|

146mm 12Cr2Mo1R (H) plates for petroleum chemistry

Heavy Plates with high strength, high pressure, high temperature in critical hydrogen contacting services. (Hydrogen Heavy Alloy Steel Plate)

• Due to high technical requirements of anti-corrosion & high temperature & high pressure vessels or equipments for oil/chemistry/coal chemical industry, domestic market depends on importing materials in past years from DillingerHütte GmbH and Kobe Steel Ltd., Japan.

• XG did preparation on equipments, ingredient design and process for the final production of plates for petroleum chemical industry. We focus on technology research such as smelting, casting, rolling and heat treatment and we finally succeed.

• J coefficient and vTr 54 + Δ215 vTr 54 data are indispensible indicators. Metal composition should comply with X coefficient also.

• Key technology of heavy plates for petroleum chemistry is as below:

1. Control of ingredient of P, S, Sn, Sb, As and especially P element and reasonable composition ratio design of Si and Mn .

2. All performance at 1/2 thickness of the plate be realized and well-controlled.

3. Optimized ingredient, reasonable process arrangement and realization of specific application of metallographic structure are assurance of complex mechanical properties, good weld ability and reliable performance.

Ingredient control of 130mm 12Cr2Mo1R(H)plates

|

Variety |

Heat No. |

/DIV> |

Location |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

Cu |

As |

Sn |

Sb |

[H] |

[O] |

[N] |

J |

X |

|

coefficient |

coefficient |

|

% |

ppm |

/DIV> |

/DIV> |

|

12Cr2Mo1R |

C250029 |

Heat analysis |

/DIV> |

0.12 |

0.16 |

0.34 |

0.008 |

0.0001 |

2.02 |

1.03 |

0.02 |

0.008 |

0.0096 |

0.007 |

0.0001 |

1.2 |

13 |

52 |

75 |

11.76 |

|

Component |

head |

0.12 |

0.17 |

0.36 |

0.008 |

0.0001 |

2.04 |

1.05 |

0.02 |

0.008 |

0.0096 |

0.007 |

0.0001 |

1.2 |

13 |

52 |

75 |

11.76 |

|

analysis |

end |

0.13 |

0.16 |

0.35 |

0.008 |

0.001 |

2.05 |

1.02 |

0.02 |

0.008 |

0.009 |

0.006 |

0.0001 |

1.2 |

13 |

53 |

74 |

11.75 |

Tempering embrittlement indicator Jless more and equel to 120,Calculating formola as below:

J=(Si%+Mn%)×(P%+Sn%)×104[element component%]

X=(10P+5Sb+4Sn+As)×102[el[ment component%]

• Rolling Procedures: stable and required properties in the inside and core section of the plate can be achieved through low speed, high pressure rolling mill of 10000 tons coarse and fine rolling mill so that the pressure and deformation can be reached to the inside of the plates

• Heat Treatment Procedures and management: the key factors deciding the properties of the high strength, anti corrosion, high temperature proof heavy plate in chemical and petroleum industries depend on its metallographic structure. Thanks to the high toughness, stable structure, thermal fatigue resistance properties of kainite structure, it is desirable to achieve uniformly distributed kainite structure in the whole heavy plates, and it is proven the normalizing quick cooling+tempering process can achieve ideal plates.

Mechanical performance

|

Variety |

Dimensions |

Heat treatment |

Location |

Plate |

Tensile at normal temperature |

Impact test |

|

place |

Rp0.2 |

Rm |

A |

ψ |

temperature |

impact energy |

|

12Cr2Mo1R(H) |

146mm |

Max simulation welding status |

head |

top |

477 |

594 |

26.5 |

75 |

-30°C |

310 |

305 |

308 |

|

146mm |

(690±14°C×32h ) |

under |

475 |

595 |

27.5 |

74 |

-30°C |

307 |

305 |

312 |

|

146mm |

|

1/2t |

456 |

579 |

24.9 |

65 |

-30°C |

257 |

265 |

261 |

|

146mm |

|

Diagonal at the end |

top |

480 |

601 |

26.4 |

73 |

-30°C |

305 |

308 |

302 |

|

146mm |

|

under |

474 |

593 |

26.9 |

76 |

-30°C |

312 |

308 |

300 |

|

146mm |

|

1/2t |

451 |

575 |

25.1 |

66 |

-30°C |

264 |

258 |

270 |

|

146mm |

Min simulation welding status |

head |

top |

481 |

602 |

25.7 |

71 |

-30°C |

308 |

301 |

309 |

|

146mm |

(690±×8h ) |

under |

479 |

600 |

26 |

73 |

-30°C |

305 |

312 |

310 |

|

146mm |

|

1/2t |

459 |

578 |

24.3 |

62 |

-30°C |

257 |

249 |

267 |

|

146mm |

|

Diagonal at the end |

top |

479 |

599 |

26.1 |

71 |

-30°C |

305 |

307 |

301 |

|

146mm |

|

under |

483 |

605 |

25.9 |

68 |

-30°C |

309 |

310 |

304 |

|

146mm |

|

1/2t |

460 |

579 |

24.1 |

61 |

-30°C |

249 |

251 |

256 |

• Test results indicate that all mechanic performance is great and mostly even exceed.

