|

Compressor Series

|

|

|

No.3 Machinery Plant of Jianghan Petroleum Administration bureau mainly produces RDS series natural gas compressor , CNG compressor for CNG/NGV(Natural Gas Vehicle) refueling station and piston type air compressors such as 2V,2W,WY and 1VF etc. and OGD series single screw air compressors and its parts. It is production base of Sinopec for compressor, is the only producer in oil and petrochemical industry that adopts the imported technology to manufacture large and medium sized natural gas compressor . It has been awarded IS09001 quality certification, gained certificate and marking certificate of adopting International standard, gained material furnishment exporting certificate of China Oil. The RDS and CNG gas compressor have been obtained the state key new product certificate. We have build a production and investigation base in Dongxihu developing section in Wuhan city in 2004 for producing 15 sets RDS serial gas compressors and 35 sets CNG compressors for vehicle gas refueling station and 800 sets OGD single screw air compressors per year.

Main production:

|

CNG compressor for vehicle gas refueling station |

OGD single screw air compressor |

|

RDS series natural gas compressor |

air compressor | |

|

CNG compressor for vehicle gas refueling station

|

|

CNG serial compressor unit is a fully enclosured, air cooled, skid mounted unit developed by the plant itself. It is a opposed counter-balanced reciprocating compressor with the feathers of weather proof and highly reliable operation designed uniquely for CNG (Compressed Natural Gas) refueling station. Through assessment of Sinopec, it has reached advanced level in the country.

Purpose:

CNG serial compressor is mainly used for natural gas refueling station, and can also be used in petroleum, chemical industry, mines and others, compressed natural gas, nitrogen, air, nitrogen and oxygen, carbon dioxide, propane and a large number of gases.

Technical feature:

(1) Integrated installation with prizing£¬convenient for users' installation at the site, with lower installation cost.

(2) Extremely low specific pressure design, lubrication of the bearing face is excellent, lifetime of easily damaged parts is long.

(3) Cylinder and process between levels are entirely wind cooled, without need of water source, saving cost for setting up the station, specially adaptable to be used in very cold areas.

(4) The motion mechanism adopts reversed lubrication mode, ensuring the lubrication for parts difficult to be lubricated, at the same time, there is no oil hole on the crankshaft, thus raised fatigue lifetime of crankshaft.

(5) Adopt intelligence PLC control system, realize automatic start and shut down, fault alarm indication and other controls for the unit. At the same time, it has reserved control points, and realizes automatic control over the gas station and other facilities.

(6) Equipped with integrated sound insulation housing and inlet and outlet air muffler, reduced noise of the unit and curbed the long distance spreading of the noise.

Parameter table:

|

Model |

Discharge capacity(m3/h) |

Suction pressure(MPa) |

Discharge pressure(MPa) |

Compres-sion series |

Compressor speed of running(r/min) |

Motor power(kw) |

|

2D4-3/3-250 |

420~740 |

0.15~0.35 |

25.0 |

4 |

980 |

110~160 |

|

2D4-0.5/14-250 |

430~800 |

1.4~3.0 |

25.0 |

3 |

740 |

55~90 |

|

2D4-1.45/8-250 |

700~1350 |

0.8~1.6 |

25.0 |

3 |

980 |

132~185 |

|

2D8-4.7/3-250 |

750~1480 |

0.2~0.5 |

25.0 |

4 |

980 |

160~300 |

|

4D8-2.9/8-250 |

1400~2680 |

0.8~1.6 |

25.0 |

3 |

980 |

230~350 |

|

4D8-1.1/6-250 |

1462~2735 |

0.6~1.2 |

25.0 |

4 |

980 |

251~400 |

Note:we can provide standard station and main station CNG compressors to users with special operating conditions, the max. suction pressure can reach 3.0Mpa. |

|

OGD single screw air compressor

|

|

The latest OGD single screw air compressor is the forth generation product, screw of duo-tread contact trace and start joggle are used for mainframe, which has unexampled and advanced quality of the piston air compressor and dual screw air compressor. OGD single screw air compressor is one of the latest technologies of electro-mechanic integrative all-purpose devices in the world, which is the ideal product as a substitute of imported compressor for the domestic users.

