|

Engine |

|

|

Model |

Shangchai C6121ZG72B |

|

Type |

|

|

water-cooled, single-row, vertical, 4-stroke-cycle, turbo-charged |

|

Rated revolution (rpm) |

1900rpm |

|

Rated power (KW) |

131kw |

|

Rated fuel consumption (g/kw.h) |

215 |

|

Max. torque (N.m/rpm) |

770/1400 |

|

Starting Mode |

24V electric starting |

|

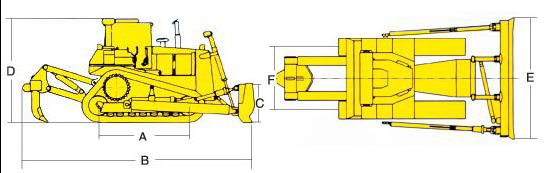

Main Specification |

|

Operating Weight (kg) |

16200kg |

|

Ripper weight (kg) |

1600kg |

|

Ground pressure(kPa) |

55.23kPa |

|

Min. ground clearance (mm) |

445mm |

|

Grade ability (0) |

300 |

|

Ground contact length of track(mm) |

2667 |

|

Center distance of track (mm) |

1880mm |

|

Max. tractive force |

145KN |

|

Dozing operation rate(moving distance 40m) |

320m3/h |

|

Theory travel speed (km/h) |

|

|

1st gear forward 0-4.0 |

1st gear backward 0-4.8 |

|

2nd gear forward 0-6.9 |

2nd gear backward 0-8.4 |

|

3rd gear forward 0-10.9 |

3rd gear backward 0-12.9 |

|

Power transmitting system |

|

|

Torque converter |

Single-stage, single-phase, 3-element |

|

Transmission |

Planetary gear, multi-disc clutch, hydraulic engaged, forced lubrication |

|

Main drive |

Spiral bevel gear, single-stage speed reduction, splash lubrication |

|

Steering clutch |

Wet, multi-disc, spring loaded, hydraulically separated, hydraulic control |

|

Steering brake |

Oil-cooled, hydraulically-boosted two direction contracting band brakes with foot pedal control |

|

Final drive |

Double spur gear reduction |

|

Undercarriage system |

|

|

Type |

|

|

Swing type of sprayed beam, suspended structure of equalizer bar |

|

Number of carrier rollers (each side) |

2 |

|

Number of track rollers (each side) |

7 |

|

Track type |

Assembled single-grouser shoes(39/each side) |

|

Width of track shoes(Standard) |

560mm |

|

Caterpillar track Pitch |

203mm |

|

Implement hydraulic system |

|

Max. pressure |

15.5Mpa |

|

Pump type |

Double gear pump |

|

Discharge |

178L/min |

|

Control valve type |

Sliding valve |

|

Bore of the working cylinder X number |

100mm x 1 |

|

Bore X NO. (Tilting cylinder) |

1500mm x 1 |

|

ROPS/FOPS with air conditioner cab |

|

|

The cab is hexagonal thin wall box-type structure. Glass is mounted at six sides with wide view area. Pulling and pushing glass is installed at back side. Air conditioner adapts a type of cooling and heating. The structure of Rop/FOPS is rigid. It can protect the driver efficiently when the bulldozer is in special condition. |

|

Working equipment |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|