Mechanical performance

|

Variety |

Dimensions |

Heat treatment |

Location |

Plate |

Tensile at normal temerature |

Impact test |

|

place |

Rp0.2 |

Rm |

A |

ψ |

temperature |

impact energy |

|

12Cr2Mo1R(H) |

146mm |

Max simulation welding status |

head |

top |

477 |

594 |

26.5 |

75 |

-30°C |

310 |

305 |

308 |

|

146mm |

(690±14°C×32h ) |

under |

475 |

595 |

27.5 |

74 |

-30°C |

307 |

305 |

312 |

|

146mm |

|

1/2t |

456 |

579 |

24.9 |

65 |

-30°C |

257 |

265 |

261 |

|

146mm |

|

Diagonal at the end |

top |

480 |

601 |

26.4 |

73 |

-30°C |

305 |

308 |

302 |

|

146mm |

|

under |

474 |

593 |

26.9 |

76 |

-30°C |

312 |

308 |

300 |

|

146mm |

|

1/2t |

451 |

575 |

25.1 |

66 |

-30°C |

264 |

258 |

270 |

|

146mm |

Min simulation welding status |

head |

top |

481 |

602 |

25.7 |

71 |

-30°C |

308 |

301 |

309 |

|

146mm |

(690±×8h ) |

under |

479 |

600 |

26 |

73 |

-30°C |

305 |

312 |

310 |

|

146mm |

|

1/2t |

459 |

578 |

24.3 |

62 |

-30°C |

257 |

249 |

267 |

|

146mm |

|

Diagonal at the end |

top |

479 |

599 |

26.1 |

71 |

-30°C |

305 |

307 |

301 |

|

146mm |

|

under |

483 |

605 |

25.9 |

68 |

-30°C |

309 |

310 |

304 |

|

146mm |

|

1/2t |

460 |

579 |

24.1 |

61 |

-30°C |

249 |

251 |

256 |

|

|

|

|

|

|

|

|

|

|

|

|

|

• Test results indicate that all mechanic performances of 146mm 12Cr2Mo1R (H) plates are great and reach the standards and even exceed required data.

