| Company brief We have been engaged in the research and development and sales of organic fertilizer equipment and inorganic fertilizer equipment since starting business. It includes organic fertilizer production line, organic fertilizer granulator, bio-organic fertilizer production line, pig manure organic fertilizer production line, chicken manure organic fertilizer production line and various chemical inorganic fertilizer production line etc.

We have independently researched and innovated and developed bio-organic fertilizer technology for agricultural environmental protection technology development and waste recycling.

We have a high-quality staff team and CAD design technology center (organic fertilizer equipment research institute), and a perfect pre-sales and after-sales service level to provide customers with one-stop service of process design, equipment production, installation, commissioning and personnel training.

Our organic fertilizer equipment products have covered all provinces and cities nationwide, and a large number of organic fertilizer production line products have been exported to global countries. The chairman of our company, together with all the staff, warmly welcomes new and old customers to call, write or come to the company to visit, guide and negotiate business with the principle of stable quality and reputation first.

Major business: ·Organic inorganic compound fertilizer production line of 10,000 - 200,000 tons per year ·Compound fertilizer production line of 30,000-200,000 tons per year ·Complete organic fertilizer production line of 10,000-120,000 tons per year ·BB fertilizer production line of 10,000-200,000 ton per year    If you want to invest in organic fertilizer production projects, please contact with us . Our factory has a professional planning service team to complete the preliminary design and infrastructure work for you. To provide you with satisfactory service is our aim.

Important information of quotation Date | 04/12/2024 | Total machines | 58 sets | Total power | 776.9kw | Delivery time | 35-50 days after received the payment. | Voltage | 380V, 50HZ, 3 Phase. |

Capacity 20-25 tons per hour of organic fertilizer production line NO. | Name | Description | Qty (set) | Picture | 1 | Rotating disc compost turning machine | 1.model:22m, power�?/span>30+2.2+2.2+2.2+2.2+4=42.8kw 2. Equipment span 22 meters 3.Trough depth 2 meters 4. Turning lift 1.5-2 meters 5. The frequency conversion motor of the main traveling frame is 2.2kw×2. (Full copper core) Frequency variable speed brake three-phase asynchronous motor. 6. Turning sub-frame variable frequency motor 2.2kw×2, (all copper core) frequency variable speed brake three-phase asynchronous motor 7. Turning impeller main motor 30kw, full copper core 8. Contains control cabinet and remote control. 9. The electrical appliance is equipped with a travel switch, which can automatically turn over and shift. 10. The girder traveling and flipping sports cars are all controlled by frequency converters. 11. The impeller blades are made of manganese steel. 12. The girders are welded with 8mm steel plates. (550X900) 13. Install a frequency converter on the flipping motor. Adjustable flipping speed 14. The reducer adopts K series heavy-duty gear reducer 15. Hydraulic lift 4kw (all copper core). 16. Total weight of turning machine: about 28 tons 17.function:turning and breaking the block form raw materials, increase the ferment effect, reduce the fermentation time. | 1 |

| 2 | Fermentation tank aeration system | 1. The motor is 11kw*4=44kw. 2. The fan adopts high-pressure Roots blower. 3. The main pipe adopts DN100. 4. The ground channel pipe adopts DN60. 5. Use automatic oxygen supply system. | 4 |

| 3 | Workshop internal deodorization system | 1. The model is Φ1.5X6,motor:5.5+1.8=7.3kw. 2.The spray tower is made of PP material. 3. Equipped with photooxygen and activated carbon deodorizer. 4. Including the connecting pipe between the spray tower and the deodorizer. (excluding internal pipes in the workshop) | 1 |

| 4 | Feeding bin of loader | 1.model:3*4m, motor: 4+3=7kw. 2.Performance: The organic fertilizer forklift feeder is a bulk material conveying equipment with strong adaptability, adjustable conveying capacity and the function of continuously and evenly conveying various materials. 3. Silo volume: 8M3 4. Effective length of conveyor: 5M 5. Transmission form: belt, gear 6. The frame is welded with 14# square tube. 7. Contains stirring/dispersing device. 8. Including discharging belt conveyor B800X5 meters. | 1 |

| 5 | Vertical crusher | 1. The model is :Ø1500.motor is :75kw 2. The crusher shell is welded with 14mm steel plate. 3. The frame is welded with 14# standard channel steel. 4. The chain is made of high-strength alloy chain, which is durable and wear-resistant. 5. The motor adopts Shandong Xiaguang national standard all-copper core motor. 6. The discharge port adopts an extended closing design. 7. The space at the bottom of the frame can be used to place a conveyor, making it easy to receive materials. | 1 |

| 6 | Rotary sieving machine | 1.model:Ø1.8*8m, motor:11kw. 2.frame is welding from 14# channel steel. 3.screen is made from 304# stainless steel. 4.steel are 6mm standard carbon steel. 5.gear reducer - JZQ400. 6.copper core motor. 7.Install vibration device to prevent sticking net. 8.function: raw materials size grading by the different hole in screen, correct size go to next machine, incorrect go back to crusher. | 1 |

