|

1. Basic performance parameters

1.1 The Performance of QD128 Gas Turbine

|

Main performance

of basic load

(ISO atmospheric condition) |

Parameter |

Value |

Unit |

|

Rated power |

11500 |

kW |

|

Heat efficiency |

27 |

% |

|

Heat consumption |

13333 |

kJ/kWh |

|

Main performance

of peaking load

(ISO atmospheric condition) |

Parameter |

Value |

Unit |

|

Rated power |

12800 |

kW |

|

Heat efficiency |

27.6 |

% |

|

Heat consumption |

13043 |

kJ/kWh |

1.2 Other Parameters

|

S/N |

Name |

Unit |

Basic load |

Peaking load |

|

1 |

Air flow |

kg/s |

60.07 |

62.45 |

|

2 |

Total pressure of pressure outlet |

10 5Pa |

11.92 |

12.63 |

|

3 |

Temp. of combustion chamber outlet |

K |

1301 |

1350 |

|

4 |

Low pressure speed |

r/min |

10174 |

10431 |

|

5 |

High pressure speed |

r/min |

11791 |

12008 |

|

6 |

Air flow of power turbine inlet |

kg/s |

60.47 |

62.94 |

|

7 |

Total pressure of power turbine inlet |

10 5Pa |

2.57 |

2.732 |

|

8 |

Total temp. of power turbine inlet |

K |

943 |

981 |

|

9 |

Power turbine speed |

r/min |

4700 |

4700 |

|

10 |

Total temp. of exhaust volute inlet |

K |

767 |

787 |

|

11 |

Total pressure of exhaust volute outlet |

10 5Pa |

1.013 |

1.013 |

1.3 First overhaul period of gas turbine

Gas generator not less than 8000h

Power turbine not less than 40000h

1.4 Enclosure Size

Size of gas turbine enclosure 8400(L)Ă—3300(W)Ă—4280(H)mm

Size of generator enclosure 8400(L)Ă—3300(W)Ă—4280(H)mm

1.5 Enclosure weight

Weight of gas turbine enclosure 36.3T

Weight of generator enclosure 70.073T

1.6 The condition needed

Cycle cooling water

Feedwater pressure:0.4Mpa;

Feedwater temperature: Power supply: 380/220V;

Nature gas inlet pressure: 2.3Mpa;

Nature gas inlet temperature: 15Nature gas inlet flow:4500-4800 Nm3/h

2. Performance characteristic

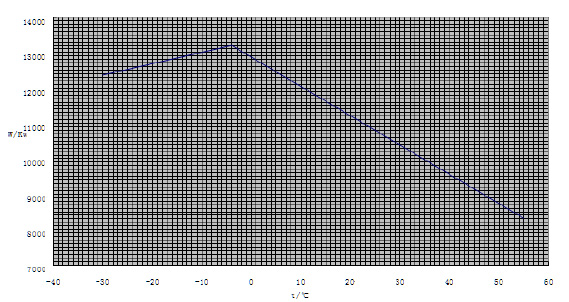

4.1 Power of gas turbine versus atmospheric temperature characteristic (Fig.1)

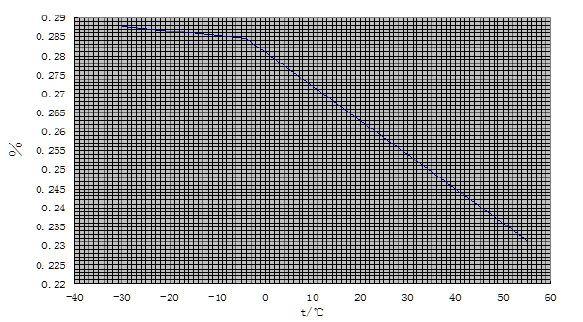

4.2 Heat efficiency of gas turbine versus atmospheric temperature characteristic (Fig.2)

Power of gas commercial turbine versus atmospheric temperature characteristic (Fig.1)

Heat efficiency of gas turbine versus atmospheric temperature characteristic (Fig.2)

3. Supply scope and Supply cycle

3.1 Name of equipment

QD128 gas turbine generating set, which is designed, manufactured and supplied by Liming Aero-engine Group Corporation, Ltd.

