| 1) BELT,DRIVE,SPC,6000mm,22x18mm 216 SET

Belts, Drive

Type WEDGE BELT

Design spec BS 3790 LATEST EDITION

Section designation SPC

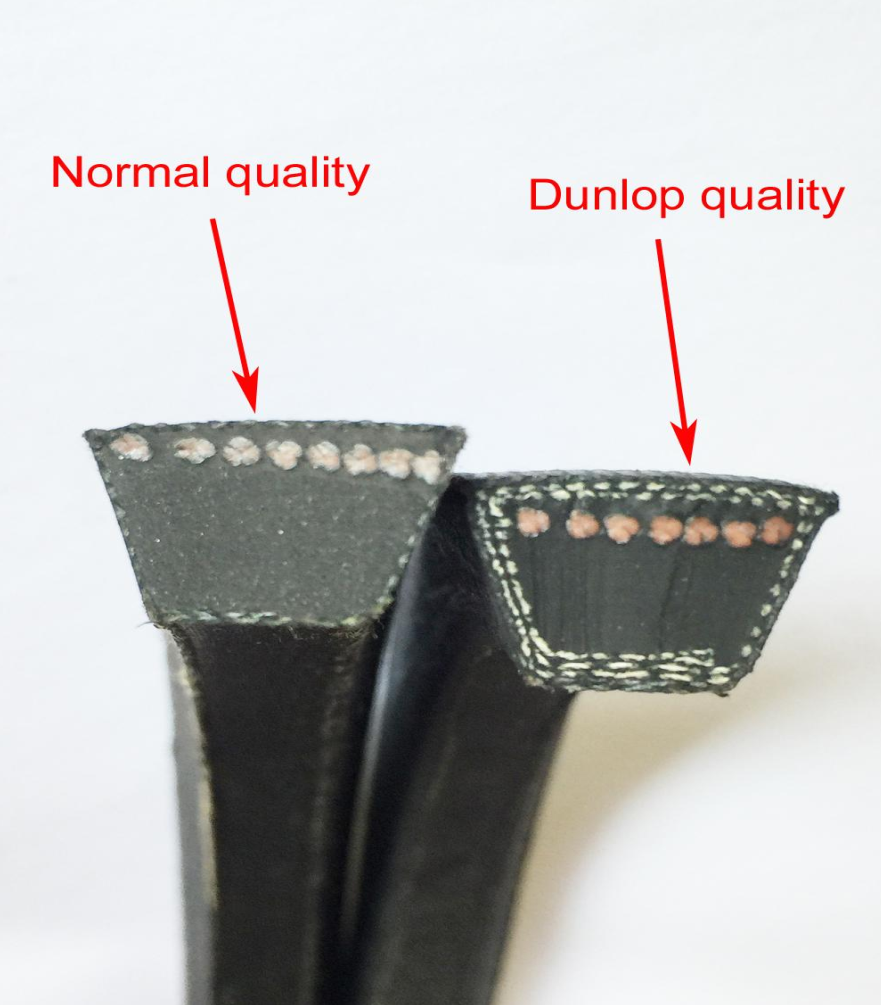

Mat NEOPRENE FILLER

NEOPRENE IMPREGNATED COVER

POLYESTER CORD

Requirements OIL-FIRE RESISTANT,ANTI-STATIC

Width 22 mm

Height 18 mm

Length, pitch 6000 mm

| Description | Type

| Top width | Height | pitch length | Qty

|

|

| mm | mm

| mm | pcs | | Rubber v belt | SPC6000(22x18) | 13 | 8 | 6000 | 220 |

1: Due to quality inspection and mold production, the final quantity will have a difference of ±5.

2: The production standard is produced according to the international standard "Pitch length".

Methods for maintaining and extending the life of the V-belt:

1. Keep it clean---clean regularly: remove oil, dust and impurities on the surface of the V-belt to prevent these substances from accelerating the aging of the rubber or affecting the friction performance. Prevent contact with grease, chemical solvents or acid-base substances, which will corrode the rubber and reduce the strength of the belt. 2. Prevent overload---reasonable tension: ensure that the tension of the V-belt is moderate, too tight will accelerate wear, too loose may cause slipping or falling off. 3. Avoid overload operation---control the load of the equipment within the rated range to prevent breakage or tensile deformation caused by overload. 4. Regular inspection---Observe the wear condition: Regularly check whether the V-belt has cracks, hardening, peeling or severe wear, and replace it in time if problems are found. Check the pulley groove: Make sure that the pulley groove is not damaged or foreign matter to prevent additional wear on the V-belt. 5. Avoid long-term disuse---start the equipment regularly: If the equipment is out of use for a long time, it should be started and operated regularly to prevent the V-belt from being deformed due to long-term static pressure. Storage precautions: Uninstalled V-belts should be stored in a dry, cool place, away from direct sunlight or heavy objects.

Package:

|