|

XG’S basic introduction about development process, mechanical and chemical testing system of heavy plate

Dear Sir,

As one of our main business is to hand pick the Top 5 producers in its related field to be our sub contractors or consortium members, we are now cooperating with China’s top 2 heavy alloy steel plate producer of XZ steel mill to supply high end heavy alloy plates to the power industry, oil exploration, oil/gas production, marine platform, heavy equipments, structural steel plate for high buildings, bridges.

We have reached agreement with XG that they will support us with best technical and commercial terms.

We are looking for agents/dealer/users to work with us for the world level heavy alloy plate business in the world. if interested, please contact:

Yangchunlin

Leda Greenpower/CEO

Tel: 0086 13801218512

Beijing, China.

Attached: Heavy Plate Introduction.

CONTENTS

1. Development of heavy plate

2. Process of plate

3. Equipment, production capability & Testing system

4. Plate for pressure vessel

5. Tube & Wire rod

XG’s Heavy Alloy Steel Plate Supply Reference

|

Year |

Material specification |

Dimensions |

QTY |

Customer |

|

(mm) |

(MT) |

|

Jul. 2011 |

SA387Gr11CL2 |

144*4670*4670 |

130 |

Dalian Jinzhong, CN |

|

Sep. 2011 |

Q245R |

230*2300*6100 |

75 |

Zhongli Steel, CN |

|

Nov. 2011 |

Q345R |

138*4780*4780 |

286 |

Dalian Jinzhong, CN |

|

Dec. 2012 |

07MnCrMoVR-Z35 |

124*2050*6590 |

53 |

Jinheng Co, Ltd. |

|

Dec. 2012 |

Q345R |

160*3100*6200 |

93 |

Xiangdong MM CO. |

|

Jan. 2011 |

SA516Gr.70 |

112*4360*4360 |

134 |

Sinopec, CN |

|

Feb, 2012 |

SA516Gr.70 |

87*4300*4300 |

101 |