12Cr2Mo1R(H)cool bend & hot tensile Properties

Cool bend test result

|

Variety |

Dimensions |

Heat treatment |

Location at Width |

Location at thickness |

Cool bend=3a,180°C |

|

12Cr2Mo1R(H) |

146mm |

Delivery status |

head-mid |

surface |

qualified |

|

146mm |

end-mid |

surface |

qualified |

Tensile result at high temperature

|

Variety |

Dimension |

Heat treatment |

Temp. |

Head-angle |

End-diagonal |

|

surface |

1/4t |

1/2t |

surface |

1/4t |

1/2t |

|

Rp0.2 |

Rm |

Rp0.2 |

Rm |

Rp0.2 |

Rm |

Rp0.2 |

Rm |

Rp0.2 |

Rm |

Rp0.2 |

Rm |

|

12Cr2Mo1R(H) |

146mm |

Delivery status |

100°C |

468 |

621 |

460 |

614 |

456 |

608 |

470 |

625 |

459 |

616 |

458 |

610 |

|

146mm |

150°C |

460 |

615 |

454 |

610 |

450 |

603 |

462 |

620 |

453 |

610 |

452 |

608 |

|

146mm |

200°C |

454 |

610 |

450 |

603 |

446 |

599 |

458 |

615 |

450 |

605 |

449 |

600 |

|

146mm |

250°C |

448 |

600 |

444 |

595 |

440 |

590 |

452 |

606 |

445 |

600 |

444 |

595 |

|

146mm |

300°C |

439 |

590 |

435 |

587 |

430 |

578 |

441 |

592 |

436 |

589 |

431 |

580 |

|

146mm |

350°C |

430 |

581 |

426 |

580 |

420 |

560 |

432 |

584 |

428 |

581 |

422 |

572 |

|

146mm |

400°C |

421 |

570 |

416 |

570 |

410 |

551 |

423 |

576 |

420 |

570 |

411 |

556 |

|

146mm |

415°C |

412 |

553 |

402 |

545 |

394 |

536 |

410 |

555 |

403 |

548 |

398 |

535 |

|

146mm |

450°C |

400 |

532 |

390 |

519 |

380 |

509 |

411 |

536 |

385 |

516 |

379 |

511 |

|

146mm |

500°C |

387 |

514 |

380 |

505 |

371 |

495 |

386 |

515 |

379 |

503 |

368 |

492 |

146mm 12Cr2Mo1R (H) hardness and distribution

Surface hardness test result

|

Variety |

Dimensions |

Heat treatment |

Location |

Hardness(HB) |

|

12Cr2Mo1R(H) |

146mm |

Delivery status |

head |

201 |

205 |

203 |

206 |

202 |

|

146mm |

end |

203 |

207 |

202 |

205 |

201 |

|

146mm |

Min simulation status after welding |

head |

195 |

194 |

196 |

195 |

197 |

|

146mm |

end |

194 |

196 |

195 |

197 |

196 |

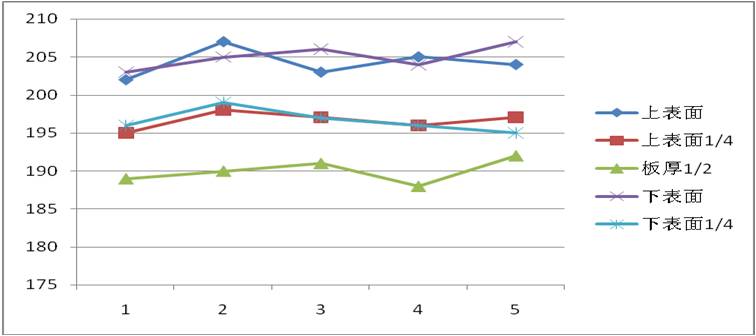

Whole thickness hardness distribution

|

Variety |

Dimension |

Heat treatment |

Location |

Hardness(HB) |

|

12Cr2Mo1R(H) |

146mm |

Delivery status |

upper surface |

202 |

207 |

203 |

205 |

204 |

|

146mm |

U/S 1/4 |

195 |

198 |

197 |

196 |

197 |

|

146mm |

1/2 |

189 |

190 |

191 |

188 |

192 |

|

146mm |

lower r surface |

203 |

205 |

206 |

204 |

207 |

|

146mm |

L/S 1/4 |

196 |

199 |

197 |

196 |

195 |

Hardness distributed at thickness-direction under delivery status

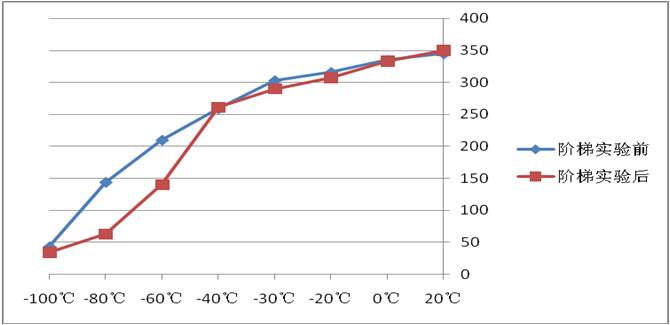

12Cr2Mo1R (H) tempera brittleness

|

Variety |

Thickness |

Heat treatment |

/B> |

Heat treatment |

/B> |

|

testing temperature |

Akv1 |

Akv2 |

Akv3 |

average |

test temp. |

Akv1 |

Akv2 |

Akv3 |

average |

|

|

|

12Cr2Mo1R(H) |

146mm |

Min simutation after welding |

20°C |

345 |

348 |

342 |

345 |

step-cooling testing status |

20°C |

348 |

352 |

350 |

350 |

|

146mm |

0°C |

342 |

329 |

334 |

335 |

0°C |

338 |

335 |

327 |

333 |

|

146mm |

-20°C |

309 |

322 |

318 |

316 |

-20°C |

296 |

309 |

315 |

307 |

|

146mm |

-30°C |

299 |

304 |

308 |

303 |

-30°C |

289 |

297 |

285 |

290 |

|

146mm |

-40°C |

266 |

254 |

257 |

259 |

-40°C |

262 |

258 |

261 |

261 |

|

146mm |

-60°C |

218 |

205 |

209 |

210 |

-60°C |

158 |

142 |

120 |

140 |

|

146mm |

-80°C |

156 |

135 |

141 |

144 |

-80°C |

65 |

55 |

71 |

63 |

|

146mm |

-100°C |

39 |

48 |

42 |

43 |

-100°C |

28 |

35 |

38 |

34 |

Conversion curvies of tempered brittleness assessed by dat, a indicated in above form

formula:vTr54 +3ΔvTr54

from the chart:vTr54=-96°C,vTr54'=-82°C.

vTr54 +3ΔvTr54=-54°C,10°C lower that the standard requirement.

