|

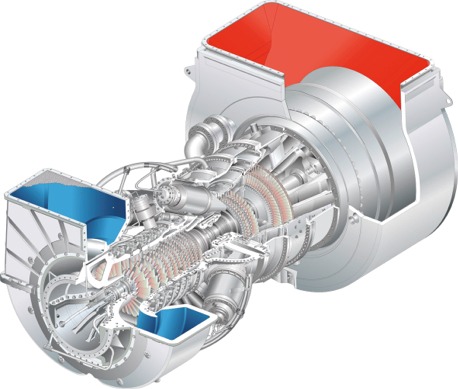

Gas Turbine SGT-400

Power Generation: ISO 12.90 MW(e) / 14.40 MW(e); Mechanical Drive: 13.40 MW / 15.00 MW

Description:

The SGT-400 industrial gas turbine is a blend of 25 years experience and the latest combustion technologies. It offers a power output of 12.90 MW(e) / 14.40 MW(e) for Power Generation and 13.40 MW / 15.00 MW(e) for mechanical drive configuration. The gas turbine is equipped with a Dry Low Emissions (DLE) combustion system, achieving low NOX levels with gas and liquid fuels and a full dual-fuel capability.

In power generation the SGT-400 gas turbine benefits from the turbine’s high simple cycle efficiency (nominal: 34.8 %). In cogeneration applications the unit’s consistent, cost-effective power and steam-raising capability contribute to outstandingly high plant efficiencies. As a highly efficient unit the SGT-400 used in the following fields of application:

· Simple cycle applications

· Combined cycle applications

· Combined heat and power (CHP)

· Power generation for the oil and gas industry

· Onshore power generator for oil field service, refineries etc.

· Offshore platforms and FPSO vessels

For mechanical drive applications the SGT-400 gas turbine is a proven unit for driving compressors and pumps, primarily for the oil and gas industry. It offers outstanding reliability, efficiency and maintainability and is designed to operate on a wide range of gaseous and liquid fuels. Designed for applications where speeds and loads vary, the SGT-400 can operate over a range of different demands:

· Drive solution for pumping applications including crude oil, other refinery product transmission and water injection

· Drive solution for centrifugal compressors used in gas injection, pipeline transmission and boosting, gas processing and similar applications

· Mixed duty applications

|

|

|

Power output |

12.90 MW(e) |

|

14.40 MW(e) |

|

Fuel |

Natural gas / liquid fuel / dual fuel and other fuels capability on request |

|

Frequency |

50/60 Hz |

|

Electrical efficiency |

34.8% |

|

35.2% |

|

Heat rate |

10,355 kJ/kWh (9,815 Btu/kWh) |

|

10,084 kJ/kWh (9,700 Btu/kWh) |

|

Turbine speed |

9,500 rpm |

|

Compressor pressure ratio |

16.8:1 |

|

18.9:1 |

|

Exhaust gas flow / Temperature |

39.4 kg/s, 555°C (86.8 lb/s, 1,031°F) |

|

44.3 kg/s, 546°C (97.7 lb/s, 1,009°F) |

|

NOx Emissions (with DLE, corrected to 15% O2 dry) |

‘≤ 15 ppmV |

|

|

|

Shaft output |

13.40 MW (18,000bhp) |

|

15.00 MW (20,100bhp) |

|

Fuel |

Natural gas / liquid fuel / dual fuel and other fuels capability on request |

|

Efficiency |

36.2% |

|

36.6% |

|

Heat rate |

9,943 kJ/kWh (7,028 Btu/bhph) |

|

9,684 kJ/kWh (6,845 Btu/bhph) |

|

Turbine speed |

9,500 rpm |

|

Compressor pressure ratio |

16.8:1 |

|

18.9:1 |

|

Exhaust gas flow / Temperature |

39.4 kg/s, 555°C (86.8 lb/s, 1,031°F) |

|

44.3 kg/s, 546°C (97.7 lb/s, 1,009°F) |

|

NOx Emissions (with DLE, corrected to 15% O2 dry) |

‘≤ 15 ppmV |

Benefits

· Proven design resulting in high availability and security of supply

· Dual-fuel Dry Low Emissions (DLE) combustion system, meeting the most stringent legislation

· Twin-shaft arrangement for both power generation and mechanical drive, allowing commonality of parts in mixed duty installations

· Competitive cost-to-power ratio

· Compact size

· Site maintainability

· Alternate rapid core engine exchange option, minimizes downtime

The twin-shaft configuration of the SGT-400 provides excellent speed and load turndown flexibility. The design is uniquely simple, employing a single gas generator rotor with twin bearings and a single-stage overhung turbine. The free power turbine is a two-stage overhung design. Rotors are contained in heavy duty casings which are horizontally and vertically split, allowing full site maintenance. The gas turbine is equipped with a Dry Low Emissions (DLE) combustion system, achieving low NOX levels with gas and liquid fuels and a full dual-fuel capability.

With a power turbine speed of 4,800 to 10,000 rpm, generator or pump drive from the power turbine is usually via a speed-reducing gearbox. Most compressor drive applications can be met without the need for a speed-changing gear.

|