3.2 Supply Scope

QD128 industrial gas turbine set

One complete QD128 gas turbine generating set is composed of gas turbine module (which is composed of gas turbine generating set and gas turbine auxiliary equipments), generator module (which is composed of 15MW generator and generator auxiliary equipments), other auxiliary equipments, electric system and so on.

3.2.1 Gas turbine generating set including:

Gas generator;

Inlet section

Power turbine

Start-up system& accessory gearing

Hydraulic pressure set & connected pipelines and cables

Fuel modulation system

Lubricant system

Control system (including control, measurement, and protection for assistant system)

Independent installment & fix installment

Pipeline system

The meters, sensors, transducer and cables and any necessary equipment

3.2.2 Auxiliary equipment including:

Enclosure

The foundation of gas turbine generating set and bound equipment

Gas turbine examining and repair platform

Electric heater inside Gas turbine enclosure

Speed- reducer gearbox (with main lubricant pump)

High-speed coupling and protector

Illumination inside enclosure (including emergency illumination) and electric element for repair

Supervising system (with video cam, far-distance display system, not provided with the set)

3.2.3 Generator set including

15MW generator

2 sets sliding bearing and bearing components

CO2 fire extinguishing sensor of generator

Foundation of bearing generator and axletree

Generator excitation system

Generator leaking examination and pipeline

3.2.4 Auxiliary equipment of generator including

Generator enclosure

Foundation of generator and assistant equipment and lubricant system

Instrument panel

Generator coil out protecting shield

Low speed coupling and protecting shield

Generator examination and repair platform

3.2.5 Auxiliary equipment of system including

Quadratic ground plate, earth bolts unit and adjustor for stabilization

Inlet system

Back flushing control and pipeline control system of gas turbine

Lubricant system ( one AC machine drive gasoline pump, one DC machine drive gasoline pump, lubricant two-way switchable filter, lubricant unilateralism filter, temperature control components, stainless steel gasoline entrance and return pipeline, valve, measurement sensor, and etc)

CO2 fire extinguishing system

Enclosure ventilation

Cooling system

Fuel gas inlet fine filter

Fuel gas voltage stabilizing measuring set (not provided with the set)

Oil & water cooler

Lubricant- gas separator

Gas turbine compressor cleaning system

Effluent system

Connection and adjust components of each equipments

Flanges of pipeline interface.

3.2.6 Electric system including:

DC system (two 220V charge cabinet, one 220V charge cabinet, 2 accumulator cabinets)

Low voltage system (one low voltage coil in cabinet, 3 motor control cabinet, 2 gas turbine control cabinet, 1 power electric power distribution cabinet, 1 fire extinguishing control cabinet)

High voltage system (1 generator control cabinet, 1 generator excitation cabinet, 1 high voltage coil in cabinet, 1 high voltage coil out cabinet)

Heat engineering instrument system

, Auxiliary test and control system

Earthing system (underground system is not included)

Primary connection cable from generating set to high-pressure & low-pressure in control room.

3.3 Supply cycle:12 months

4. Main equipment list for QD128 Combined Cycle Gas Turbine Generator Plant

|

Item |

Main Area |

|

Main Equipment |

Specification |

|

1 |

Gas Turbine Genset Island |

A |

Gas Turbine set |

Dimension:

8330mmX3200mmX3800mm

Rated capacity: 11500kW

Heat Efficiency: 27% |

|

B |

Alternator |

Dimension:

8225mmx3200mmx3400mm

Rated power: 15000kW

Rated Voltage: 10.5kV

Frequency: 50Hz

Efficiency: 97.2% |

|

C |

Air Inlet system |

Inlet Air Flow: 68kg/s

Outer dimension

10003mmĂ—5636 mmx12102 mm |

|

D |

Exhaust System |

Exhaust temperature:488 C Degree

Exhaust Pressure: 0.1Mpa

Flow: 210t/h |

|

2 |

Heat Recovery System |

A |

Boiler |

Rated steam flow: 28 t/h

Steam pressure: 2.45 Mpa

Steam temperature: 400C Degree (overheat)

