1.2 MW gasification power generation, gas supply system

(1) Gasification reaction of biomass

Bamboo access to gasifier through Feeder. Under high-temperature, recycling and heating materials, Palm husk in gasifier meet air accessing from bottom so that pyrogenation& gasification reaction occurred, and bamboo converted into fuel gas . the element of fuel gas: CO’┐Į?/SPAN>HB2B’┐Į?/SPAN>CHB4B etc. Calorific value: 1450kcal/ mP3 P approximately. Moreover, including a little tar .

Composition of fuel gas produced by olive pomace under normal circumstances (see table 1)

Table 1 available composition and heat value of fuel gas

|

CO |

CHB4B |

CBnBHBmB |

HB2B |

’┐Į?/SPAN> LHV’┐Į?/SPAN> |

|

% |

% |

% |

% |

kcal/NmP3P |

|

16.18 |

4.83 |

1.75 |

9.13 |

1446 |

(2)Fuel gas Purification

Through innovated fuel gas purification technology, dust, tar included in fuel gas is effectively treated and collect to completely achieve the demand of internal combustion. Meanwhile, Tar exhaust water is treated through biochemical treatment technology, achieving to recycle exhaust water and achieving the purpose of discharge zero pollution.

(3) Fuel gas power generation

3 units improved 500kw gas power generation engine are connected to generate electricity. Output voltage: 400V, 50HZ. The voltage will be enhanced to meet grid-tied demand by transformer.

(4) CHP system

Exhaust gas from internal combustion genset, the temperature is about 550’┐Į?/SPAN>. For getting saturation steam with 0.4’┐Į?/SPAN>0.5MPa pressure , some 80’┐Į?/SPAN> cooling water of power generator will be entered into surplus heat boiler and make a use of sensible of fuel gas and exhaust to heat the water so as to produce steam.

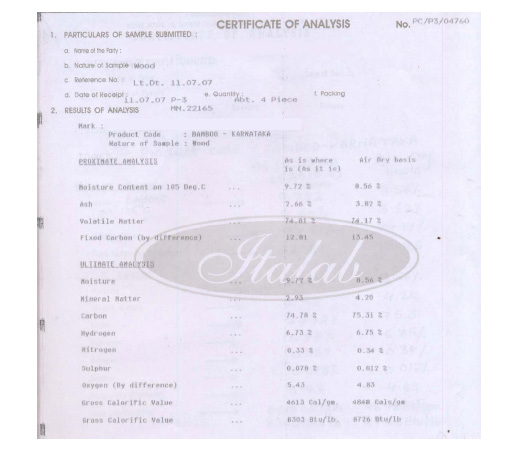

(5)Analysis report of bamboo

3. Raw materials collection,storage and preparation.

3. Raw materials collection,storage and preparation.

Biomass gasification furnace can adopt various crops biomass with moisture content 10%-20%. As primary consider, power plant is advised to stock enough materials for 3 month consum, , ption. Then, materials can be collected in the course of consumption. Power plant can sign one agreement with local supplier who is in charge of collecting materials. We suggest stock materials for at least 7 days consumption at any time