12Cr2Mo1R (H) metallographic structure and nonmetallic inclusions

Metallographic structure & crystal size

|

Variety |

thickness |

location |

organization |

crystal size |

|

1/4t |

1/2t |

1/4t

|

1/2t |

|

12Cr2Mo1R(H) |

146mm |

head |

tempered kainite |

tempered kainite |

8.0 |

7.5 |

|

12Cr2Mo1R(H) |

146mm |

end |

tempered kainite |

tempered kainite |

8.0 |

7.5 |

Nonmetallic inclusions

|

Variety |

Thickness |

Location |

Place at thickness |

A type |

B type |

C type |

D type |

|

R/S |

F/S |

R/S |

F/S |

R/S |

F/S |

R/S |

F/S |

|

12Cr2Mo1R(H) |

146mm |

head |

upper surface |

0 |

0.5 |

0 |

1 |

0 |

0 |

1 |

0 |

|

146mm |

upper 1/4t |

0.5 |

0 |

0.5 |

0.5 |

0 |

0 |

0.5 |

0 |

|

146mm |

1/2t |

1 |

0 |

0 |

0.5 |

0.5 |

0 |

0 |

1 |

|

146mm |

lower 1/4t |

0 |

0.5 |

0.5 |

0 |

0.5 |

0 |

0 |

1 |

|

146mm |

lowe surface |

0.5 |

0 |

1 |

0 |

0.5 |

0.5 |

0 |

0.5 |

|

146mm |

end |

upper surface |

0 |

0 |

0.5 |

0 |

0 |

0 |

1 |

0 |

|

146mm |

upper 1/4t |

0.5 |

0 |

0.5 |

0 |

0 |

0 |

0 |

1.0 |

|

146mm |

1/2t |

0 |

0.5 |

0 |

0.5 |

0 |

0 |

1.0 |

0 |

|

146mm |

lower 1/4t |

0.5 |

0 |

0.5 |

0 |

0 |

0 |

0.5 |

0.5 |

|

146mm |

lower surface |

0 |

0.5 |

0 |

0 |

1 |

0 |

0 |

0 |

Note: R/S= Rough Series, F/S= Fine Series

12Cr2Mo1R (H) performance at thickness direction

|

Variety |

Thickness |

Heat treatment |

Width place |

Z-dirction tensile |

|

1 |

2 |

3 |

average |

|

12Cr2Mo1R(H) |

146mm |

delivery status |

head |

71 |

65 |

68 |

68 |

|

146mm |

end |

70 |

71 |

73 |

71 |

|

146mm |

max simulation status after welding

(690±14°C×32h ) |

head |

65 |

66 |

68 |

66 |

|

146mm |

end |

61 |

68 |

67 |

65 |

|

146mm |

min simulation status after welding

(690±×8h ) |

head |

72 |

63 |

69 |

68 |

|

146mm |

end |

69 |

66 |

70 |

68 |

Tensile test section area shrinkage meets 65% at the thickness direction. This indicates that the plate has strong lamellar tearing resistance capacity.

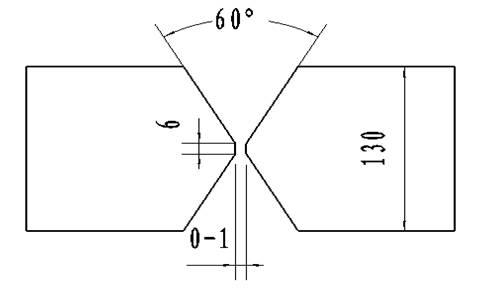

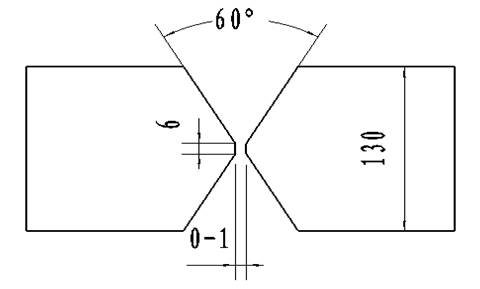

12Cr2Mo1R (H) welding process assessment

• Arc welding and submerged arc welding test, heat input of arc welding is 15KJ/cm, and 45KJ/cm for submerged arc welding.

