| Download Organic fertilizer turns waste into treasure.pdf Organic fertilizer turns waste into treasureWhen making organic fertilizer, we usually ask a few questions: Where do the raw materials come from? How to make organic fertilizer? What is the profit margin of organic fertilizer? How to find sales channels for organic fertilizer?

Let’s analyze it from these aspects. 1. Where do the raw materials come from?1.1 Organic fertilizer raw materials are available everywhere, low cost and easy to collect

| Type of raw materials | Raw material name | Picture | | Animal Husbandry Waste | Livestock and poultry excrement, livestock and poultry kennel bedding (plant-based), waste feed |

| | Plantation waste | Grain, wheat, potato, bean, oilseed, horticultural and other crop straw, forest and grass waste |

| | Processing waste | Bran, rice husk, rapeseed cake, soybean cake, peanut cake, sesame cake, sunflower cake, cottonseed cake, tea seed cake and other by-products from the processing of planting |

| | natural raw materials | Peat, lignite, etc. |

|

1.2 Why can these raw materials be made into organic fertilizers?First, the first indicator to consider in organic fertilizer is the content of organic matter, please see the table below: | Raw materials | Organic matter content | Raw materials | Organic matter content |

|---|

| chicken manure | 24-27% | corn straw | 30% | | Pig manure | 15% | wheat straw | 46.3% | | Cow dung | 14.5% | rice straw | 40% | | horse manure | 21% | wheat bran | 45% | | bird manure | 25.5% | Mushroom residue | 30-45% |

Second, look at the carbon-nitrogen ratio. The normal carbon-nitrogen ratio is generally between 20-30. Feces generally have a high nitrogen content but a low carbon-nitrogen ratio. Straw has a high carbon-nitrogen ratio but a low nitrogen content. A carbon-nitrogen ratio that is too high or too low is not conducive to fermentation, so a mixture of feces + straw is needed to adjust the carbon-nitrogen ratio. 2. What kind of organic fertilizer is made? How to make organic fertilizer?How to make manure into organic fertilizer?

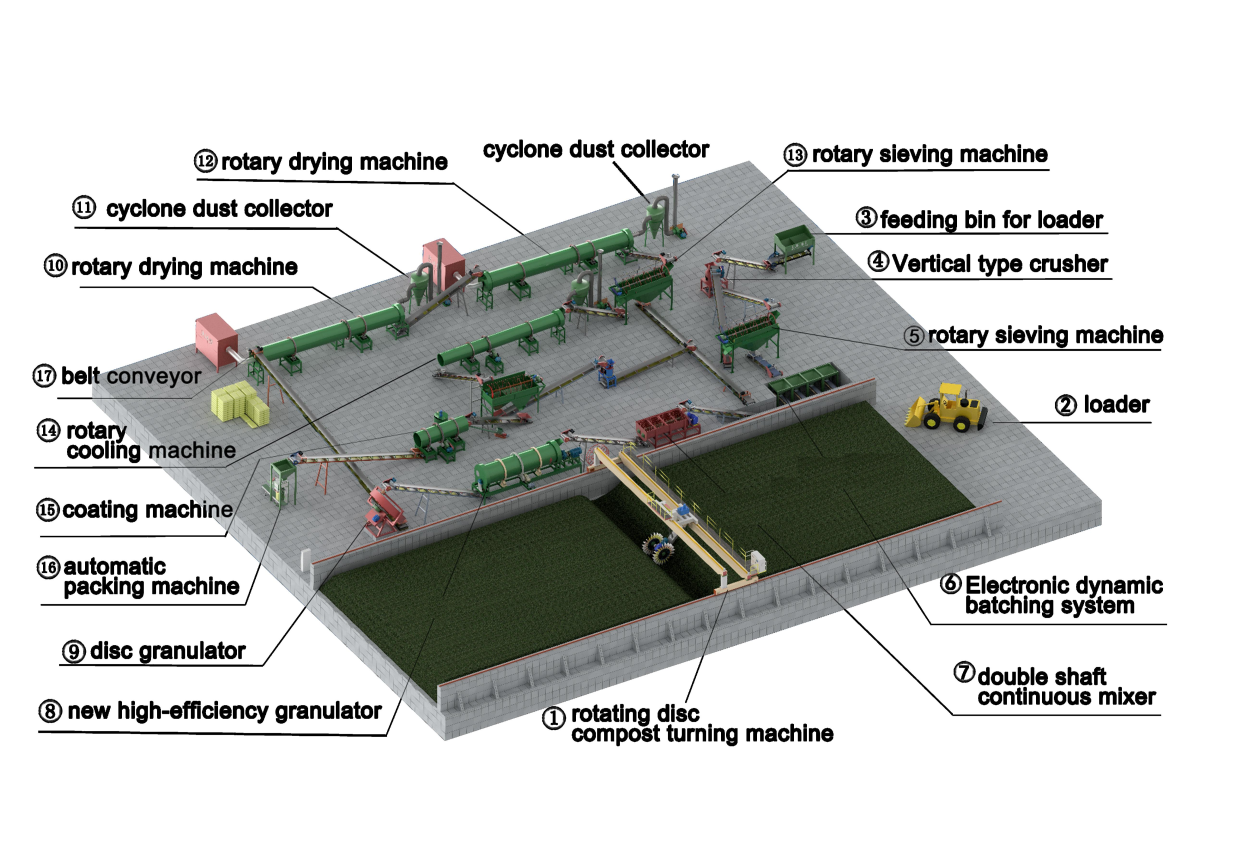

Fermentation �?ferment the material to maturity �?Feed hopper �?Automatic batching (Add nitrogen, phosphorus, potassium or other materials, precise proportion) �?Screening (Impurities or lumps) �?Crushing (crushing block materials) �?nbsp;