| 7 | Automatic batching system(4bins) | 1.model:B650X2,motot:2.2*4=8.8kw 2. The frame is welded with 20# standard channel steel 3. 5 belt machine measurement. Belt for skirt belt. 4. According to the formula line ingredients, automatic computer control. 5. Equipped with industrial computer, PLC control, including touch screen, automatic control system. 6. Including the thickness of the bin board 4mm. Including bin support. 7. 7.the machine can automatically mix according to s your settings. 8.according to your raw materials kinds to decide Use how many bins. | 1 |

| 8 | Double Shaft continuous mixer | 1.model:1000*4000, motor: 30kw. 2.frame is welding from 14# channel steel. 3.Housing plate thickness 10mm standard carbon steel. 4.The upper part is equipped with dustproof cover plate. 5.gear reducer: JZQ500. 6.copper core motor. 7.function: uniform mixing and stirring various raw materials. | 1 |

| 9 | Three in one granulator | 1.model:Ø2.2X8,power:30kw+75kw=105kw 2. The outer drum body and the inner stirring tooth device also have the rounding function. 3. The built-in inlaid tooth cutter head has the effect of forced granulation. 4. Set a reasonable distance between the cylinder wall and the tooth stirring device. 5. The outer cylinder and the internal stirring device rotate in opposite directions to accelerate granulation and improve the granulation rate. 6. The feeding and discharging are closed to avoid dust during the granulation process. 7.The bottom frame of the granulator is made of thick materials, supported in many places, and the materials are densely used to ensure the stability of the machine. 8. The rolling belt, ring gear, and tug are unified into steel castings, which are corrosion-resistant and wear-resistant, and are suitable for high-intensity production operations. 9. The stirring teeth are inlaid-welded and have a long service life. 10. Use the national standard emission reduction machine JZQ650. 11. Using national standard all-copper core motor, after-sales guarantee. | 1 |

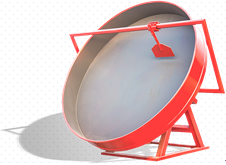

| 10 | Disc granulator | 1.model:Ø3600,motor:22kw 2. 12mm standard carbon steel plate is used for the disc body. 3. 14mm standard carbon steel plate at the bottom of the disc. 4. Frame 16# standard channel steel welding. 5. Reducer JZQ500. 6. The motor adopts national standard copper wire. 7.function:make the granules second time granulation,imporve the granulaton rate. | 1 |

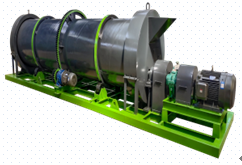

| 11 | Rotary drying machine | 1.model:Ø2.4*24m, motor:55kw. 2.shell thickness - 18mm,lifting plate:12mm 3.seal device of two side of dryer are made from 10mm steel plate. 4.gear ring and riding wheel are all steel castings. 5.gear reducer - JZQ850. 6.copper core motor. 7.function: drying and reduce the moisture/humidity in granules by high temp. | 1 |

| 12 | Burner | 1.Heat:2,400,000 calories,power:1.5kw. 1. The burner can burn methanol, natural gas and coal gas. 2. This machine is equipped with automatic temperature control function. 3. The electrical control system adopts Siemens. 4.if you burn biomass,coal to supply hot source,you can tell me,I can change this machine. | 1 |

| 13 | Cyclone dust collector | 1.model:2200*4500. 2.The plate thickness is welded with 5mm steel plate. 3.The cyclone duct adopts Φ800. | 1 |

| 14 | Draught fan | 1.model:4-72-12C, motor: 45kw. 2.application:the heat in the hot blast heat is effectively pumped into the raw material dryer for best results. 3.the fan is equipped with an automatic control air volume system, and the dryer is used together. 4.copper core motor. 5.function: provide wind energy to dust extractor and drying machine. | 1 |

| 15 | Rotary drying machine | 1.model:Ø2.2*22m, motor:30kw. 2.shell thickness - 16mm,lifting plate:10mm 3.seal device of two side of dryer are made from 8mm steel plate. 4.gear ring and riding wheel are all steel castings. 5.gear reducer - JZQ650. 6.copper core motor. 7.function: drying and reduce the moisture/humidity in granules by high temp. | 1 |

| 16 | Burner | 1.Heat:2,400,000 calories,power:1.5kw. 1. The burner can burn methanol, natural gas and coal gas. 2. This machine is equipped with automatic temperature control function. 3. The electrical control system adopts Siemens. 4.if you burn biomass,coal to supply hot source,you can tell me,I can change this machine. | 1 |

| 17 | Cyclone dust collector | 1.model:2200*4500. 2.The plate thickness is welded with 5mm steel plate. 3.The cyclone duct adopts Φ800. | 1 |

| 18 | Draught fan | 1.model:4-72-10C, motor: 30kw. 2.application:the heat in the hot blast heat is effectively pumped into the raw material dryer for best results. 3.the fan is equipped with an automatic control air volume system, and the dryer is used together. 4.copper core motor. 5.function: provide wind energy to dust extractor and drying machine. | 1 |