Purpose:

OGD single screw air compressor is widely used for high-speed train of railway, ship, architecture, irrigation works, factory, mine, medicine, mining, instrument and meter, petroleum, chemical industry etc. and other industries, such as: the field which uses compressed air as power, including pneumatic tool, pneumatic clamp, automatic control, sand blast, spray-painted, blowing and cleaning, air inflation and gas convey and so on.

Technical feature:

(1)The structure is reasonable, and perfect balance;

(2)The noise and vibration are low, and meeting the requirements of environment protection;

(3)Highly precise rotor;

(4)Save energy and high efficiency;

(5)Advanced PC control panel;

(6)Perfect airflow adjustment;

(7)Complete safety protective device;

(8)Expenses of installation and maintenance are low;

(9)Competence of individual set is large, without clearance;

Model:OGD22, OGD30, OGD37, OGD45, OGD55, OGD75, OGD90, OGD110, OGD132, OGD160, OGD200, OGD250,Etc.

OGD22, OGD55, OGD110, OGD250 Technical parameter

|

Model |

OGD22 |

OGD55 |

OGD110 |

OGD250 |

|

Discharge capacity/ Discharge Pressure (m3/min/10-1Mpa) |

3.8/7-3.5/8-3/10 |

9.5/7-8.8/8-7.6/10 |

18/7-16.5/8-15/10 |

41/7-38/8-35/10 |

|

Air feed temperature(The degree of Celsius) |

Smaller same as Ambient temperature+15(The degree of Celsius) |

Smaller same as Ambient temperature+15(The degree of Celsius) |

Smaller same as Ambient temperature+15(The degree of Celsius) |

Smaller same as Ambient temperature+15(The degree of Celsius) |

|

Power(kw) |

22 |

55 |

110 |

250 |

|

Speed of running(r/min) |

2940 |

2970 |

2980 |

2980 |

|

Startup mode |

Planetary triangle startup. |

Planetary triangle startup. |

Planetary triangle startup. |

Planetary triangle startup. |

|

Power supply |

380V/50HZ |

380V/50HZ |

380V/50HZ |

380V/50HZ |

|

Drive mode |

Belt drive |

Mainframe is connected by coupling and motor directly. |

Mainframe is connected by coupling and motor directly. |

Mainframe is connected by coupling and motor directly. |

|

Oil content in air feed(ppm) |

3-5 |

3-5 |

3-5 |

3-5 |

|

External pipe aperture(in) |

R1 |

R1 3/4 |

DN80 |

DN125 |

|

Acoustics pressure level db(A) |

72 |

72 |

76 |

78 |

|

Compressor unit weight(kg) |

700 |

1450 |

2300 |

6000 |

|

Profile size (Length*Width*Height)(mm) |

1300*900*1400 |

2000*1200*1600 |

2800*1900*1800 |

3500*2500*2500 | |

|

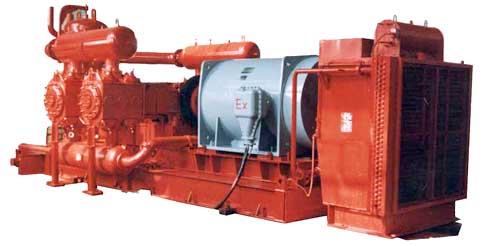

RDS serial gas compresso

|

|

RDS serial gas compressor unit is manufactured with reciprocating gas design and manufacturing technology of American DRESSER-RAND in combining with the actual situation of China and this plant,which has reached the advanced level of the domestic compressor unit and is in the same level as that of the compressor unit in foreign countries.

RDSA compressor is a updated product of RDS compressor. RDSB serial gas compressor is a kind of compressor with larger piston power, large power and wider operating conditions and applications developed on the basis of RDS and RDSA compressors. RDS serial compressors possess 2, 4 and 6 these three kinds of number of columns of frame, equipped with cylinders of more than 20 kinds of dimensions,through integration of various kinds of cylinders and adjustment of gaps,which can meet the requirements of different operating conditions from the user.

Power of RDS serial gas compressor is equipped according to the need of users, it can be diesel engine, motor and natural gas generator, etc.