Test plate No.2407M025100, melting composition &chemical performance of the base metal indicates in form below. Dimensions of the base metal: 1200mm (rolling direction)×225mm(width)×146mm(thickness)

Composition of base metal

|

C |

Si |

Mn |

P |

Nb |

V |

Cr |

|

0.12 |

0.16 |

0.34 |

0.008 |

0.005 |

0.004 |

2.02 |

|

Mo |

Ni |

Ti |

Sn |

As |

Ceq |

Pcm |

|

1.03 |

0.02 |

0.002 |

0.0096 |

0.007 |

0.96 |

0.31 |

Performance of base metal

|

Rel/MPa |

Rm/MPa |

A/% |

AKV (-30°C)/J |

|

Recorded |

506 |

660 |

22 |

293,303,319 |

|

Standard |

310 |

520-680 |

19 |

34 |

12Cr2Mo1R base metal hardness test

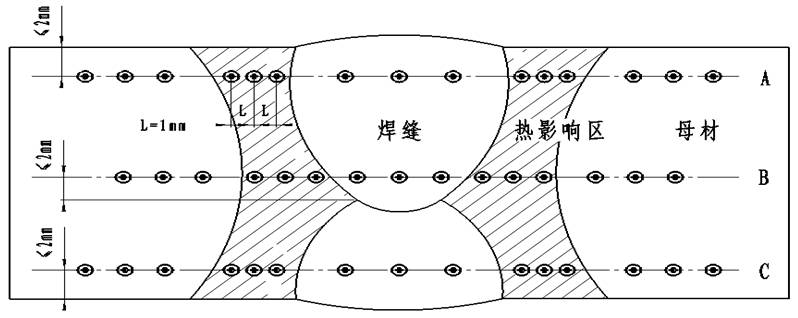

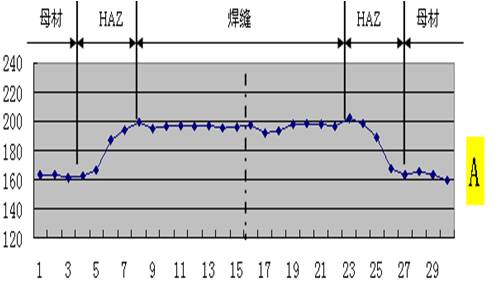

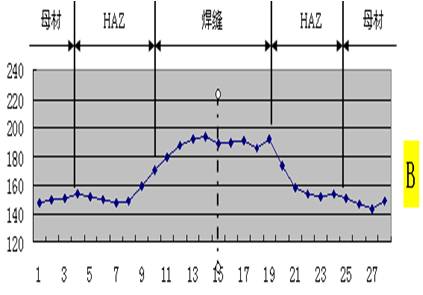

HV hardness testing point & values

|

test point |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

|

normal temp. |

263 |

260 |

257 |

269 |

274 |

267 |

268 |

270 |

323 |

325 |

290 |

292 |

281 |

282 |

270 |

266 |

268 |

|

100°C |

260 |

261 |

269 |

315 |

310 |

312 |

315 |

305 |

297 |

304 |

311 |

310 |

323 |

314 |

280 |

284 |

263 |

|

150°C |

286 |

275 |

298 |

296 |

292 |

300 |

299 |

288 |

278 |

276 |

288 |

288 |

289 |

291 |

286 |

281 |

267 |

|

200°C |

220 |

226 |

219 |

224 |

226 |

225 |

225 |

221 |

229 |

220 |

231 |

229 |

226 |

222 |

231 |

225 |

220 |

Note:Black-marked data are max. Hardness in weld affected area

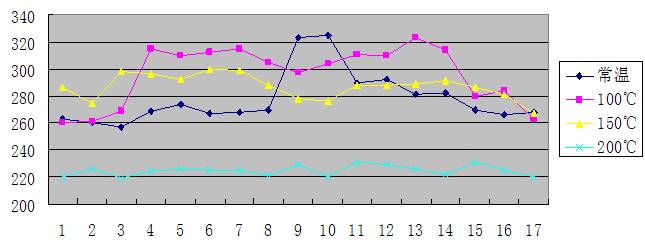

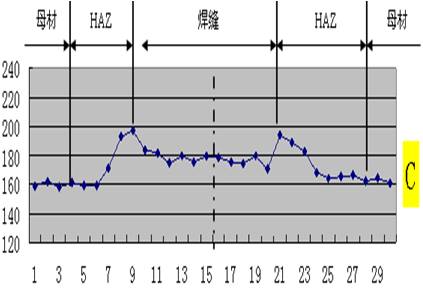

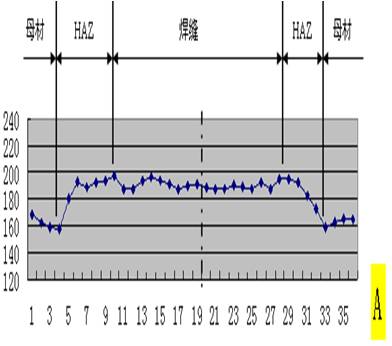

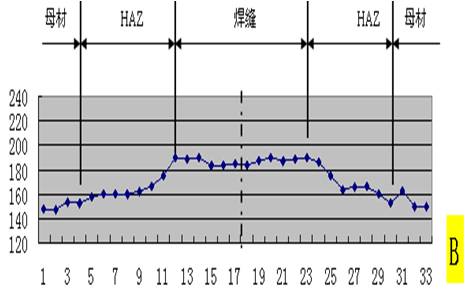

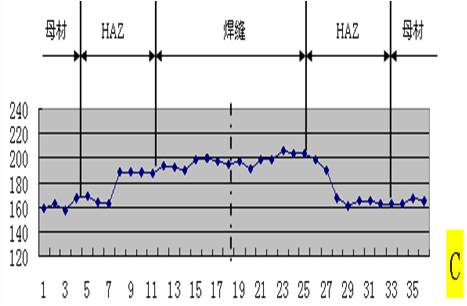

Curves of hardness values

Welding material & equipment

|

thickness |

method |

equipment |

welding material |

|

146mm |

SAW |

AC/DC1000 LIINCOLN |

Wire: CHW-S11,flux CHF101 Pacific Co. |

|

146mm |

SMAW |

DC400/ LINCOLN |

Rod:Φ3.2/4.0mm CHH307/ Pacific co. |

|

(save 1 rolling surface) |

Process parameters of different lines on energy-given-board for welding