| 19 | Rotary sieving machine | 1.model:Ø1.8*8m, motor:11kw. 2.frame is welding from 14# channel steel. 3.screen is made from 304# stainless steel. 4.steel are 6mm standard carbon steel. 5.gear reducer - JZQ400. 6.copper core motor. 7.function: raw materials size grading by the different hole in screen, correct size go to next machine, incorrect go back to crusher. | 1 |

| 20 | Rotary cooling machine | 1.model:Ø2.2*22m, motor:30kw. 2.shell thickness - 16mm.lifting plate:10mm 3.seal device of two side of dryer are made from 8mm steel plate. 4.gear ring and riding wheel are all steel castings. 5.gear reducer - JZQ650. 6.copper wire motor. 7.function: reduce the temp of granule by nature air. | 1 |

| 21 | Cyclone dust collector | 1.model:2000*2500. 2.The plate thickness is welded with 5mm steel plate. 3.The cyclone duct adopts Φ800. | 1 |

| 22 | Draught fan | 1.model:4-72-10C, motor: 30kw. 2.application:the heat in the hot blast heat is effectively pumped into the raw material dryer for best results. 3.the fan is equipped with an automatic control air volume system, and the dryer is used together. 4.copper core motor. 5.function: provide wind energy to dust extractor and drying machine. | 1 |

| 23 | rotary sieving machine | 1.model:Ø1.8*8m, motor:11kw. 2.frame is welding from 14# channel steel. 3.screen is made from 304 stainless steel. 4.steel are 6mm standard carbon steel. 5.gear reducer - JZQ400. 6.copper core motor. 7.function: raw materials size grading by the different hole in screen, correct size go to next machine, incorrect go back to crusher. | 1 |

| 24 | Return materials crusher | 1. model:Ø1000,motor:37kw. 2.The frame is welded with 14# channel steel. 3. Cylinder plate thickness 12mm. 4. The chain is made of high strength steel. 5. The motor adopts national standard copper wire. 6.function:crush the return back materials. | 1 |

| 25 | Granule coated machine | 1:model:Ø1.8*6m, motor:15kw. 2:diameter of shell: 1,800mm, length of shell: 6,000mm. 3:Roller belt, gear ring and tug are cast steel parts. 4:thickness of shell: 14mm. 5:gear reducer: JZQ400. 6:function: add colouring / anti-caking agent in granule, and forming a film on the surface of granule to protect no reaction between granules. | 1 |

| 26 | Liquid agent storage tank | 1:model:Φ1000, motor: 0.75+1.5=2.25kw. 2:max diameter: 1,000mm. 3:thickness of shell: 8mm. 4:Including heating apparatus, mixing device, gear pump, and spray-head. 5:function:liquid colouring / anti-caking agent storage tank with spray device. | 1 |

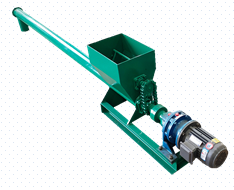

| 27 | Powder screw conveyor | 1:model: Φ108*3m, motor: 0.75kw. 2:diameter: 108mm, length: 3,000mm. 3:thickness of shell: 3mm. 4:with an adjustment speed motor. 5:function: transport and spray the powder colouring / anti-caking agent. | 1 |

| 28 | Double silos automatic packing machine | 1.model:DCS-50-2Y,motor:3.5*2=9kw 2.The main machine adopts a three-speed feeding structure of fast, medium and slow. 3. The parts in contact with materials are made of 304 stainless steel. 4. The frame is welded to 60# standard square tube. 5. The sewing machine adopts Hebei Youtian brand. 6. Contains silo and bottom conveyor. 7. The sewing machine head is upgraded to automatic thread trimming, which saves labor and is more efficient. 8,include air compressor. 8. Purpose: Automatic packaging of finished particles. | 2 |

| 29 | Robot palletizer | 1. model:180,motor:5kw 2. Robot host: Eston 180, articulated, degrees of freedom: four axes, Working area: Width 1,800 mm, depth 1,600 mm, height 2,200 mm, load 180kg. Robot control system: Eston special control system. Robot base: The main body is made of 30mm steel plate, with a 150X100 weighted rectangular tube welded frame. Robot fixture: Yadeco cylinder 50x50, Japanese Omron sensor switch, special bag gripper. Grabbing position: Line length 1 meter, roller width 800mm. Carbon steel frame, galvanized round roller. Robot guardrail: Japanese Omron sensor switch | 1 |

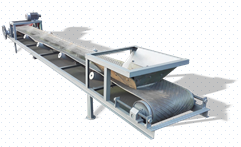

| 30 | Belt conveyor | 1.model:B800*10m, motor: 5.5kw*20=110kw. 2.frame is welding from 16# channel steel . 3.the carrier roller is Φ89X305 heavy duty idler. 4.herringbone tape - 5tier. 5.transmission mode is synchronous gear transmission. 6.copper core motor. 7.function:transport correct size granule. | 21 |  | 31 | Production line control cabinet | 1. Automatically control the entire production operation status. 2. Electrical components are of Chint or Delixi brand. 2. Equipped with a central control computer, which will alarm if the unit fails. 3. Equipped with thermal relay and single power-off switch. | 4 |  |

|