Dalian Jinzhong, CN |

|

Feb, 2012 |

13MnNiMo5-4 |

90*3220*6700 |

157 |

Wuxi Boiler |

|

Mar. 2011 |

SA299Gr.A |

110*2980*5952 |

145 |

Wuxi Boiler |

|

Mar. 2011 |

A516Gr.70 |

150*2000*10000 |

116 |

Huarui heavy Industry |

|

Mar. 2011 |

Q345R |

138*4780*4780 |

143 |

Dalian Jinzhong, CN |

|

Apr. 2012 |

SA387Gr22CL2 |

135*2250*4700 |

167 |

JinchengOil Mechanics |

|

Apr. 2012 |

SA387Gr11CL2 |

175*2200*6400 |

97 |

Ruiye Enterprise |

|

Apr. 2012 |

12Cr2Mo1RZ35 |

130*3750*3750 |

72 |

Huarui heavy Industry |

|

Apr. 2012 |

Q245R-Z25 |

180*2300*8000 |

156 |

Shenxin, Shanghai |

|

May. 2012 |

14Cr1MoR |

108*3300*3300 |

54 |

Dalian Jinzhong, CN |

|

May. 2011 |

SA299Gr.A |

178*3220*8640 |

78 |

Harbin Boiler Factory |

|

May. 2012 |

13MnNiMo5-4 |

145*3600*7500 |

62 |

Harbin Boiler Factory |

|

Jun. 2012 |

Q345R |

101*4600*4600 |

134 |

Tianli Xi'an |

|

Jun. 2011 |

Q345R |

105*4100*4150 |

112 |

Jinglei, CN |

|

Jun. 2011 |

SA387Gr11CL2 |

110*2910*8650 |

83 |

Oriental Boiler |

|

Jun. 2011 |

P355GH |

120*2520*5550 |

123 |

Oriental Boiler |

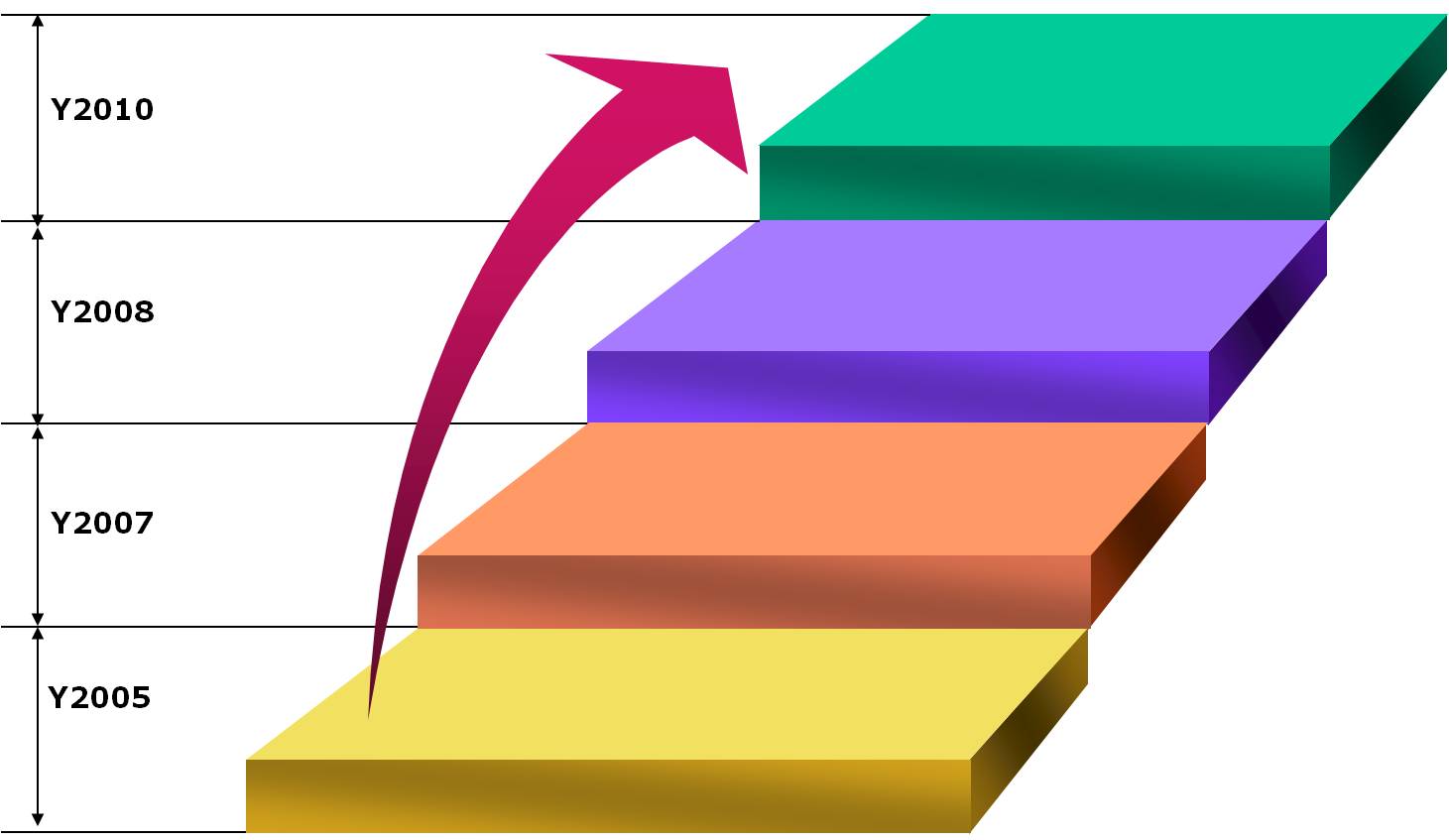

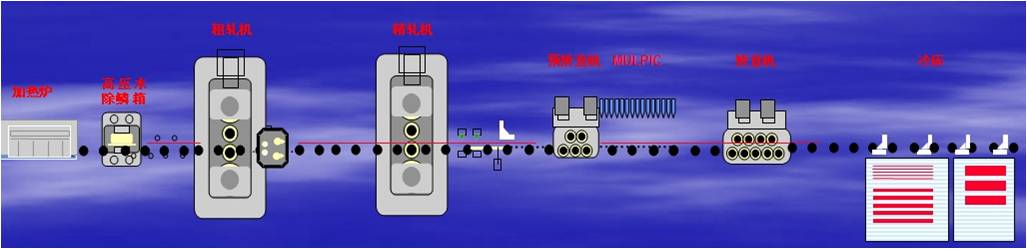

Development of heavy plate in XG

Note:

The green: Line3 for 5m heavy plate with production 2million MT. Nowadays XG's total heavy plate yearly production capability to be 5million MT.

The purple: Normalizing furnace for adjusting quality 100,000MT yearly. Normalizing & tempering 1.5M MT yearly.

The orange: Line2 for 3.8m heavy plate.. Annual production1.2 million MT.Total production counted to 3million MT.

The yellow: Line 1 for 3.8m heavy plate. Annual production1.8million MT.