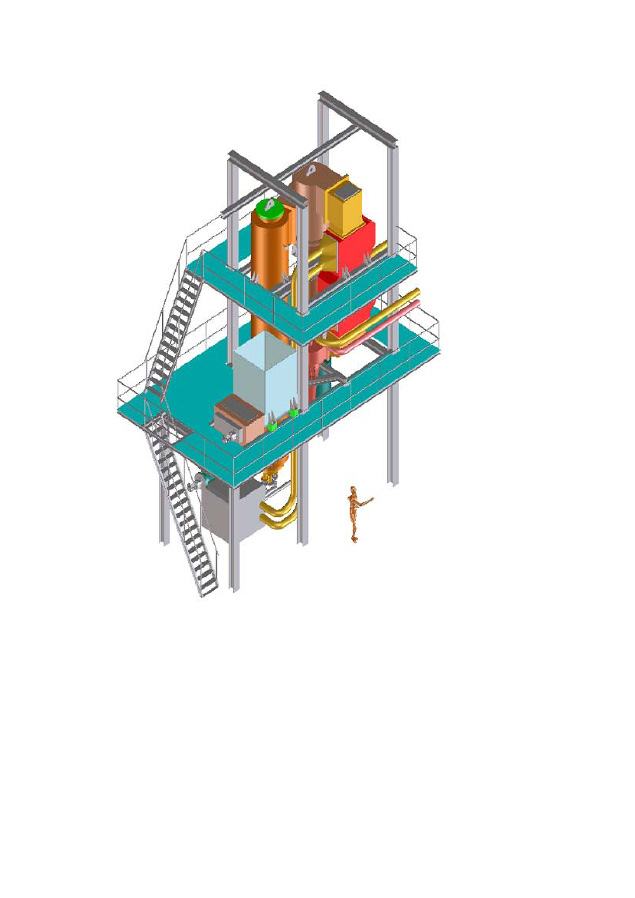

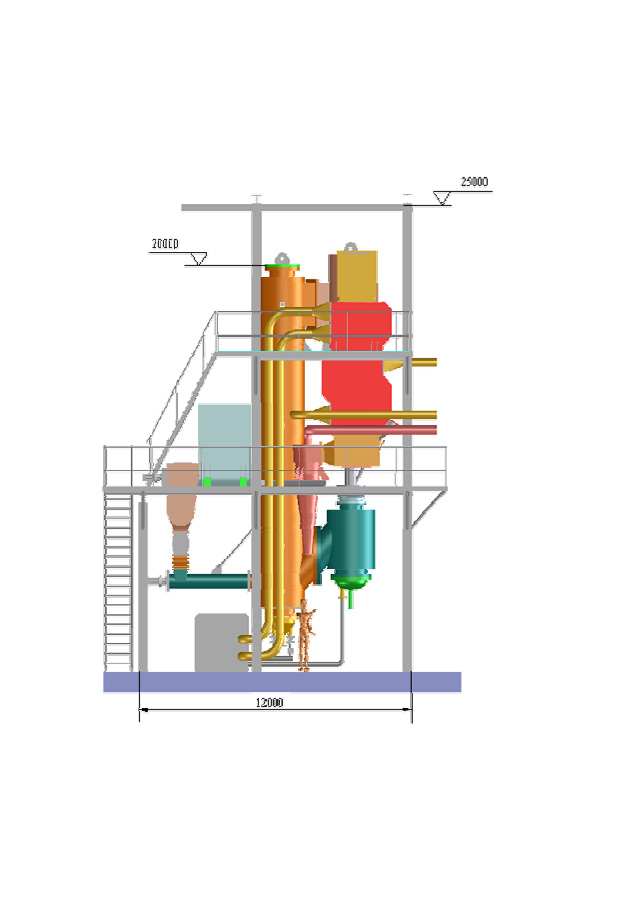

3.4 structure of gasification system

the gasification system include : (1)feeder (2)gasifier (3)cyclone separator (4)air preheater (5)air blower (6)induced draft fan (7)ash device 8) automatic controlling device

Bamboo access to gasifier through feed located on the bottom of gasifier. Preheat air access to gasifier through air board located on the bottom of gasifier. Fuel gas after purification will access to generator. Ash device are fixed on the bottom of gasifier to collect ash, which can be fertilizer after cooling.

3.5 Specifications of gen-set

Model:500GF1-RG & Picture of 500GF1-RG gas generator set

1.2ŃĆĆ/SPAN>Technical parameter 500GF1-RG

A.Technical specification of gas generator set

|

Mode |

500GF1-RG |

|

Engine model |

|

|

Generator model |

1FC6 |

|

Control panel model |

LCP1 |

|

Rated power(kW) |

500 |

|

Rated current(A) |

902 |

|

Rated voltage(V) |

400 |

|

Rated power factor, COS╬” |

0.8(lagging) |

|

Frequency(Hz) |

50 |

|

Starting method |

24V DC motor starting |

|

Voltage regulation |

Automatic voltage regulation |

|

Governing Method |

Electronic Governing |

|

Exciting method |

Brushless |

|

Phase and wiring |

Three-phase, four-Wire system |

|

Connecting Method between engine and generator |

Flexible coupling |

|

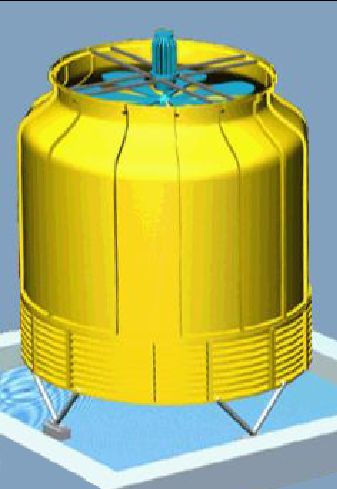

Cooling method of water cycle |

Cooling Tower(Open Type) |

|

Dimensions (l├Św├Śh),mm |

5344├Ś2170├Ś2955 |

|

Weight kg |

12350 |

B.Technical specification of gas engine

|

Engine model |

G12V190ZLDK-2 |

|

Type |

4ŌĆōstroke, Spark plug ignition, water-cooled ,with turbocharger and inner-cooler |

|

Cylinder arrangement |

V-type, 60oangle |

|

Cylinder bore mm |

190 |

|

Stroke Piston mm |

210 |

|

Total displacement L |

71.45 |

|

Rated power kW |

500 |

|

Rated speed r/min |

1000 |

|

Idle speed r/min |

550 |

|

Specific Oil Consumption g/kWh |

less than or equal 1.5 |

|

Exhaust temp. oC |

less than or equal 600 |

|

Water outlet temp. oC |

less than or equal 85 |

|

Oil temp. in oil pan oC |

less than or equal 90 |

|

Oil pressure in main oil gallery kPa |

400~800 |

|

Oil pressure in turbocharger kPa |

200~400 |

|

Stable speed droop (%) |

less than or equal 5 |

|

Cooling method |

Forced water cooling, heat exchanger with cooling tower |

|

Lubricating method |

Pressure and splash lubrication |

|

Cylinder number |

Output end |

1- 2- 3- 4- 5- 6

7- 8- 9-10-11-12 |

|

Ignition mode |

SI |

|

Ignition sequence |

1-8-5-10-3-7-6-11-2-9-4-12 |

|

Starting method |

24V DC motor starting |

|

Rotation direction |

Counter-clockwise (facing output end) |

|

Power output method |

Flywheel output |

|

Dimensions L├ŚH├ŚW mm├Śmm├Śmm |

2692├Ś2860├Ś1970 |

|

Weight kg |

5300 |

C.Technical specification of alternator

|

Generator model |

|

|

Rated power(KVA) |

625 |

|

Rated voltage(V) |

400 |

|

Rated current(A) |

902 |

|

Rated frequency(Hz) |

50 |

|

Rated power factor (lagging) |

0.8 |

|

Rated speed(r/min) |

1000 |

|

Protection class |

IP23 |

|

Insulation class |

Class F |

|

Cooling method |

Air cooling |

3.6 construction period

Whole set gasification power generation system adopt modularize designing. Each parts of whole system will be finished by our processing factory. Weight of one gasification furnace is approximately 100ton. Weight of Generator is approximately 20ton. Field basic construction is simple. The whole construction period is about 6months

China the most famous gas engine generator sets

For China gas engine generator sets or power plants, please click.