Mixing �?Granulator �?Screening �?Cooler �?Dryer machine �?Automatic Packing machine Flow chart

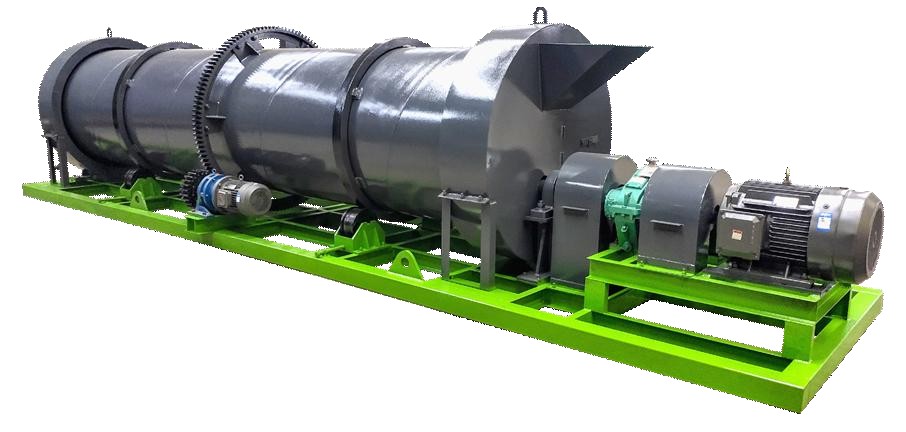

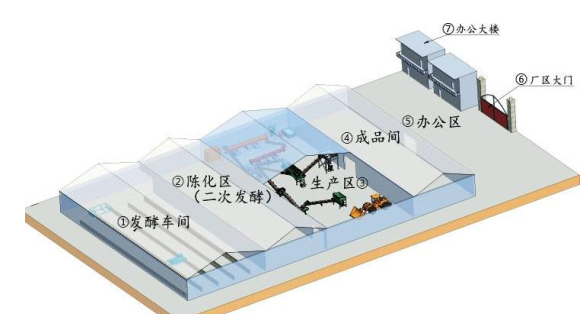

1 belt conveyor �?2 loader �?3 feeding bin for loader �?4 Vertical type crusher �?5 rotary sieving machine �?6 continuous mixer �?7 double shaft mixing system �?8 new high-efficiency granulator �?9 disc granulator �?10 rotary drying machine �?11 cyclone dust collector �?12 cooling machine �?13 rotary drying machine �?14 cyclone dust collector �?15 coating machine 3. Ten reasons to choose Our PartnerAbsolutely the manufacturer! You need to see the physical factory and processing equipment. Some sales companies falsely claim to be manufacturers, so you must keep your eyes open. In 1995, Our Partner Machinery Factory was upgraded to Zhengzhou. in 2009, with the same legal person and location. (Build new office, New Gate, Improve again) Warehouse development: 2 warehouse at first �?Increase 4 warehouse �?Increase 6 warehouse Between 1995 and 2023, products were continuously updated and product manuals were continuously updated. Product range: 10,000-200,000 tons/year compound fertilizer granulation complete sets of equipment, organic fertilizer equipment, compound fertilizer equipment Technical support! Buying equipment is not just about buying equipment, but also about production process and technology. Quality Journey: 2019 Quality Journey �?2020 Love Service �?2021 Quality Journey �?2022 Quality Journey with the service concept "Smile on the face, service in the heart" Technical team: 1 chief technical engineer, 1 technical section chief, and 4 core technical personnel, responsible for the research and development of equipment technology and new products. Senior fertilizer formulator: Wang Chuxin (male, born in May 23, 1989), senior professional direction, with 72 training hours, passed the assessment, certificate number NK20NK0130005115, issued on November 25, 2022, can assist in fertilizer formulation. We provide free trial service. Customized equipment: the equipment model can be customized according to your factory site and actual requirements. Free site design, and design a fertilizer production plan suitable for your company based on the site and requirements. (Including �?fermentation workshop, �?aging fermentation production area, �?factory gate, �?finished product warehouse, �?office area, �?office building)

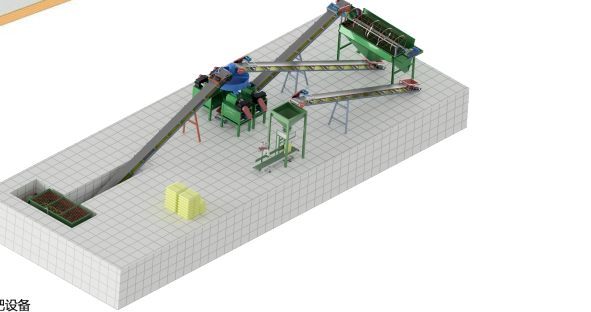

We provide free trial service:

Raw material Machine processing Discharging

Customized equipment: the equipment model can be customized according to your factory site and actual requirements.

Free site design, and design a fertilizer production plan suitable for your company based on the site and requirements

|