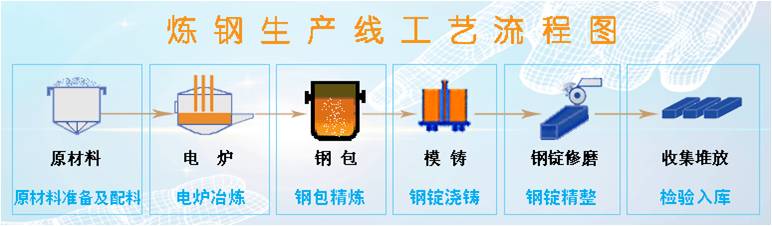

Basic information for heavy plate process

To comply with customer's various individual needs, XG manufactures pressure vessel plate from ingots & continuous cast slabs.

Ingots take advantage of high compression ratio and single weight to make super width &thickness plates with high quality.

Continuous cast slabs are produced by Voistalpine AG’s advanced equipment & technology using straight arc for multi-point bend and multi-point correction, dynamic slight pressure, gas-cool for the second cooling procedure and width adjustment on line.etc. Successfully address frustrations factors such as: central segregation of large cross-section slabs, loose and crack defect etc. All these help to improve surface quality and inside quality of plate made of slabs.

>>>>>>>>>> >>>>>>>>>> <<<<<<<<<<<<<<<< <<<<<<<<<<<<<<<<

Super heavy plate’s process

Steel making process of ingots

XG has two lines of furnace & converter in steel-making. Single weight of the heaviest ingot smelted by electric furnace is 54MT. It's enabled to produce mold ingots weighing 13.5, 20.5, 26.6,29,35,&45MT. Mold ingot cast of 54MT producible through the newest technology of water-cool process.

Metallurgical technology & equipment of converter attains 1st grade in China, producing mold ingots weighing 20.5,26.6,35&45MT.

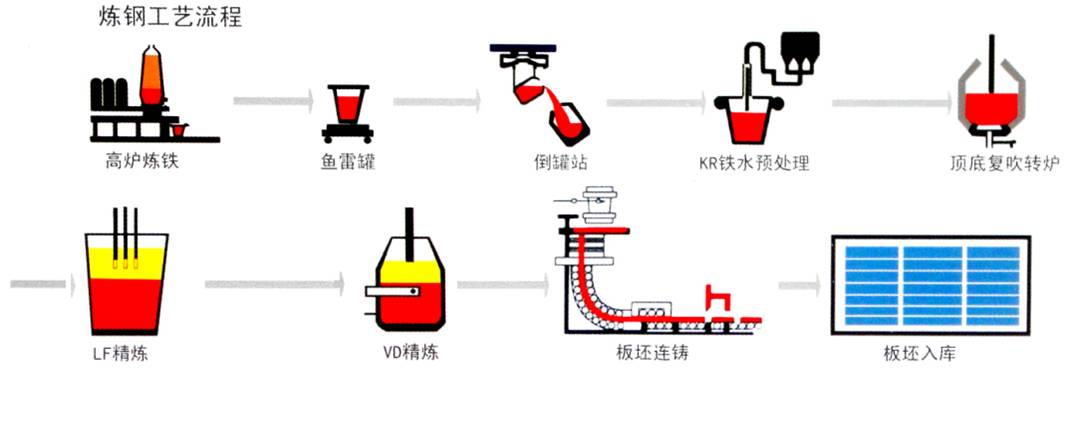

Steel making process

Continuous casting slab

4 lines of continuous casting slab enable the production to be 5million metric tons.

Rolling process

Production lin rolling flow diagram

XG has 3 lines for heavy plate, including 2lines for 3800mm width, with annual production 3 millions MT and 1 line for 5000mm width with 2 million MT designed capacity. XG aims on high-tech products and suitable for wide, thick & dedicated industrial plates. Range of dimensions: 6~350*1500~4900*6000~25000.

Introduction of equipment, capacity &testing system

Steel-making equipment & technical feature

2sets of devices for KR desulfurization (5Mmt/y)

4X120MT combined blown converters, Max. unit capacity is 150MT, 1 standby

6X120MT LF label refining furnace with max. unit cap. 150MT

2X120MT VD vacuum refining furnace with max. unit cap. 150MT

2X120t RH vacuum treating devices with max. unit cap. 165MT

4 single-flow plate casters, annually producing 5million MT.

Introduction of equipment, capacity &testing system

Rolling system & capacity

Max. Rolling force of blooming(BM) & finishing mill(FM) to be 10,000MT. Max. Opening degree of 5M BM to be 1100MM, rolling ingot with max thickness 1000MM.

Vertical roll configured at the exit of BM with max. Rolling force 800MT.

Opening degree of BM rarely seen in China. Single weight to be 24MT for continuous slabs and 40MT for ingots.

