|

Techinal proposal for Tar cleaning for Kazakhstan gas power project

1, the current conditions and tar removal demands

Blue carbon is a kind of coal made from superior grade of raw coal, which are made by middle temperature dry distillation.

During the dry distillation, high temperature gas will be evaporated and discharged through the roof of the oven. The amount of gas generated in the Kazakhstan blue carbon dry distillation project is 21000m3 / h. there are water content in the gas, containing a higher amount of tar, tar content is of 12-20 g/m3. The flue gas temperature is of 110 °C or slightly higher. The tar removal demand is that gas tar content is not higher than 40mg/Nm3 after tar removal process.

Kazakhstan blue carbon gas composition

|

Element of content |

unit |

content |

|

H2 |

% |

16.2-31.3 |

|

O2 |

% |

1.5-8.6 |

|

CH4 |

% |

5.6-8.2 |

|

N2 |

% |

34.4-49.3 |

|

CO |

% |

14.2-20.2 |

|

CO2 |

% |

1.5-7.5 |

|

H2S |

mg/m3 |

0.05-0.06 |

|

C2H4 |

mg/m3 |

5218.7 |

|

C3H8 |

mg/m3 |

3281.2-3770.8 |

|

C2H2 |

mg/m3 |

41.7-70.8 |

|

C3-C4 |

mg/m3 |

198-416 |

|

C2-C4 |

% |

0.2-0.5 |

|

C2-C6 |

% |

0.3-0.5 |

|

density |

kg/m3 |

0.844-0.983 |

|

Water content |

g/m3 |

3.6-4.5 |

|

Tar |

g/m3 |

12-20 |

|

Total |

m3/h |

21000 |

Based on the above gas content related data, if adopting of Electrical/ electrostatic Tar Trap method to execute tar removal, it is needed to check the gas composition and research gas burning explosion features. If the oxygen content ranges in a safe range, then electrical Tar Trap or electrical tar precipitator can be used as the main equipment for tar removal. In order to ensure that the tar content is not greater than 40mg / Nm3, then temperature cooling, preliminary removal, and fine removal processes will be applied in the project.

The initial program

According to the gas composition, tar and water content, and final demand of tar removal, and also referring other project tar removal technologies and results, it is decided that temperature cooling, preliminary removal, and fine removal processes will be applied in the project. The process is: Blue carbon roof the gas is cooled to 45 ° C by a standpipe type indirect water cooler, then go through a whirlwind/cyclone type Tar remover, and through a set of electrical Tar Trap to finish the first time fine tar removal. And then go through another set of electrical Tar Trap to finish the second time fine tar removal. Then gas will go to next stage. In this proposal, indirect cooling water can be recycled for repeated use, radiation of heat is of open and natural type. Equipments as pupms, water pool, piping, valves will be used.

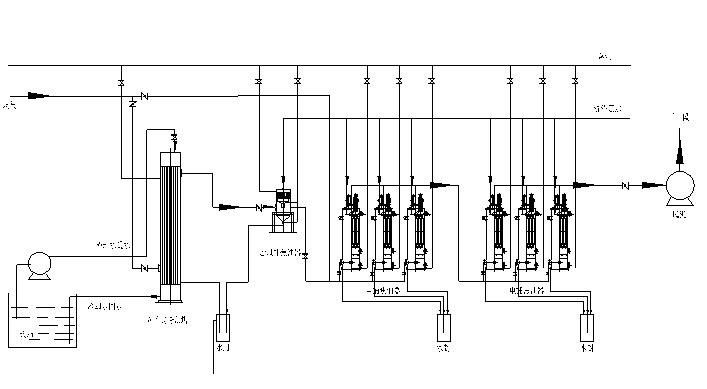

Tar Removal process flow diagram is as follows:

This program can effectively control the gas temperature, the use of indirect water-cooled heat exchanger has its advantages: it practically does increase the amount of gas and gas water content. The cyclone wind can capture tar fog droplets which are generated by the high-temperature condensation, this can reduce the tar content of gas, then secondly tar fine removal process can get the satisfactory tar removal results.

3. Major equipment technical parameters

(1) riser/ standpipe coolers and water supply

The riser cooler specifications: φ3.1 × 9.750m Quantity: 1 units

Processing volume: 21 000 m3 / h

Heat transfer area: 930m2

Working medium: the shell: coal Gas

Tube: circulating water

Operating temperature: the shell: 110 ° C to 45 ° C

Tube: 45 ° C ~ 28 ° C

Working pressure: the shell the: 0.017Mpa (meter)

Tube process: 0.4Mpa (meter)

Circulating pumps: H = 30m, Q = 200m3

(2). Cyclone Tar Remover: quantity: 1 set

Diameter x height: Φ3000x H-= 11 556

Processing volume: 21 000 m3 / h

Operating temperature: 25 ~ 40 ° C

Working pressure: 20Kpa

Working medium: coal Gas

Filler

(3) electrostatic tar Remover:

Specifications Model: FD76-II: quantity: 6 sets

Flue gas treatment flow: 8000 Nm3 / h

Effective flow area: 4.11m2

Inlet gas temperature: 20 ~ 50 ° C

Entrance/inlet tar concentration: 15g / Nm3

Dust concentration: 300mg / Nm3

Working efficiency: greater than or equal 98%

Diameter 2800mm height of 13.736m

Pprecipitating electrode:

Thickness: 2.5mm height of 5.50m

Type: Cellular

Size: regular hexagons on the edge distance of 250mm

Number of holes: 76

Corona wire:

Diameter: φ2.5mm

Quantity: 76

Electric tar removal resistance less than or equal 200Pa

Electrical parameters:

Rated operating voltage: 60KV

(4). Connection pipeline: DN900x8mm

(5) the electrical parts:

CS-III-type constant current source 300mA/60KV, quantity: 6 sets.

composing of high-voltage generator, constant current control cabinet.

China the most famous gas engine generator sets

For China gas engine generator sets or power plants, please click.

|