Purpose:

RDS serial gas compressor is large power compressor with high speed and wide applications,used in petroleum, petro-chemistry, mine and others, compressed natural gas, nitrogen, air, nitrogen and hydrogen, carbon dioxide, propane and various kinds of gases. In natural gas industry, RDS gas compressor can be used for oil production, collection and transport of natural gas, air charging and filling, gas storage, stabilization of crude oil, recovery of hydrocarbon, desulfation and pressurization, gas treatment and others.

Technical feature:

RDS serial gas compressor has absorbed the latest advanced technology nationally and internationally, enjoying high bearing capacity and wide applicable operating conditions. This kind of compressor of symmetrical balanced and reciprocating piston changeable operating conditions possesses compact structure, excellent performance, economic and reliable use, convenient operation and maintenance etc.

(1) Designed and manufactured by adopting American DRESSER-RAND technology, the equivalent adopts API618 and API11P standards.

(2) Compressor with high rotation speed, small volume and light weight.

(3) Module serial products, designed with changeable operating conditions. It is optimized and formed with the imported advanced computer calculation procedure, can meet requirements of different users and operating conditions.

(4) Installation structure through prizing open, convenient for user installation, with lower installation cost.

(5) The connection of compressor and driver with the main prizing areas adopts grouting with special epoxy resin, which has reduced the vibration of the compressor set to the lowest level.

(6) Compressor set adopts PLC control system, with high degree of automation.. Its temperature, pressure and liquid level of oil, water and gas and others have realized automatic control and protection, thus ensuring the safe operation of the unit.

technical parameters:

|

Model of compressor |

2RDS |

4RDS |

2RDSA |

4RDSA |

2RDSB |

4RDSB |

6RDSB |

|

Number of columns of compressor |

2 |

4 |

2 |

4 |

2 |

4 |

6 |

|

Rated power(kw) |

900 |

1800 |

1300 |

2600 |

1300 |

2600 |

3900 |

|

Stroke(mm) |

140 |

140 |

140 |

140 |

152 |

152 |

152 |

|

Max. rotation speed(rpm) |

1000 |

1000 |

1200 |

1200 |

1200 |

1200 |

1200 |

|

Diameter of piston rod(mm) |

54 |

54 |

64 |

64 |

64 |

64 |

64 |

|

Max. piston power(KN) |

170 |

170 |

270 |

270 |

270 |

270 |

270 | |

|

Air compressor

|

|

No.3 Petroleum Machinery Plant has begun to manufacture compressor since plant setup, and developed 2V, 2W, WY, 1VF series piston air compressors, including WY-10/2.5 model air compressor and 2V-6.5/12 model air compressor ranking the product of substitute for imported commodity, which were awarded the title of State Technology Achievement Award in 1993 and high-grade quality product of the ministry and province respectively, as well as accessories of the 2W-12.5/8 model air compressor, such as geophysical prospecting vehicle driller.

Purpose:

Air compressor is widely used for petroleum mine, mining, petroleum and chemical industry, machinery manufacture etc.

Technical feature:

(1)Tight construe, high efficiency, low noise, stable and reliable operation, good cooling effect, low energy consummation and easy maintenance etc.

(2)Predominant preference and reasonable price, all preference indexes meet state normal, including certain adjacent international level indexes.

(3)The heart part is gas valve and used by reticulation valve.

Technical parameter(2W-12.5/8 air compressor)

|

Discharge capacity(m3/min) |

Single-stage compressor operates 16.5 |

|

Two¨Cstage compressor operates 12.5 |

|

Operating pressure(MPa) |

single¨Cstage compressor operates 0.25 |

|

Two¨Cstage compressor operates 0.8 |

|

Axle power (horsepower) |

115 |

|

Cylinder quanlity |

4 low pressure cylinders |

|

2 high pressure cylinders |

|

Cylinder diameter(mm) |

210 low pressure cylinders |

|

180 high pressure cylinders |

|

Piton stroke (mm) |

130 |

|

Rotation speed (r/min) |

870 |

|

Cooling mode |

Air cooling |

|

Drive mode |

Belt driver |

|

Lubrication mode |

Injection pump compulsively conveys lubrication oil and splash | |

|

|

|