Exhaust temperature: 150C Degree

Water temperature: 150C degree |

|

B |

Chimney |

20m |

|

3 |

Steam Turbine system |

(1) |

Steam Turbine |

Inlet Pressure: 2.35Mpa

Inlet Temperature: 390C

Steam consumption: 5.6t/MW |

|

(2) |

Alternator |

Rated power: 6000/3000kW

Voltage: 10.5kV

Frequency: 50Hz |

|

(3) |

HV, LV distribution system |

|

|

(4) |

Steam distribution cylinder |

|

5. Main equipment list for QD128 Co Generation Gas Turbine Generator Plant

|

Item |

Main Area |

|

Main Equipment |

Specification |

|

1 |

Gas Turbine Genset Island |

A |

Gas Turbine set |

Dimension:

8330mmX3200mmX3800mm

Rated capacity: 11500kW

Heat Efficiency: 27% |

|

B |

Alternator |

Dimension:

8225mmx3200mmx3400mm

Rated power: 15000kW

Rated Voltage: 10.5kV

Frequency: 50Hz

Efficiency: 97.2% |

|

C |

Air Inlet system |

Inlet Air Flow: 68kg/s

Outer dimension

10003mmĂ—5636 mmx12102 mm |

|

D |

Exhaust System |

Exhaust temperature:488 C Degree

Exhaust Pressure: 0.1Mpa

Flow: 210t/h |

|

2 |

Heat Recovery System |

A |

Boiler |

Rated steam flow: 29 t/h

Steam pressure: 1.25 Mpa

Steam temperature: 194C Degree (saturated)

Exhaust temperature: 150C Degree

Water temperature: 20C degree |

|

B |

Chimney |

20m |

6. Quotation of the one set of combined cycle QD128:

The efficiency of QD128 combined cycle power plant as I have sent you the proposal and specficication is about 42% (27% for singel cycle, 15% for heat recovery system) and the parasisitic power consumption is 450kw. the heat recovery power capacity is around 4.5mw under ISO condition, and natural gas consumption is 4800-5300 Cubic meter per hour.

The quotation of the combined cycle power is about 10 million USD per unit, FOB China port, and of course it will change to technical and financing conditions.

You are welcome to inspect our power plant projects in China by using our QD128 gas turbine generator which can use both gas and diesel oil as fuel.

7. Performance credit

2 QD128 gas turbine projects have been build including Henan Wenliu Power Plant (cogeneration of heat and power), Helongjiang Daqing Weiya Power Plant (cogeneration of heat and power). After 10,000 hours continuous test run, the reliability and each technical targets have reached the standard of internationally mature units. In 2008, one unit was sold to Ganshu Akeshai and right now it is under construction (cogeneration of heat and power). In 2009, one unit was sold to Shanxi Luan Group,will generate in 2011.

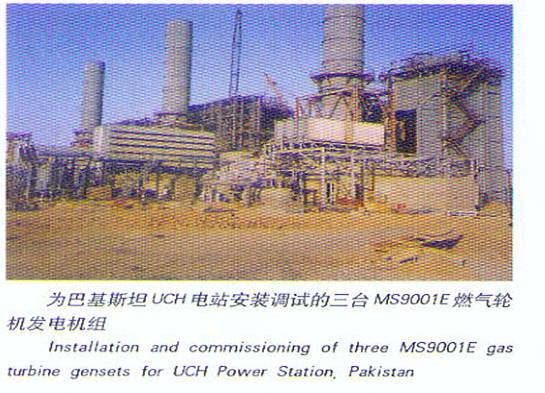

3 sets of FR9E gas turbine simple cycle power generators were installed and commissioned in Pakistan Uqi(UCH) in March 1997. In 2010, 3 sets of PG9171E gas turbine combined cycle power generators were installed and commissioned in Pakistan.

Power plant in Heilongjiang Daqing Beiya, 2005

Power plant in Henan Liuwen, 2003

Picture of Gas Turbine Power Plant in Ganshu Akeshai, 2009

|