|

Water Treatment Equipment

|

|

|

Jianghan Petroleum Machinery Plant (JPMP) of Jianghan Petroleum Administration Bureau is one of manufacturers for oil engineering and water treatment equipment. JPMP has been ISO 9001 certified, and was granted to use API Monogram of 4F, 8C and 11E. JPMP has ASME certificate with U stamp for fabrication of pressure vessels.

For over 20 years, JPMP has developed complete series sewage treatment equipment for oily water in oil production, refinery in onshore and offshore oilfields at extreme temperature, industrial sewage and domestic sewage to meet requirements of production and environment. The water treatment equipment fabricated by JPMP were exported to the south America.

Main products:

|

JHX5230TJC Well-Flushing Truck |

JHX5240TJC Well-Flushing Truck |

|

JHX5250TJC Well-Flushing Truck |

CYG Corrugated Plate Interceptor |

|

Jet floatation units |

Modified fiber ball filter |

|

Fiber ball filter |

Dual medium filter |

|

Walnut shell filter |

SHS Multifunctional biochemical disposal unit |

|

|

JHX5230TJC Well-Flushing Truck

|

|

Truck-mounted units:

1. Cyclone desander 2. Corrugated plate interceptor

3. Walnut shell filter 4. Fiber ball filter

Specifications:

|

Flushing flow rating(m³/h) |

30 |

|

Flushing pressure rating(MPa) |

12.5 |

|

Working pressure for truck-mounted units(MPa) |

Cyclone desander: <=1.0 |

|

Fiber ball filter:<=0.6 |

|

CPI:<=0.6 |

|

Walnut shell filter:<=0.6 |

|

Water temperature(ºC) |

<=60 |

|

Inlet water(mg/L) |

Water from injection well |

|

Outlet water(mg/L) |

Oil content:<=5 |

|

Suspended solid content: <=3 |

Characteristic:

|

Effective triplex pump |

Pressure:12MPa |

|

Flow rating: 30m³/h |

|

Rated speed:300r/mim |

|

Water treatment process |

Applicable treating processes are used for different water to ensure oil content is less than 5mg/L and suspended solids less than 3mg/L in filtered water. |

|

Well-flushing process |

Conventional well-flush flow process: Casing-tubing-drain

JPMP well-flush truck process: Casing-tubing-well-flush truck-casing. |

|

Low temperature resistance |

Electric tracing insulation with constant power is provided to ensure no freezing piping. |

|

|

JHX5240TJC Well-Flushing Truck

|

|

Truck-mounted units:

1. Walnut shell filter 2. Dual medium filter

3. Separator 4. Basket fiber

Specifications:

|

Flushing flow rating(m³/h) |

25.3 |

|

Flushing pressure rating(MPa) |

12.5 |

|

Working pressure for truck-mounted units(MPa) |

Basket filter <=1.0 |

|

Separator <=0.6 |

|

Dual medium filter <=0.6 |

|

Walnut shell filter <=0.6 |

|

Water temperature(ºC) |

<=60 |

|

Inlet water(mg/L) |

Oil content <=300 |

|

Suspended solid content <=2000 |

|

Outlet water(mg/L) |

Oil content <=5 |

|

Suspended solid content <=3 |

Characteristic:

|

Effective triplex pump |

Pressure 12.5MPa |

|

Flow rating 25.3m³/h |

|

Rated speed 293r/mim |

|

Water treatment process |

Applicable treating processes are used for different water to ensure oil content is less than 5mg/L and suspended solids less than 3mg/L in filtered water. |

|

Well-flushing process |

Conventional well-flush flow process: Casing-tubing-drain

JPMP well-flush truck process: Casing-tubing-well-flush truck-casing. |

|

Low temperature resistance |

Electric tracing insulation with constant power is provided to ensure no freezing piping. |

|

|

JHX5250TJC Well-Flushing Truck

|

|

Truck-mounted units:

1. Cyclone desander 2. Coalescer

3. Corrugated plate interceptor 4. Walnut shell filter

Specifications:

|

Flushing flow rating(m³/h) |

30 |

|

Flushing pressure rating(MPa) |

12.5 |

|

Working pressure for truck-mounted units(MPa) |

Cyclone desander <=1.0 |

|

Coalescer:0.6 |

|

CPI: <=0.6 |

|

Walnut shell filter: <=0.6 |

|

Water temperature(ºC) |

<=60 |

|

Inlet water(mg/L) |

Oil content <=300 |

|

Suspended solid content <=2000 |

|

Outlet water(mg/L) |

Oil content <=5 |

|

Suspended solid content <=3 |

Characteristic:

|

Effective triplex pump |

Pressure 12.5MPa |

|

Flow rating 25.3m³/h |

|

Rated speed 293r/min |

|

Water treatment process |

Applicable treating processes are used for different water to ensure oil content is less than 5mg/L and suspended solids less than 3mg/L in filtered water. |

|

Well-flushing process |

Conventional well-flush flow process: Casing-tubing-drain.

JPMP well-flush truck process: Casing-tubing-well-flush truck-casing. |

|

Low temperature resistance |

Electric tracing insulation with constant power is provided to ensure no freezing piping. |

|

|

CYG Corrugated Plate Interceptor

|

|

Corrugated plate interceptor (CPI) is developed on the basis of "shallow pool" and gravity separation. When entering into the stainless steel corrugated plate with tear holes as in a labyrinth, oily water will change flow direction and intersection. Small oil droplets collide and coalesce during floatation, dispersed droplets merge big ones to increase floating speed of oil droplets and falling speed of water. The floated oil is collected in the sump cell to drain out at regular intervals. The separated water will enter into water cell through the collector, and drain into the next stage for treatment automatically through the regulating valve.

CPI made by JPMP has been widely used for disposal of oily water in oilfield, service water and desalted water.

Specifications:

|

Description |

Index |

Description |

Index |

|

Design pressure(MPa) |

0.6 |

Resistance loss(MPa) |

<=0.05 |

|

Design temperature(ºC) |

80 |

Retention time(min) |

20 |

|

Inlet oil content(mg/l) |

2500~5000 |

Oil removal efficiency(%) |

=>85 |

Parameters:

|

Model |

Vessel diameter(mm) |

Capacity(m3/h) |

Weight(kg) |

Flange connection(PN1.0 GB9119.7-88) |

|

Net |

Operation |

Inlet |

Flush |

Drain |

Vent |

|

CYG30/0.6 |

1400 |

30 |

3280 |

13280 |

DN80 |

DN50 |

DN25 |

DN80 |

|

CYG60/0.6 |

1600 |

60 |

5400 |

25400 |

DN100 |

DN50 |

DN50 |

DN100 |

|

CYG100/0.6 |

2000 |

100 |

9800 |

43000 |

DN150 |

DN80 |

DN50 |

DN100 |

|

CYG160/0.6 |

2200 |

160 |

12500 |

62500 |

DN200 |

DN80 |

DN50 |

DN150 |

|

CYG200/0.6 |

2400 |

200 |

15300 |

81300 |

DN250 |

DN100 |

DN50 |

DN150 |

|

CYG250/0.6 |

2800 |

250 |

19800 |

110000 |

DN250 |

DN100 |

DN50 |

DN200 |

|

CYG320/0.6 |

3000 |

320 |

27600 |

127600 |

DN250 |

DN100 |

DN50 |

DN200 |

|

CYG400/0.6 |

3400 |

400 |

31640 |

164640 |

DN300 |

DN150 |

DN80 |

DN250 |

|

CYG500/0.6 |

3600 |

500 |

34000 |

200000 |

DN300 |

DN150 |

DN80 |

DN250 |

|

CYG640/0.6 |

3800 |

640 |

40000 |

255000 |

DN350 |

DN150 |

DN100 |

DN250 |

|

|

Jet Floatation Units

|

|

Disposal of sewage by jet floatation is a new technology in recent years. The jetting fluid that may be sewage or purified water forms negative pressure in the suction cell of ejector to draw in air. When the air passes through mixing cell, it is cut to tiny bubbles that will adheres oil droplets and solid particles in the air floatation cell and rise upward for removal by skimmer.

