|

Batliboi Environmental Engineering Ltd, in association with BELTRAN TECHNOLOGIES ďż˝?USA , as

part of our endeavor to promote technologies to reduce the environmental pollution and preserve the

environment, will be promoting power generation from Waste to Energy by gasification technology.

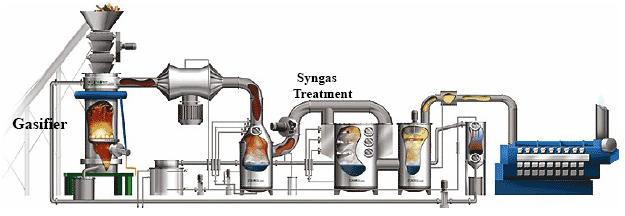

The Beltran Gasification Technology for biomass waste disposal and energy generation with

production of syngas for electricity and heat fulfills the requirements of integrated prevention and

reduction of environmental pollution. All of engine exhaust air and waste water is completely purified

by the integrated exhaust air- and waste water modules and thus can be released back to the

environment. Produced waste water reaches processing water quality.

In comparison to existing incineration plants no residues with detachable pollutant components remain

- even during the treatment of hazardous waste. This is an entirely novel aspect. Thus common

problems such as land filling of toxic residues and resultant unpleasant odour for residents do not

occur. Moreover, the process works with slight low negative pressure, thus preventing gas leakage and

unpleasant odour even during the actual process. The process releases back to the environment a far

lower amount of harmful substances than permitted. These results have never been achieved before

by any other existing technology.

|

The processing technology of Beltran for thermal biomass waste disposal and syngas generation,

including electricity and thermal energy is applicable to a wide range of biomass waste material,

including:

- Wood and woody materials

- Agricultural wastes such as coconut shells, palm shells etc.

- Combustibles recovered from Municipal and industrial wastes (RDF)

- Dry sewage sludge of waste water treatment plants

- Rubber and plastics waste including Tyre waste

- Chemical and oily waste

- Other combustible none-hazardous solid materials (SRF)

Plant sizes / Modular method of construction

The modular construction enables individualized adaptation of tasks. Beltran Gasification Plants as

well as the gas clean up modules and WESP - Plants are basically built in a modular way. This enables

a successive expansion via convenient single components when the demand is growing and cost

effectiveness when the plant is not operating at full capacity. Therefore, the plant conception of Beltran

can be expanded at any time and, likewise, unused capacities which can be turned off.

The standard gasification module is designed for continuous operation and has availability of more than

8000 hrs per year (>91%). It has a single module capacity of 30 ton/day RDF (minimum GCV = 17

MJ/kg) which will produce 3125 Nm3/hr clean syngas. According to the requirements the modules can

be expanded by combining modules up to plant capacity of 150 ton/day.

Area of proposed one gasifier module: 20m (L) x 20m (W) x 12m (H)

Total site footprint required area for one gasifier module with power generator is 20m x 20m.

Operation Facilities:

The demand for operation facilities for running the operation of Beltran Gasification Plant is, in

comparison to existing incineration technologies, very low. The Beltran Technology requires only a

small amount of external energy; nearly all processes are fed by energy produced during the process.

Only small amounts of consumable material (e.g. propane/butane gas or fuel oil for conventional

ignition during start-up and flare pilot torch, make up water for water scrubber and plasma-WESP) is

necessary. However, these consumables are negligible amount consumables. The internal electrical

energy demand of the gasification plant is around 5% of the total energy produced by the gasification

plant. Therefore, only maximum 75kWe is needed to operate 1.5MWe output each gasification plant.

Typical Expected Syngas composition from RDF gasification

| Syngas |

% Volume (Dry) |

| H2 |

17.5 |

| CO |

20.8 |

| CH4 |

3.3 |

| N2 |

45.8 |

| CO2 |

11.4 |

| C2H4 |

0.7 |

| C3H6 |

0.4 |

| GCV (MJ/Nm3) |

6.2 | If we are given the available waste / Biomass composition and the qty T/Hr, we can calculate and

design a suitable Gasification system for you.

|