| Proportioning Scheme

The raw materials proportioning ratio, chemical composition of raw meal and clinker, clinker ratio and mineral composition are as follows:

|

/FONT> |

composition |

/FONT> |

Proportioning (%) |

|

/FONT> |

Raw Mix |

Clinker |

/FONT> |

dry |

wet |

|

L.O.I (%) |

36.02 |

/FONT> |

Limestone |

80.00 |

/FONT> |

|

SiO2 (%) |

13.81 |

22.31 |

Clay |

16.40 |

/FONT> |

|

Al2O3 (%) |

3.13 |

5.47 |

Iron ore |

1.50 |

/FONT> |

|

Fe2O3 (%) |

2.15 |

3.41 |

Sand |

2.10 |

/FONT> |

|

CaO (%) |

43.61 |

66.78 |

/FONT> |

/FONT> |

/FONT> |

|

MgO (%) |

0.77 |

1.18 |

/FONT> |

/FONT> |

/FONT> |

|

K2O (%) |

0.12 |

0.19 |

/FONT> |

/FONT> |

/FONT> |

|

Na2O (%) |

0.13 |

0.21 |

/FONT> |

/FONT> |

/FONT> |

|

SO3 (%) |

0.21 |

0.35 |

/FONT> |

/FONT> |

/FONT> |

|

Cl- (%) |

0.001 |

0.002 |

/FONT> |

/FONT> |

/FONT> |

|

Total (%) |

99.94 |

99.91 |

Total |

100.00 |

/FONT> |

|

IM |

1.46 |

1.60 |

/FONT> |

Coal |

|

|

SM |

2.62 |

2.50 |

Fuel (%) |

0.00 |

|

|

S/A |

4.41 |

4.08 |

Net value of fuel |

24253.3 |

kJ/kg |

|

KH |

0.971 |

0.901 |

Burning consumption |

3094.4 |

kJ/kg cl. |

|

LSF |

|

93.9 |

Fuel consumption |

131.5 |

kg fuel/t clinker |

|

HM |

/FONT> |

2.14 |

Ash in clinker(%) |

2.30 |

(%) |

|

C3S (%) |

/FONT> |

59.69 |

R. M. consumption |

1.5270 |

t R.M./t cl. |

|

C2S (%) |

/FONT> |

18.96 |

Moisture of raw mix |

|

(%) |

|

C3A (%) |

/FONT> |

8.73 |

Remark: |

|

C4AF (%) |

/FONT> |

10.38 |

|

|

Na2O+K2O (%) |

/FONT> |

0.41 |

|

|

1400°C liquid volume(%) /FONT> |

25.24 |

|

|

|

|

S/R |

1.43 |

|

/FONT> |

|

/FONT> |

|

E-SO3(g/100Kg clinker) /FONT> |

345.3 |

|

|

/FONT> |

Raw materials

|

|

Limestone |

Clay |

Iron ore |

Sand |

|

CaO (%) |

more than 48 |

|

|

|

|

MgO (%) |

less than 3 |

less than 3 |

|

|

|

K2O+Na2O (%) |

less than 0.6 |

less than 4.0 |

less than 4 |

less than 2 |

|

SO3 (%) |

less than 0.5 |

less than 1 |

less than 2 |

less than 1 |

|

Cl- (%) |

less than 0.015 |

|

SM |

|

2.5 - 3.5 |

|

more than 4 |

|

IM |

|

1.5 - 3.5 |

|

|

|

Fe2O3 (%) |

|

|

more than 45 |

|

|

Al2O3 (%) |

|

|

|

|

|

Moisture (%) |

less than 3 |

less than 15 |

less than 12 |

less than 8 |

|

Size (mm) |

less than or equal 1200 |

less than or equal 350 |

less than or equal 400 |

less than or equal 25 |

(4) The grindability (Bond Index) of the raw mix should be less than 10 kW.h/t.

