|

Drawings

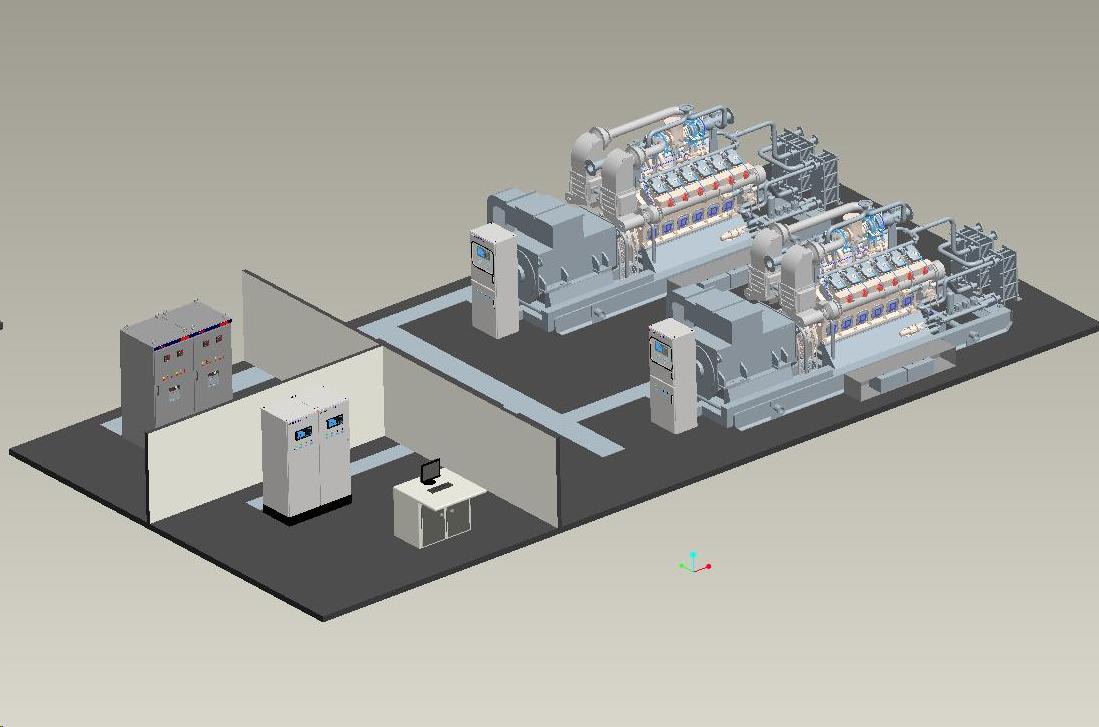

Click here to view the Outline drawing for 600kW Gas engine Power Plant 14/6 2013

Click here to view the Outline drawing for 600kW Gas engine Power Plant 14/6 2013

Click here to view the Foundation drawing for 600kW Gas Power Plant14/6 2013

Technical Proposal

According to the client’s gas condition, 600kW syngas Genset to be selected

NG: 2,500nm3/hr COG: 9,700-11,500 nm3/hr

|

NG |

COG |

component |

|

86.67 |

21.63 |

CH4 |

|

0.00 |

60.46 |

H2 |

|

1.14 |

2.82 |

CO2 |

|

0.00 |

0.00 |

O2 |

|

5.99 |

4.00 |

N2 |

|

0.00 |

0.00 |

H2O |

|

0.00 |

8.82 |

CO |

|

3.12 |

0.31 |

C2H6 |

|

0.00 |

1.88 |

C2H4 |

|

1.50 |

0.00 |

C2H2 |

|

1.21 |

0.00 |

C3H8 |

|

0.00 |

0.08 |

C3H6 |

|

0.00 |

0.00 |

N-C4H10 |

|

0.24 |

0.00 |

Iso_C4H10 |

|

0.03 |

0.00 |

N-C5H12 |

|

0.10 |

0.00 |

Iso-C5H12 |

|

100.0 |

100.0 |

sum |

|

2,500 |

9,700-11,500 |

Capacity (m3/hr) |

|

Genset model |

600GF-TEM2 |

|

Engine model |

T12V190 |

|

Alternator model |

1FC6 457-6LA42-Z |

|

(kW) Rated Power |

600 |

|

(A) Rated current |

1083 |

|

(V) Rated voltage |

400 |

|

COSΦ Rated power factor |

0.8 (lagging) |

|

(Hz)Frequency |

50 |

|

(MJ/kWh)

