|

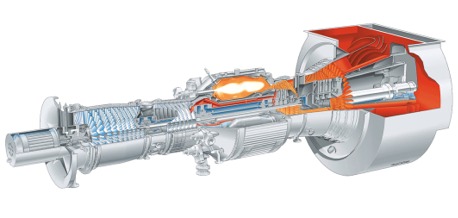

Gas Turbine SGT-500

Power Generation: ISO 19.10 MW(e) / Mechanical Drive: 19.52 MW

The three shaft industrial gas turbine SGT-500 is a light weight, high efficiency, heavy duty machine. It operates reliably in the 15-20 MW power range and can handle a variety of fuels. For both, industrial power generation and mechanical drive, the SGT-500 is a proven unit. The SGT-500 is available as a factory assembled package and provides an excellent power-to-weight ratio. Moreover, the SGT-500 has successfully undergone a comprehensive test program on heavy fuel oil for marine applications.

Fields of Application

• Drive solution for marine applications with heavy fuel oil (HFO) IF180

• Drive solution for centrifugal compressors used in the oil and gas industry

• Simple cycle power generation

• Combined cycle power generation

• Combined heat and power (CHP)

• Power generation for the oil and gas industry

- Onshore power generator for oil field service, refinery application etc.

- Offshore platforms and FPSO vessels

• Reliable, compact, lightweight solution for power generation applications

• High availability, low environmental impact

• Burns heavy fuel oils (HFO), crude oils, residual oils from refining processes, Medium Heavy Crude Oils and Extra Heavy Crude Oils with API gravities as low as 12° or 13° API

Specifications

|

|

|

Power output |

19.10 MW(e) |

|

Fuel |

Natural gas / liquid fuel / dual fuel and other fuels capability on request |

|

Frequency |

50/60 Hz |

|

Electrical efficiency |

33.8% |

|

Heat rate |

10,664 kJ/kWh (10,107 Btu/kWh) |

|

Turbine speed |

3,600 rpm |

|

Compressor pressure ratio |

13:1 |

|

Exhaust gas flow / Temperature |

97.9 kg/s, 369°C (215.9 lb/s, 697°F) |

|

NOx Emissions (with DLE, corrected to 15% O2 dry) |

‘≤ 42 ppmV |

|

|

|

Shaft output |

19.52 MW (26,177bhp) |

|

Fuel |

Natural gas / liquid fuel / dual fuel and other fuels capability on request |

|

Efficiency |

34.5% |

|

Heat rate |

10,432 kJ/kWh (7,373 Btu/bhph) |

|

Turbine speed |

3,450 rpm |

|

Compressor pressure ratio |

13:1 |

|

Exhaust gas flow / Temperature |

97.9 kg/s, 369°C (215.9 lb/s, 697°F) |

|

NOx Emissions (with DLE, corrected to 15% O2 dry) |

‘≤ 42 ppmV |

Maintainability and Availability of the SGT-500

· 55,000 hours between overhauls

· 10,000 hours between inspections

· less than 50 days scheduled downtime in 18 years

· availability in excess of 97%

Crude Oil Capability

· Accepts liquid fuels with viscosities up to 20cSt

· Fuels pre-heated to as high as 150°C

· Possible usage of fuels with viscosities of 750cSt at 50° or higher due to pressurized fuel system

Benefits

· SGT-500 can operate on heavy fuel oil (ideal for Oil & Gas applications)

· Proven outstanding reliability and availability, onshore, offshore and FPSO

· Cyclic, peaking or continuous service

· Outstanding fuel flexibility, fuel changeover on load

· High efficiency, low degradation

· DLE systems for gas and liquid fuel

· State-of-the-art automation and control system

· Casings with blade containment capability and thermal insulation without requirement for forced ventilation

· Complete delivery from OEM - core engine and auxiliary equipment tested in workshop before delivery

· Long intervals between overhauls, low maintenance cost

· Site maintenance or gas generator replacement

· Combustor and hot section accessibility

· E-Service Applications (e.g. Operating Statistics, Upgrades & Enhancements)

· Increases energy efficiency of oilfield operations

· Reduces global CO2 footprint of Heavy Oil production

· Bi-Fueling (Mixed Fuel Operation) reduces the need to flare associated gas

· Core engine exchange concept (in less than 48 hours)

· Longer component life due to lower firing temperatures

Design Concept

The modular, compact design of the SGT-500 facilitates easy on-site service - complete modules can be swiftly exchanged. The SGT-500 contains a twin-shaft gas generator: The low pressure axis contains a 10 stage low pressure compressor and a 2 stage low pressure turbine. The high pressure axis contains an 8 stage high pressure compressor and a 1 stage high pressure turbine. The three-stage power turbine speed is 3,600 rpm for power generation and 3,450 rpm for mechanical drive. In order to increase efficiency, a blade tip clearance adjuster is connected between the power turbine stator and rotor. The gas turbine is available with a conventional or Dry Low Emissions (DLE) combustion system. Both systems provide dual fuel capability, the DLE system also providing extremely low NOX levels.

|