Compared with other sewage treatment equipment, jet floatation unit is applicable for disposal of industrial sewage in oilfield, refinery, petrochemical and other industries with its short retention time, low power consumption (only 50~60% of impeller floatation unit), high removal efficiency, easy operation, safety and reliability. FXP floatation unit can operate under fully closed conditions without pollution to the environment. The unit is taken as post treatment behind the primary gravity separator. It is also used for sewage treatment in the refinery and petrochemical industry.

Specifications:

|

Description |

Parameter |

Description |

Parameter |

|

Capacity (each)(m3/h ) |

30-640 |

Vessel diameter(mm) |

Ø 1200-Ø 3800 |

|

Design pressure(Mpa) |

0.6 |

Operating pressure(Mpa) |

<=0.1 |

|

Design temperature(ºC) |

80 |

Operating temperature(ºC) |

<=60 |

|

Inlet oil content(mg/L) |

<=200 |

Outlet oil content(mg/L) |

<=20(Adding chemical) |

|

|

Modified Fiber Ball Filter

|

|

Modified fiber filers developed by JPMP improve water quality and filter velocity of oily water in oilfield.

The modified fiber balls, made of oil resistant fiber, feature stable chemical property, high temperature resistance, long service life, wide applications, large specific surface area, high void fraction, strong intercepting ability, low backwash strength, effective regeneration and short generation time of filter medium. As different resistance on the filter bed during filtering, an ideal status of loose upper filter layer and close lower layer will improve equipment accuracy and filtering velocity. The filter may operate under remote control.

Specifications:

|

Description |

Parameter |

|

, Capacity (each)(m3/h) |

15~300 |

|

Design pressure(MPa) |

0.6 |

|

Filtering velocity(m3/h ) |

30 |

|

Filter resistance (Single stage, in parallel)(MPa ) |

<=0.15 |

|

Backwash strength(L/m2s ) |

5.0 |

|

Design , , temperature(ºC),

|

80 |

|

Operating cycle(h) |

8~72 |

|

Filter resistance (2 stages, in series)(MPa) |

<=0.3 |

|

Inlet water |

SS(mg/L) |

<=20 |

Oil(mg/L) |

<=20 |

|

Outlet water |

SS(mg/L) |

<=3 |

Oil(mg/L) |

<=2 |

SSsize |

<=2um(>85%) |

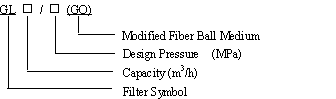

Model:15m3/h~300m3/hcapacity is available upon request.

Model explanation:

|

|

Fiber Ball Filter

|

|

The fiber balls, made of fiber wires, feature stable chemical property, high temperature resistance, long service life, wide applications, large specific surface area, high void fraction, strong intercepting ability, low backwash strength, effective regeneration and short generation time of filter medium. As different resistance on the filter bed during filtering, an ideal status of loose upper filter layer and close lower layer will improve equipment accuracy and filtering velocity. The filter may operate under remote control.

Characteristics:

|

Description |

Parameter |

|

Capacity (each)(m3/h) |

10~250 |

|

Operating cycle(h) |

8~48 |

|

Water quality |

Inlet suspended solids |

<=20 |

|

Outlet suspended solids |

<=3 |

Specifications:

|

Model |

Capacity(m3/h) |

Vessel diameter(mm) |

Mixer power(kw) |

Connection |

Overflow |

Weightkg(kg) |

|

Inlet &outlet |

Drain & vent |

|

GL15/0.6 |

15 |

800 |

1.5 |

DN50 |

DN25 |

R3/4 |

825 |

|

GL20/0.6 |

20 |

1000 |

3 |

DN80 |

DN25 |

R3/4 |

875 |

|

GL30/0.6 |

30 |

1200 |

4 |

DN80 |

DN50 |

R3/4 |

1510 |

|

GL40/0.6 |

40 |

1400 |

4 |

DN100 |

DN50 |

R3/4 |

1695 |

|

GL60/0.6 |

60 |

1600 |

7.5 |

DN100 |

DN50 |

R3/4 |

1970 |

|

GL70/0.6 |

70 |

1800 |

7.5 |

DN100 |

DN50 |

R3/4 |

2185 |

|

GL90/0.6 |

90 |

2000 |

7.5 |

DN125 |

DN50 |

R3/4 |

2790 |

|

GL110/0.6 |

110 |

2200 |

11 |

DN150 |

DN50 |

R3/4 |

3285 |

|

GL130/0.6 |

130 |

2400 |

11 |

DN150 |

DN50 |

R3/4 |

3485 |

|

GL150/0.6 |

150 |

2600 |

11 |

DN150 |

DN50 |

R3/4 |

4520 |

|

GL180/0.6 |

180 |

2800 |

18.5 |

DN200 |

DN50 |

R3/4 |

5555 |

|

GL210/0.6 |

210 |

3000 |

18.5 |

DN200 |

DN50 |

R3/4 |

6285 |

|

GL240/0.6 |

240 |

3200 |

18.5 |

DN200 |

DN50 |

R3/4 |

7545 |

|

GL270/0.6 |

270 |

3400 |

22 |

DN200 |

DN50 |

R3/4 |

8495 |

|

GL300/0.6 |

300 |

3600 |

22 |

DN250 |

DN50 |

R3/4 |

9660 |

|

|

Dual Medium Auto Filters

|

|

Dual medium parallel filter is developed by JPMP and Shengli Oilfield Design Institute based on foreign advanced technology for disposal of sewage and clean water in oilfield. The filter characters compact structure, easy operation, automatic control, stable running, high filter velocity, large capacity, high filter accuracy, thorough backwash and simple maintenance.

Anthracite, silica sand or garnet is adopted as filtration medium to form an ideal filter bed for interception. Filtering medium with different gravity will not be mixed. The Dual medium filter is applicable for disposal of oily water in oilfield, as well as well for sewage treatment in metallurgical, chemical, textile industries.

Single pedestal technique index sign:

|

Description |

Parameter |

Description |

Parameter |

|

Capacity (each)(m3/h) |

5~150 |

Filter resistance(MPa) |

<=0.12 |

|

Design pressure(MPa) |

0.6 |

Backwash strength,(l/m2*s) |

14.5 |

|

Design temperature(ºC) |

80 |

Air flush strength(l/m2*s) |

10 |

|

Inlet water |

Oil(mg/l) |

20 |

Outlet water |

Oil(mg/l) |

5 |

|

SS(mg/l) |

30 |

SS(mg/l) |

3 |

Single pedestal technique characteristic parameter:

|

Model |

Normal diameter(DN) |

Capacity(m3/h) |

Volume(m3) |

Connection |

|

Inlet & outlet,Water & backwash |

Drain |

Vent |

|

GL5/0.6(s) |

DN800 |

5 |

1.08 |

DN80 |

DN50 |

DN50 |

|

GL10/0.6(s) |

DN1000 |

10 |

1.74 |

DN80 |

DN50 |

DN50 |

|

GL15/0.6(s) |

DN1200 |

15 |

2.58 |

DN100 |

DN50 |

DN50 |

|

GL20/0.6(s) |

DN1400 |

20 |

3.61 |

DN100 |

DN50 |

DN50 |

|

GL30/0.6(s) |

DN1600 |

30 |

4.89 |

DN125 |

DN50 |

DN50 |

|

GL40/0.6(s) |

DN1800 |

40 |

6.36 |

DN125 |

DN50 |

DN50 |

|

GL50/0.6(s) |

DN2000 |

50 |

7.94 |

DN150 |

DN50 |

DN50 |

|

GL60/0.6(s) |

DN2200 |

60 |

10.1 |

DN150 |

DN50 |

DN50 |

|

GL70/0.6(s) |

DN2400 |

70 |

12.3 |

DN200 |

DN100 |

DN50 |

|

GL90/0.6(s) |

DN2600 |

90 |

14.5 |

DN200 |

DN100 |

DN50 |

|

GL100/0.6(s) |

DN2800 |

100 |

16.9 |

DN200 |

DN100 |

DN50 |

|

GL110/0.6(s) |

DN3000 |

110 |

20.4 |

DN250 |

DN100 |

DN50 |

|

GL120/0.6(s) |

DN3200 |

120 |

25.3 |

DN250 |

DN100 |

DN50 |

|

GL130/0.6(s) |

DN3400 |

130 |

29.4 |

DN250 |

DN100 |

DN50 |

|

GL150/0.6(s) |

DN3600 |

150 |

33.6 |

DN250 |

DN100 |

DN50 |

|

|

Walnut Shell Filter

|

|

JPMP developed and fabricated KWL-1 walnut shell filter in 1987 for treating oily water in Shengli Oilfield to improve water quality, reduce treating cost and enhance recovery ratio. The filter was awarded national prize. Now, series of walnut shell filters with various backwash methods and capacities have been developed for over 10 years. Specially treated walnut shells character large surface area, high adsorbability and removing efficiency. During mixing, walnut shells will rub each other to remove filth on the shells to regenerate as hydrophilic, oleophobic and stable chemical properties. Deep bed principle is used in the filter to enhance intercepting ability. The filters are suitable for disposal of oily water in oilfield and other industries.

Technique characteristic:

|

Description |

Parameter |

|

Capacity (each)(m3/h) |

10~425 |

|

Backwash strength(L/m3s) |

6.3 |

|

Design pressure(MPa) |

0.6~2.0 |

|

Design temperature(ºC) |

80 |

|

Filter velocity(m/h) |

24~34 |

|

Backwash time(min ) |

20~25 |

|

Filter resistance (single stage, in parallel)(MPa) |

<=0.1 |

|

Filter resistance (each unit)(MPa ) |

<=0.12 |

|

Primary filtration(mg/L) |

Inlet |

SS<=100 |

Oil content |

<=100 |

|

Outlet |

SS<=100 |

Oil content |

<=10 |

|

Working cycle(h) |

8~25 |

|

Filter resistance (2 stages, in series)(MPa) |

1~3% |

|

Inlet water(mg/L) |

SS |

<=50 |

Oil |

<=50 |

|

Outlet water(mg/L) |

SS |

<=10 |

Oil |

<=10 |

Model:

|

GLWA10/0.6 |

GLWA15/0.6 |

GLWA30/0.6 |

GLWA40/0.6 |

GLWA50/0.6 |

|

GLWA60/0.6 |

GLWA80/0.6 |

GLWA90/0.6 |

GLWA100/0.6 |

GLWA130/0.6 |

|

GLWA150/0.6 |

GLWA180/0.6 |

GLWA200/0.6 |

GLWA220/0.6 |

GLWA250/0.6 |

|

|

SHS Multifunction biochemical disposal device

|

|

SHS multifunction biochemical disposal system, a new sewage disposal equipment used in oilfield, is developed by cooperation between JPMP and Qinghua University by using the principle of biological reactor which is a new sewage process technology came out in Europe and America in late 1980s. The technology not only resolves the problem of sewage discharge in oilfield but also is suitable to modification for old water treatment engineering.

Application:

Suitable for disposal of sewage to be discharged out in onshore and offshore oilfields.

Suitable for disposal of sewage from petrochemical, paper mill, dye printing industry, textile, pharmaceutical industries and sanitary wastewater as well.

Features:

1. High efficiency of removal COD, high capability of impact resistance, simple structure and easy operation.

2. Low cost of construction and operation as no need for secondary settling basin.

3. As the untreated water is enclosed, there is no offensive odor.

4. Modularization of the unit makes it easy for extension.

5. Blower fan, pump and valves are controlled by PLC, so the unit is run automatically without manual operation. |

|

|

|