Fuel consumption |

9.88 |

|

(g/kWh) Lube oil consumption |

‘≤0.85 |

|

Switch on method |

24VDC |

|

Starting Mode |

Automatic |

|

Voltage control method |

Automatic |

|

Speed regulation method |

Electronic governor |

|

Excitation way |

Brushless |

|

Wiring method |

Three-phase,four-wire system or Three-phase, three-wire system |

|

Cooling method |

Closed type |

|

Connection type |

Flexible couping connection |

|

Dimension, L×W×H(mm) |

5433×1970×2700 |

|

(kg) Weight |

10750 |

|

(h) Overhaul period |

30000 |

|

Model of engine |

T12V190 |

|

Configuration and type |

four stork, direct injection fuel system |

|

Cylinder arrangement |

V type 60°included angle |

|

No. of cylinder |

12 |

|

(L) Total displacement, L |

71.45 |

|

Rated speed(r/min) |

1000 |

|

Idle speed(r/min) |

600 |

|

Rated power(kW) |

650 |

|

Fuel consumption(MJ/kWh) |

9.5 |

|

Lube oil consumption(g/kWh) |

‘≤0.8 |

|

Jacket water temp(°C) |

‘≤85 |

|

(°C) Lube oil temp(°C) |

‘≤90 |

|

Lube oil pressure in oil main line(kPa) |

400~800 |

|

Lube oil pressure in turbocharger (kPa) |

200~400 |

|

(%) Stable speed drop |

0~5 adjustable |

|

Lubricating system |

Pressure and splash lubrication |

|

Ignition method |

Spark plug ignition |

|

Starting method |

24VDC motor |

|

Direction of rotation |

Clock-Wise (viewed from the front) |

|

|

Electronic Governor |

|

|

|

|

Output way |

flywheel output |

|

Emission standard |

Eu 3 |

|

Alternator model |

1FC6 457-6LA42-Z |

|

Output power(kVA) |

750 |

|

(r/min)Rated speed |

1000 |

|

(V) Rated voltage |

400 |

|

(A) Rated current |

1083 |

|

(Hz) Frequency |

50 |

|

Power factor(lag) |

0.8 |

|

Insulation Clause |

F |

|

Direction of rotation |

Clock-Wise(Facing flywheel) |

|

Protection Clause |

IP23 |

|

Cooling Method |

Air cooling |

3. Systems introduction of project

3.1 Gas intake system

3.2 Cooling cycle system

The cooling system of 600GFZ1-Pwt-ESM3 genset was closed cycle, the advantages of closed cycle as followings: simple structure, less investment, reduce the thermal load of engine effectively, extend the life of engine parts.

Cooling system adopt the fan cooler to cooling, recycle water adopt softened water, and the water hardness: 0.7~5.3me/l, PH value: 6~8.5, gensets are divided into high and low temperature cooling cycle system. inlet water temperature of gensets high temperature recycle water : 60°C~70°C, outlet water temperature: 70°C~80°C

Flowchart on internal closed cycle of closed genset:

Schematic diagram on external interface of gensets:

3.3 Electrical system

The output voltage of gas gensets: 400V, connect to circuit breaker cabinet of the genset by cables, through the circuit breaker cabinet to output.

Electric switch, solenoid valve, lighting in generator room are adopt explosion proof type.