|

board No. |

passes |

wire diameter |

Current A |

Voltage |

Speed |

Heat input KJ/cm |

|

mm |

V |

mm/s |

|

12Cr2Mo1R-11 |

1 |

Φ4.0 |

650 |

32 |

5-6 |

42 |

|

2~65 |

Φ4.0 |

700 |

33 |

5-6 |

46 |

|

average |

45 |

|

12Cr1MoVR-12 |

1 |

Φ3.2 |

110 |

25 |

|

13.4 |

|

2~12 |

Φ4.0 |

145-175 |

26-28 |

|

11.1-17.8 |

|

average |

15 |

Welding joints on the set of requirements

Result: Parts cutted from welding test board tempering in 690°C within 32 Hours & 8Hours, sample No. 12Cr2Mo1R-11-1 for 32 Hours and sample No.12Cr2Mo1R-11-2 for 8Hours. Samples remain welded.

Mechanical performance of welding joints

Tensile test for welded plate:

Tensile test samples:Matrix stretch & round stretch samples. Thickness 70mm for matrix stretch andΦ10mm bar cutted from ½ thickness of weld of the test sample. Tensile tests in normal temperature and high temperature results as follows: Tensile strength of welding joints

|

sample No. |

location |

status |

tensile strength MPa |

fracture location |

|

12Cr2Mo1R-11-1 |

welding joints |

high temperature |

530 |

weld |

|

12Cr2Mo1R-11-1 |

welding joints |

normal temperature |

540 |

weld |

|

12Cr2Mo1R-11-1 |

1/2thickness of weld |

high temperature |

550 |

|

|

12Cr2Mo1R-11-1 |

1/2thickness of weld |

normal temperature |

570 |

|

|

12Cr2Mo1R-11-2 |

welding joints |

high temperature |

550 |

weld |

|

12Cr2Mo1R-11-2 |

welding joints |

normal temperature |

570 |

weld |

|

12Cr2Mo1R-11-2 |

1/2thickness of weld |

high temperature |

580 |

|

|

12Cr2Mo1R-11-2 |

1/2thickness of weld |

normal temperature |

600 |

|

|

12Cr2Mo1R-12 |

welding joints |

normal temperature |

560,550 |

weld |

|

standard requirement |

|

|

520-680 |

|

Test result of bend and impact at weld and heat affected zone

Bending test and result:

2 side-bending sample & 2 surface-bending sampled=40mm. 180°bending angle under room temperature. No visal crack or stratification appears in sample.