(5) Burning Fuel coal

Net heat value as air dried more than 5800kcal/kg

Volatile as air dried more than 25%

Moisture as pulverized coal: less than 1%

Total sulfur as air dried: less than 1.5%

(6) The formulas of common clinker modules are the following:

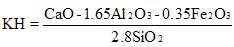

Lime saturation factor (KH):

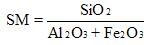

Silica ratio (SM):

Alumina ratio (IM):

Material Balance

|

/FONT>

Material

/FONT> |

Dry ratio |

Moisture |

Consumed amount for clinker (t/t) |

Material Balance (t) |

|

Dry |

Wet |

|

% |

/FONT>% |

Dry |

Wet |

Hour |

Day |

Year |

Hour |

Day |

Year |

|

limestone |

80.0 |

2 |

1233.97 |

1259.16 |

169.67 |

4072.11 |

1262353 |

173.13 |

4155.21 |

1288116 |

|

Clay |

16.4 |

12 |

252.96 |

287.46 |

34.78 |

834.78 |

258782 |

39.53 |

948.62 |

294071 |

|

Iron ore |

1.50 |

10 |

23.14 |

25.71 |

3.18 |

76.35 |

23669 |

3.53 |

84.84 |

26299 |

|

Sand |

2.10 |

8 |

32.39 |

35.21 |

4.45 |

106.89 |

33137 |

4.84 |

116.19 |

36018 |

|

Raw meal |

/FONT> |

/FONT> |

1542.47 |

/FONT> |

212.09 |

5090.13 |

1577942 |

/FONT> |

/FONT> |

/FONT> |

|

Clinker |

|

|

|

|

137.50 |

3300.00 |

1023000 |

|

|

|

|

Burning coal |

|

10 |

131.53 |

146.15 |

18.09 |

434.06 |

134557 |

20.10 |

482.28 |

149508 |

|

Gypsum |

/FONT> |

3 |

/FONT> |

/FONT> |

9.92 |

238.10 |

73810 |

10.23 |

245.46 |

76092 |

|

Slag |

/FONT> |

6 |

/FONT> |

/FONT> |

9.06 |

217.36 |

67381 |

9.63 |

231.23 |

71682 |

|

Trass |

/FONT> |

3 |

/FONT> |

/FONT> |

17.35 |

416.45 |

129100 |

17.89 |

429.33 |

133092 |

|

Clinker |

/FONT> |

/FONT> |

/FONT> |

/FONT> |

137.50 |

3300.00 |

1023000 |

/FONT> |

/FONT> |

/FONT> |

|

Cement(A) |

/FONT> |

/FONT> |

/FONT> |

/FONT> |

73.10 |

1754.39 |

543860 |

/FONT> |

/FONT> |

/FONT> |

|

Cement(B) |

/FONT> |

/FONT> |

/FONT> |

/FONT> |

99.21 |

2380.95 |

738095 |

/FONT> |

/FONT> |

/FONT> |

|

Cement (total) |

/FONT> |

/FONT> |

/FONT> |

172.31 |

4135.34 |

1281955 |

/FONT> |

/FONT> |

/FONT> |

Remarks:

(1) Kiln running rate: 310d/a;

(2) Material consumption: 1.527kg raw meal/kg clinker;

(3) Net heat value of Coal as air dried: 24253kJ/kg;

(4) Heat consumption: 740kcal/kg clinker (3094kJ/kg clinker);

(5) Burning fuel is bituminous coal.

(6) Cement proportioning

|

|

Cement(A) |

Cement(B) |

|

Clinker (%) |

95 |

70 |

|

Gypsum (%) |

5 |

5 |

|

Slag (%) |

|

10.00 |

|

Trass (%) |

|

15.00 |

Cement (A) is Portland cement and cement (B) is composite cement.

This is your e mail to us:

|

|

show details 27 Feb (6 days ago) |

|

Dear sir,

Commercial:

1. please provide your agreement with the buyer that your are his exclusive agency or consultant for the project consulting for EPC and financing.

2. after we getting your agreement with the buyer, we will evaluate the project and sign MoU or NCND with you.

3. providing technical requirement documents, feasibility study, environment impact study to us.

4. let the buyer complete the technical questionnaire for his projects.

5. MoU with the buyer as Exclusive EPC or financing arrangement advisor, we will arrange the financing if needed against gurantee. We intend to provide you with a Bank Guarantee against your financing arrangement,

We also provide:

1. xlpe, submarine, acsr cables, substation, and transmission projects, 2. GE or Siemens gas turbine plant and their spare parts, 3. hydro power plant 4. steam turbine plant, 5. gas engine generator, 6. hfo diesel generator, 7. Diesel generator, 8. power transformer, 9, Cement plant, 10, Waste heat recovry plants for cement and steel plants. |