Introduction of equipment, capacity &testing system

Process & equipment of the 5000mm heavy plate was designed by SVAI and operated in Oct. 2010 with annual production 2 million MT, now in full operation. And the two 3800mm heavy plate lines are the most advanced mills in the world. SMS Sideman is the contractor of the on-line-controlling equipment and technology. It ensures the stable performance of plate together with precisely controlled dimensions.

XG adopts the System Management theory, and imported the most advanced equipments and technology from DANIELI, SVAI, SMS SIEMAG & SIEMENS, and besides, we use MES management system to ensure the stable performance of plate together with precisely controlled dimensions.

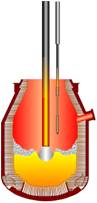

Introduction of equipment, capacity &testing system

6lines for heat treatment,designed capacity 1.3 million MT

3 normalizing lines with annual capacity of 1. 05 millions MT, configured with the longest 117M normalizing furnace in Asia.

1 quenching line with capacity of 100,000MT.

1 tempering line with annual capacity of 350,000MT.

1 car bottom furnace with annual capacity of 50,000MT.

non pressure quenching machine

(LOI of Germany)

Tempering furnace with mixed gas fire

at the bottom

(LOI, Germany)

Car bottom furnace

(WIS)

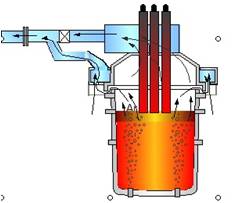

Mechanical and chemical testing system

XG’s mechanical & chemical testing centre was approved by CNAS in 2003. And reexaminated and approved in 2008.

The centre is configured by Photoelectric direct-reading spectrometer, X-fluorescence optical analyzer, Inflated carbon/sulfur analyzer, ICPspectrometer, Nitrogen/oxygen combined tester, High temperature electronic almighty tensile testing machine, Servo controlled material testing machine, Fully automatic impact testing machine with metal swing hammer, Straight-fall hammer impact testing machine, Defect projector for impacted sample, Ultrasonic testing machine.etc. And all these world level testing equipments are operated by skilled staff.

XG’s test system is an automatic, purpose-complete and precise system. We execute quick tests to molten steel, gas elements of slabs & plates and slag ingredients. We own 2 lines of spectral automated analysis system provided by Thermo Fisher , USA (modeless 2000-4460 ), 1 X-fluorescence’s spectrometer provided by Thermo Fisher (model: 9900). 2 oxygen/nitrogen/argon analyzers provided by HDRIBA(Japan), 1 carbon/sculpture analyzer provided by ELTRA(Germany, model: CS800).

ZCJ-2404 automatic impact testing machine with metal swing hammer

ZWICK-600E High temperature electronic almighty tensile testing machine

Mechanical and Chemical Testing System

And also, Test Center has direct-reading spectrometer, X-fluorescence Analyzer, Infrared Carbon/Sulfur analyzer, nitrogen-oxygen analyzers, high temperature electronic universal stretch testing machines, computer servo control material testing machine, fully automatic metal pendulum impact test Inspection machines, falling type weight impact test machine, ultrasonic flaw detection of sample gap projector, a large number of international advanced level of testing equipment and testing technicians

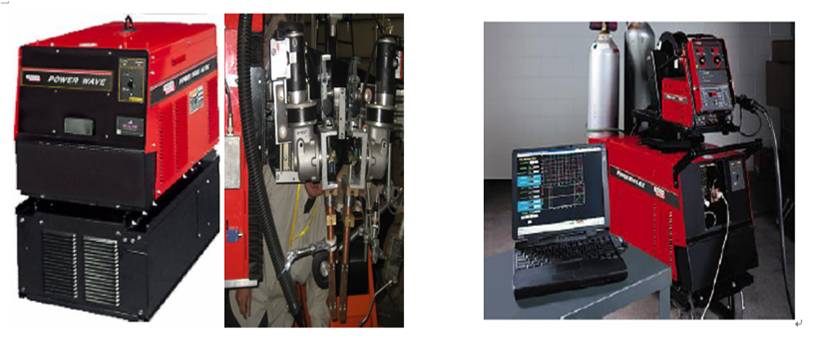

Welding lab

XG‘s welding lab is led by Ai aiguo, the national Labor Model. It carries on welding experiments according to different parameter to plates with different thickness, supplying reliable technical support to research work of new heavy plate series. It helps XG to meet specially customized needs of customers. The lab can also do welding experiments to various metal such as stainless steel, cupper , aluminum, etc.

It holds following equipments: Double wire submerged arc welder, Electro gas welder, DC arc welder, Gas-protection welder, Multifunctional tungsten Arc welding machine

|