Test results of impact and tempered brittleness:

Chirpy notch is used as impact sample standard. Samples are cutted from 1/2 thickness of joints exactly located at the weld center and heat affected zone. Testing temperature is -30°C. Qualified impact test results are as below:

Impact results of samples at different location

|

Sample No. |

|

|

weld center(1/2 thickness) |

HAZ 2mm(1/2t) |

|

12Cr2Mo1R-11-1 |

128 126 100 |

276 257 278 |

|

12Cr2Mo1R-11-2 |

99 96 116 |

246 257 267 |

|

12Cr2Mo1R-12 |

168 186 200 |

246 257 267 |

|

Standard |

more than and equel to 34J |

Temperature-Impact Results

|

sample No. |

temperature(°C) |

weld impact value(J) |

heat affected zone impact value(J) |

|

12Cr2Mo1R-11-1 |

Normal |

168,180,196 |

296,315,328 |

|

12Cr2Mo1R-11-1 |

0°C |

180,185,176 |

290,300,310 |

|

12Cr2Mo1R-11-1 |

-10°C |

170,178,168 |

300,285,270 |

|

12Cr2Mo1R-11-1 |

-20°C |

158,160,154 |

260,265,270 |

|

12Cr2Mo1R-11-1 |

-30°C |

130,120,110 |

255,258,260 |

|

12Cr2Mo1R-11-1 |

-40°C |

120,100,105 |

248,240,252 |

|

12Cr2Mo1R-11-1 |

-60°C |

68,60,55 |

200,210,224 |

|

12Cr2Mo1R-11-1 |

-80°C |

38,15,24 |

120,32,65 |

|

12Cr2Mo1R-11-2 |

Normal |

148,150,166 |

296,300,318 |

|

12Cr2Mo1R-11-2 |

0°C |

160,155,146 |

280,290,290 |

|

12Cr2Mo1R-11-2 |

-10°C |

150,148,138 |

280,285,260 |

|

12Cr2Mo1R-11-2 |

-20°C |

138,120,124 |

250,255,260 |

|

12Cr2Mo1R-11-2 |

-30°C |

100,90,90 |

245,238,240 |

|

12Cr2Mo1R-11-2 |

-40°C |

90,80,75 |

228,220,222 |

|

12Cr2Mo1R-11-2 |

-60°C |

58,40,45 |

160,110,124 |

|

12Cr2Mo1R-11-2 |

-80°C |

28,15,20 |

60,22,45 |

Hardness test of welding joints at different location

Testing points shows at right

12Cr2Mo1R-11 hardness distribution

Hardness distribution and ingredient of welding joints

12Cr2Mo1R-12 hardness distribution

Hardness distributed at rage of 150-200, complying to requirements

12Cr2Mo1R-11 ingrediet of welding joints (%)

|

C |

Si |

Mn |

P |

S |

Nb |

V |

Mo |

|

0.087 |

0.37 |

0.70 |

0.007 |

0.002 |

0.005 |

0.004 |

1.01 |

|

Cr |

Ni |

Ti |

Mo |

Cu |

Sn |

As |

|

|

1.94 |

0.02 |

0.002 |

1.03 |

0.01 |

0.0083 |

0.008 |

|

12Cr2Mo1R-12 ingredient of welding joints(%)(%)

|

C |

Si |

Mn |

P |

S |

Nb |

V |

Mo |

|

0.11 |

0.18 |

0.38 |

0.007 |

0.002 |

0.005 |

0.004 |

0.95 |

|

Cr |

Ni |

Ti |

Mo |

Cu |

Sn |

As |

|

|

1.92 |

0.02 |

0.002 |

1.03 |

0.11 |

0.0071 |

0.007 |

|

Testing results of welding process on 12Cr2Mo1R plate

Hard facing two samples of the plate welded by rod model L309-CHS062 produced by Atlantic Co.-till the hard face come to 3-4 mm thickness. One of the sample is welded by CHS132 again till the hard face come to 8mm thickness. Pieces cutted from the samples are tempered at 690°C 32H and 690°C 8H, testing results are as form13 below according to JB4708:

Assessment of hard facing welding process

|

projects |

standard

testing values |

remarks |

|

shear strength of fusion surface |

GB/T6396 |

300MPa |

12Cr2Mo1R-13 |

|

320MPa |

12Cr2Mo1R-14 |

|

ingredient |

JB 4708 |

|

forms at right side |

|

test of ferrite |

tester calibrated by standard AWS4.2 reads on 6points at least. |

4,4,4,5,5,4 |

12Cr2Mo1R-13 |

|

6,6,7,6,7,7 | <, TD width=136>

12Cr2Mo1R-14

| Te, st&, nbsp; of intergranular corrosion tendency

|

GB4334.5 |

qualified |

12Cr2Mo1R-13 |

| qualified

|

12Cr2Mo1R-14 |

|

bending test | ,

JB4708 |

grade, qualified |

12Cr2Mo1R-13 |

|

grade, qualified |

12Cr2Mo1R-14 |

|

penetration test |

JB/T4730 |

grade, qualified |

12Cr2Mo1R-13 |

|

grade, qualified |

12Cr2Mo1R-14 |

|

ultrasound test |

JB/T4730 |

grade, qualified |

12Cr2Mo1R-13 |

|

grade, qualified |

12Cr2Mo1R-14 |

form14: ingredient of 12Cr2Mo1R-13 (%)