3.4 Protection system of gensets

The protection can be come true as: high temperature of cylinder, high exhaust temperature, overspeed, high temperature of the cooling water, high temperature of the oil, low oil pressure, high differential pressure of oil, low water level, low oil level, the failure of horizontal multi-fan water tank, the failure of sensors, winding temperature of gensets, high temperature of the gensets bearing, overload, overcurrent, short circuit, reverse-power, underfrequency and overfrequency, undervoltage and overvoltage, too high or too low of the battery voltage.

The genset adopt TEM2 automatic control system, come true the collect, display, record and print function of the genset’s all parameters(temperature of cylinder, exhaust temperature, water temperature, oil temperature, oil pressure, rotational speed, power, voltage, current, power factor, frequency, Accumulative total of generating capacity, Accumulative total of genset’s running time etc.), this system is most advanced automatic control system in china.

the control system can accomplish One-Touch startup, Automate synchronization, automatic regulation the load, protect and control the gas genset with failures: overspeed, low oil pressure, high oil temperature, high water temperature, high temperature of cylinder, reverse-power, underfrequency, overcurrent and so on.

4. Introduction of SD

SD-the largest professional gas eingine manufacturer in China. The company was founded in 1978 and is the earliest internal combustion gas engine manufacturer in China. With more than 30 years experience, SD has become the service expert in distributive energy filed covering natural gas, producer gas, gas, coal seam gas, coking gas, etc.

The core business of SD is research& manufacturer of gas engines, now the main business has covered the following industries:

1. Comprehensive utilization of coal mine gas

SD can realize coal mine gas zero emission for customers. Customer can choose different utilization method for different CH4 concentration (0.25%~100%) coal mine gas.

2. Renewable energy industry

SD has successfully make use of wood, straws, rice husk, cow dung and other renewable energy through gasification, carbonization and anaerobic digestion etc. Making use of energy scientifically and developing recycle economy.

3. Gas power generation industry

Making use of coke oven gas, producer gas and oil shale gas, etc. to set up power plants. SD has set up professional design & consulting, operating & management company, so as to provide turn-key service to customers. SD has become an integrated company engaged in power plant design, equipment supply, power plant construction and operation, etc.

4. Land & marine diesel power industry

The diesel engines manufactured by SD are widely used in power generation, drilling and marine industry. With the features of stable operation and high efficiency, the diesel engine has been widely recognized by customers.

5.Petroleum equipment and oil pipe industry

SD can also provide workover rig, special oil pipe, drilling rigs and oil production equipment, etc. to customers.

6. Overhaul & industry

SD can make overhaul of diesel engine, gas engine and generator, upgrade or renovating engines according to customer’s requirement.

7. Alternator & electrical control industry

The TF series three-phase A.C. synchronous alternator which developed by SD Group independently, can be equipped with internal combustion engine, gas turbine and other prime motors to form generator set, providing power generation equipment for land & marine use, offshore platform. SD can also provide high & low voltage equipment, CDM monitoring system, PLC monitoring system and background management system to customers.

Question: Also can you send any proposal I discuss with client for confirmation?

A: you should confirm with your client the following:

1. Flow and composition of the gas.

2. The stable result of the gas after gas treatment from oven, the residual content of tar, powder, Sulfur and sulfides, benzene, naphthalene amines in the gas after treatment.

3. are the sets to be lined together and connected with grid or not, electric systme data as voltage, frequency.

OFFER

Our producer has developed gas engine generator set with fuel of high content of Hydrogen gas, esp. for the application for Coke oven gas, and the hydrogen gas content can be as high as 50%-100%, so no need to reduce the content of Hydrogen, and also no need to supplement with natural gas, this will save your solution a lot of investment.

Our quotation on the coke oven gas gas engine generator set of 12V190-1000rpm-600kW:

FOB china: 450USD/kw.

Quotation code 176120130605

From your gas flow of coke oven and natural gas, you can generate around 25mw.

China the most famous gas engine generator sets

China’s large gas generating set by CNPC manufacturing For China gas engine generator sets or power plants, please click.

|