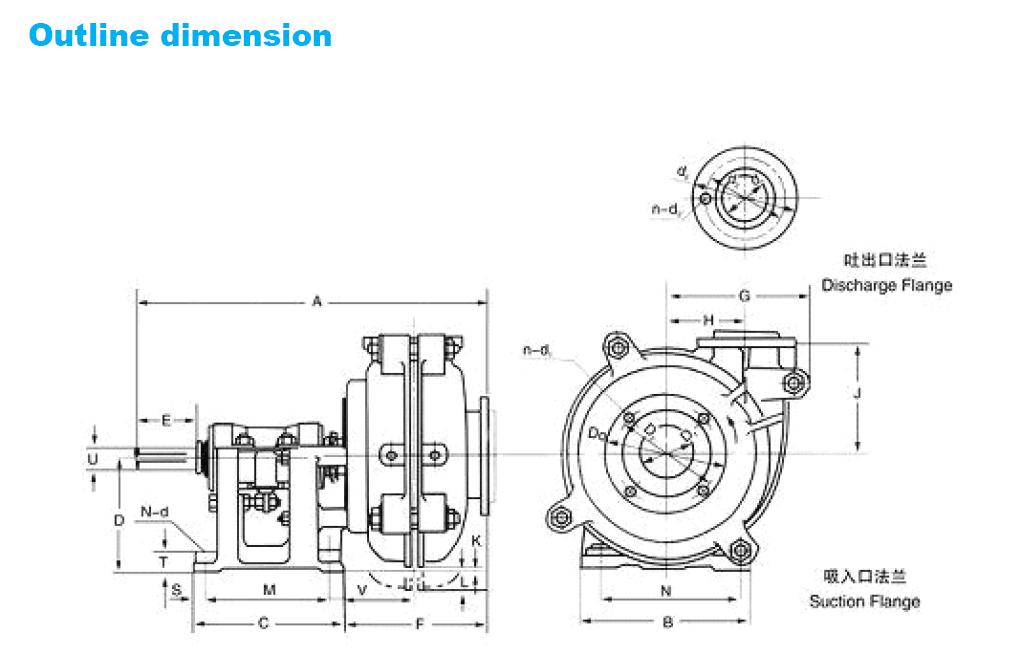

Type |

A |

B |

C |

D |

U |

E |

F |

G |

H |

J |

K |

L |

M |

N |

V |

|

FAH1.5B |

583 |

295 |

248 |

197 |

28 |

79 |

206 |

181 |

98 |

171 |

46 |

- |

143 |

254 |

181 |

|

FHH1.5C |

759 |

406 |

311 |

254 |

42 |

121 |

306 |

270 |

194 |

254 |

- |

11 |

175 |

356 |

252 |

|

FAH2B |

592 |

295 |

428 |

197 |

28 |

79 |

217 |

205 |

114 |

184 |

33 |

- |

143 |

254 |

184 |

|

FAH3C |

768 |

406 |

311 |

254 |

42 |

121 |

281 |

238 |

138 |

210 |

71 |

- |

175 |

356 |

233 |

|

FHH3D |

986 |

492 |

364 |

330 |

65 |

164 |

389 |

384 |

254 |

368 |

- |

51 |

213 |

432 |

298 |

|

FAH4C |

843 |

406 |

311 |

254 |

42 |

121 |

354 |

292 |

149 |

262 |

24 |

- |

185 |

356 |

270 |

|

FAH4D |

943 |

492 |

364 |

330 |

65 |

164 |

353 |

292 |

149 |

262 |

100 |

- |

213 |

432 |

279 |

|

FHH4E |

1240 |

622 |

448 |

457 |

80 |

222 |

492 |

492 |

330 |

432 |

- |

- |

257 |

546 |

381 |

|

FAH6D |

1021 |

492 |

364 |

330 |

65 |

164 |

421 |

406 |

229 |

338 |

11 |

- |

213 |

432 |

318 |

|

FAH6E |

1178 |

622 |

448 |

457 |

80 |

222 |

433 |

406 |

229 |

338 |

138 |

- |

257 |

546 |

351 |

|

FHH 6S |

1668 |

920 |

780 |

450 |

120 |

280 |

296 |

616 |

413 |

546 |

- |

134 |

640 |

760 |

353 |

|

FAH8E |

1302 |

622 |

448 |

457 |

80 |

222 |

557 |

551 |

318 |

460 |

- |

62 |

257 |

546 |

402 |

|

FAH8R |

1360 |

680 |

590 |

350 |

85 |

215 |

- |

511 |

318 |

460 |

- |

170 |

490 |

560 |

312 |

|

FHH 8T |

2275 |

1150 |

1040 |

650 |

150 |

350 |

852 |

835 |

584 |

813 |

- |

160 |

880 |

900 |

538 |

|

FAH10E |

1337 |

622 |

448 |

457 |

80 |

222 |

584 |

613 |

384 |

470 |

- |

83 |

257 |

546 |

403 |

|

FAH10R |

1395 |

680 |

590 |

350 |

85 |

215 |

- |

613 |

384 |

470 |

- |

190 |

490 |

560 |

314 |

|

FAH10ST |

1748 |

1150 |

780 |

650 |

120 |

280 |

692 |

673 |

419 |

635 |

27 |

- |

620 |

900 |

439 |

|

FAH12ST |

1816 |

1150 |

780 |

650 |

120 |

280 |

762 |

775 |

464 |

674 |

- |

65 |

620 |

900 |

461 |

|

FAH14ST |

1873 |

1150 |

780 |

650 |

120 |

280 |

712 |

937 |

629 |

832 |

- |

224 |

620 |

900 |

486 |

|

FAH16TU |

2320 |

1460 |

1050 |

900 |

150 |

350 |

953 |

1048 |

660 |

889 |

- |

84 |

860 |

1200 |

597 |

|

FAH20TU |

2475 |

1460 |

1050 |

900 |

150 |

350 |

1100 |

1420 |

940 |

1230 |

- |

420 |

860 |

1200 |

615 |

|

FHH 6S |

1700 |

920 |

785 |

450 |

120 |

280 |

622 |

625 |

415 |

615 |

- |

155 |

640 |

760 |