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

Nb |

Cu |

|

0.047 |

0.56 |

0.95 |

0.027 |

0.012 |

19.8 |

0.11 |

9.7 |

0.58 |

0.19 |

form15: ingredient of 12Cr2Mo1R-14 (%)

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

Cu |

|

0.027 |

0.47 |

1.85 |

0.020 |

0.009 |

24.2 |

0.19 |

13.09 |

0.092 |

Test result of 12Cr2Mo1R plate's weld ability:

Welding joints have good performance of tensile, bending, impact and welding.

Other Types of Heavy Plates in Hydrogen Conditions such as Petroleum Chemistry

Composition control:

|

Variety |

Heat No. |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

As |

Sn |

Sb |

J coefficient |

X

coefficient |

|

15CrMoR |

C250030 |

0.13 |

0.15 |

0.41 |

0.007 |

0.001 |

0.92 |

0.48 |

0.0095 |

0.008 |

0 |

84 |

11.15 |

|

SA387Gr11CL2 |

C280000 |

0.14 |

0.47 |

0.38 |

0.007 |

0 |

1.06 |

0.48 |

0.0093 |

0.008 |

0 |

127.5 |

11.13 |

|

C280001 |

0.14 |

0.48 |

0.38 |

0.007 |

0.001 |

1.05 |

0.48 |

0.0081 |

0.007 |

0 |

120.4 |

10.61 |

|

C280002 |

0.14 |

0.46 |

0.4 |

0.007 |

0.001 |

1.04 |

0.48 |

0.0081 |

0.006 |

0 |

111.8 |

10.21 |

|

C280003 |

0.14 |

0.46 |

0.37 |

0.007 |

0.001 |

1.04 |

0.48 |

0.0093 |

0.007 |

0 |

116.2 |

10.73 |

Customer requires that plate model15CrMoR(H) must meet X less than and equel to 15, mole 14Cr1MoR(H)meet J less than and equel to 150. X less than and equel to15, the formula of J&X coefficients is below:

J=(Si%+Mn%)×(P%+Sn%)×104[element content%]

X=(10P+5Sb+4Sn+As)×102[element content%]

Hydrogen Steel Plate 75, 130mm SA387Gr11CL2 (H)

Hydrogen steel plate SA387Gr11CL2 (H) Mechanical Test Properties:

|

Item |

Test Lot |

Sampling Location |

138 |

Heat Treatment |

Rel, MPa |

Rm,MPa |

A, %, |

Impact Power J(-10°C) |

Average Impact Power J |

390°C Tensile |

|

|

SA387Gr11CL2(H) |

S2402L300-1 |

Thickness1/4 |

75 |

920 Normalizing Quick Cool

700 Tempering |

445 |

597 |

25.8 |

228 |

231 |

240 |

233 |

375 |

|

|

R2402L300-1 |

Thickness1/2 |

75 |

430 |

565 |

22.9 |

217 |

209 |

247 |

224 |

358 |

|

|

S2402L300-2 |

Thickness1/4 |

75 |

920 Normalizing Quick Cool,700 tempering+690 simulating treatment after welding(14 hours temperature holding) |

385 |

513 |

31.5 |

205 |

211 |

246 |

221 |

319 |

|

|

R2402L300-2 |

Thickness1/2 |

75 |

370 |

498 |

30.8 |

168 |

159 |

256 |

194 |

317 |

|

|

Item |

Test Lot |

Sampling Location |

138 |

Heat Treatment |

Rel, MPa |

Rm,MPa |

A, % |

Impact Power J(-10°C) |

Average Impact Power J |

390°C Tensile |

|

SA387Gr11CL2(H) |

S2402L271-1 |

Thickness1/4 |

130 |

920 Normalizing Quick Cool

700 Tempering |

425 |

536 |

28 |

207 |

214 |

220 |

214 |

355 |

|

R2402L271-1 |

Thickness1/2 |

130 |

410 |

515 |

26.5 |

138 |

175 |

175 |

163 |

340 |

|

S2402L271-2 |

Thickness1/4 |

130 |

920 Normalizing Quick Cool,700 tempering+690 simulating treatment after welding(14 hours temperature holding) |

366 |

518 |

30 |

230 |

241 |

219 |

230 |

315 |

|

R2402L271-2 |

Thickness1/2 |

130 |

348 |

509 |

28.5 |

205 |

211 |

217 |

211 |

298 |

|