|

Siemens Gas Turbine SGT-200

Gas Turbine SGT-200

Power Generation: (ISO) 6.75 MW(e) / Mechanical Drive: 7.68 MW

The robust and compact industrial gas turbine SGT-200 offers an outstanding reliability, efficiency and maintainability. It is designed to operate on a wide range of gaseous and liquid fuels. The turbine is available as a factory assembled package and provides an excellent power-to-weight ratio.

For all electrical power generation and cogeneration applications requiring proven reliability from over 25 years of experience, a single-shaft version of the SGT-200 is used. The on-site maintainability and inherent reliability of the SGT-200 have made it the gas turbine of choice for the oil and gas industry. It is employed on offshore platforms and Floating Production Storage and Off-loading (FPSO) vessels worldwide. Onshore, the SGT-200 is the ideal power generator for oil field service, refinery applications, emergency and standby power generation. The turbine is an efficient and reliable solution for industrial and municipal power generation, i.e. for:

┬Ę Simple cycle applications

┬Ę Combined cycle applications

┬Ę Combined heat and power (CHP)

For mechanical drive applications, i.e. for compressors and pumps in the oil and gas industry, a twin-shaft version of the SGT-200 is used. For the drive of pumps, usually a speed reducing gearbox is used, while most compressor drive applications can be met without the need for a speed-changing gear between the power turbine and gas compressor. The twin-shaft SGT-200 gas turbine is designed for applications where speeds and loads vary. It is used in the following applications:

┬Ę Drive solution for pumping applications including crude oil, other refinery product transmission and water injection

┬Ę Drive solution for centrifugal compressors used in gas injection, pipeline transmission and boosting, gas processing and similar applications

|

|

|

Power output |

6.75 MW(e) |

|

Fuel |

Natural gas / liquid fuel / dual fuel and other fuels capability on request |

|

Frequency |

50/60 Hz |

|

Electrical efficiency |

31.5% |

|

Heat rate |

11,418 kJ/kWh (10,823 Btu/kWh) |

|

Turbine speed |

11,053 rpm |

|

Compressor pressure ratio |

12.2:1 |

|

Exhaust gas flow / Temperature |

29.3 kg/s, 466┬░C (64.5 lb/s, 871┬░F) |

|

NOx Emissions (with DLE, corrected to 15% O2 dry)

|

ŌĆśŌēż 25 ppmV |

|

|

|

Shaft output |

7.68 MW (10,300bhp) |

|

Fuel |

Natural gas / liquid fuel / dual fuel and other fuels capability on request |

|

Efficiency |

33% |

|

Heat rate |

10,906 kJ/kWh (7,708 Btu/bhph) |

|

Turbine speed |

10,950 rpm |

|

Compressor pressure ratio |

12.3:1 |

|

Exhaust gas flow / Temperature |

29.5 kg/s, 489┬░C (65.0 lb/s, 912┬░F) |

|

NOx Emissions (with DLE, corrected to 15% O2 dry)

|

ŌĆśŌēż 15 ppmV |

Benefits

┬Ę Proven design resulting in high availability and security of supply

┬Ę Dual-fuel Dry Low Emissions (DLE) combustion system, meeting the most stringent legislation

┬Ę Compact size

┬Ę Competitive cost-to-power ratio

┬Ę Site maintainability

┬Ę Alternate rapid core engine exchange option, minimizes downtime

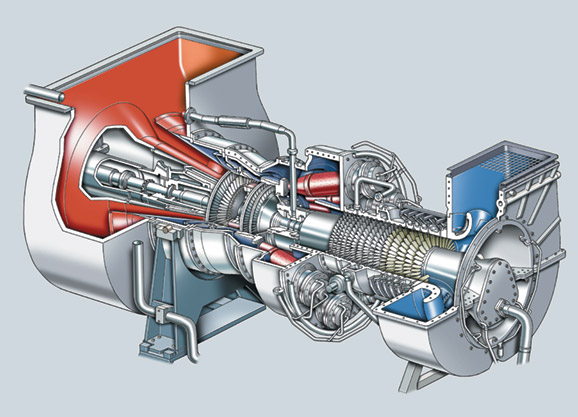

For power generation, a single-shaft configuration of the SGT-200 with a twin bearing gas generator, twin bearing power turbine and heavy duty casings is used. The single shaft configuration provides excellent load acceptance and rejection characteristics, allowing robust and reliable operation in all applications.

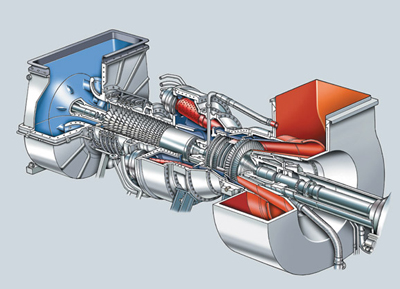

For all mechanical drive applications, a twin-shaft configuration of the SGT-200 provides excellent speed and load turndown flexibility. The design is uniquely simple, employing a single gas generator rotor with twin bearings and a two-stage overhung turbine. Rotors are contained in heavy duty casings which are horizontally and vertically split. For all mechanical drive applications, a twin-shaft configuration of the SGT-200 provides excellent speed and load turndown flexibility. The design is uniquely simple, employing a single gas generator rotor with twin bearings and a two-stage overhung turbine. Rotors are contained in heavy duty casings which are horizontally and vertically split.

|