382 |

|

Type |

T |

S |

n-d |

Inlet |

Outlet flange |

Pump weight |

|

D0 |

D1 |

D2 |

n-d1 |

d0 |

d1 |

d2 |

n-d2 |

Metal |

Rubber |

|

FAH1.5B |

38 |

24 |

4-Žå14 |

152 |

38 |

114 |

4-Žå16 |

165 |

25 |

127 |

4-Žå16 |

91 |

77 |

|

FHH1.5C |

48 |

32 |

4-Žå19 |

152 |

38 |

114 |

4-Žå17 |

152 |

25 |

114 |

4-Žå17 |

318 |

’┐Į?/DIV> |

|

FAH2B |

38 |

24 |

4-Žå14 |

184 |

51 |

146 |

4-Žå19 |

165 |

38 |

127 |

4-Žå19 |

104 |

118 |

|

FAH3C |

48 |

32 |

4-Žå19 |

216 |

76 |

178 |

4-Žå19 |

184 |

51 |

146 |

4-Žå19 |

191 |

154 |

|

FHH3D |

64 |

38 |

4-Žå22 |

216 |

76 |

178 |

4-Žå19 |

203 |

51 |

165 |

4-Žå19 |

750 |

’┐Į?/DIV> |

|

FAH4C |

48 |

32 |

4-Žå19 |

279 |

102 |

235 |

4-Žå22 |

229 |

76 |

191 |

4-Žå22 |

263 |

236 |

|

FAH4D |

64 |

38 |

4-Žå22 |

279 |

102 |

235 |

4-Žå22 |

229 |

76 |

191 |

4-Žå22 | ,

363 |

290 |

|

FHH4E |

76 |

54 |

4-Žå29 |

254 |

,

102 |

210 |

4-Žå19 |

254 |

76 |

210 |

4-Žå19 |

1250 |

’┐Į?/DIV> |

|

FAH6D |

64 |

38 |

4-Žå22 |

337 |

152 |

292 |

4-Žå22 |

279 |

102 |

235 |

4-Žå22 |

626 |

454 |

|

FAH6E |

76 |

54 |

4-Žå29 |

337 |

152 |

292 |

4-Žå22 |

279 |

102 |

235 |

4-Žå22 |

728 |

635 |

|

FHH6S |

90 |

70 |

4-Žå35 |

337 |

152 |

292 |

4-Žå22 |

205 |

120 |

260 |

4-Žå22 |

2880 |

’┐Į?/DIV> |

|

FAH8E |

76 |

54 |

4-Žå29 |

406 |

203 |

356 |

4-Žå22 |

268 |

152 |

321 |

4-Žå21 |

1473 |

982 |

|

FAH8R |

70 |

50 |

4-Žå28 |

406 |

203 |

356 |

4-Žå22 |

368 |

152 |

321 |

4-Žå22 |

1655 |

’┐Į?/DIV> |

|

FHH8T |

125 |

80 |

4-Žå48 |

432 |

203 |

375 |

4-Žå29 |

432 |

152 |

375 |

4-Žå29 |

6586 |

’┐Į?/DIV> |

|

FAH10E |

76 |

54 |

4-Žå29 |

502 |

254 |

445 |

4-Žå29 |

432 |

203 |

375 |

4-Žå29 |

1625 |

1202 |

|

FAH10R |

70 |

50 |

4-Žå28 |

502 |

254 |

445 |

4-Žå29 |

432 |

203 |

375 |

4-Žå29 |

1836 |

’┐Į?/DIV> |

|

FAH10ST |

125 |

80 |

4-Žå48 |

502 |

254 |

445 |

4-Žå29 |

432 |

203 |

375 |

4-Žå29 |

3750 |

3130 |

|

FAH12ST |

125 |

80 |

4-Žå48 |

527 |

305 |

470 |

4-Žå25 |

527 |

254 |

470 |

4-Žå25 |

4318 |

3357 |

|

FAH14ST |

125 |

80 |

4-Žå48 |

585 |

356 |

521 |

4-Žå25 |

552 |

305 |

495 |

4-Žå25 |

6409 |

4672 |

|

FAH16TU |

150 |

95 |

4-Žå79 |

705 |

406 |

341 |

4-Žå35 |

673 |

356 |

610 |

4-Žå29 |

10000 |

’┐Į?/DIV> |

|

FAH20TU |

150 |

95 |

4-Žå79 |

900 |

508 |

800 |

4-Žå42 |

900 |

460 |

800 |

4-Žå42 |

18864 |

15921 |

|

FHH6S |

90 |

70 |

4-Žå35 |

380 |

152 |

320 |

4-Žå27 |

420 |

150 |

360 |

4-Žå27 |

’┐Į?/DIV> |

’┐Į?/DIV> |

|