|

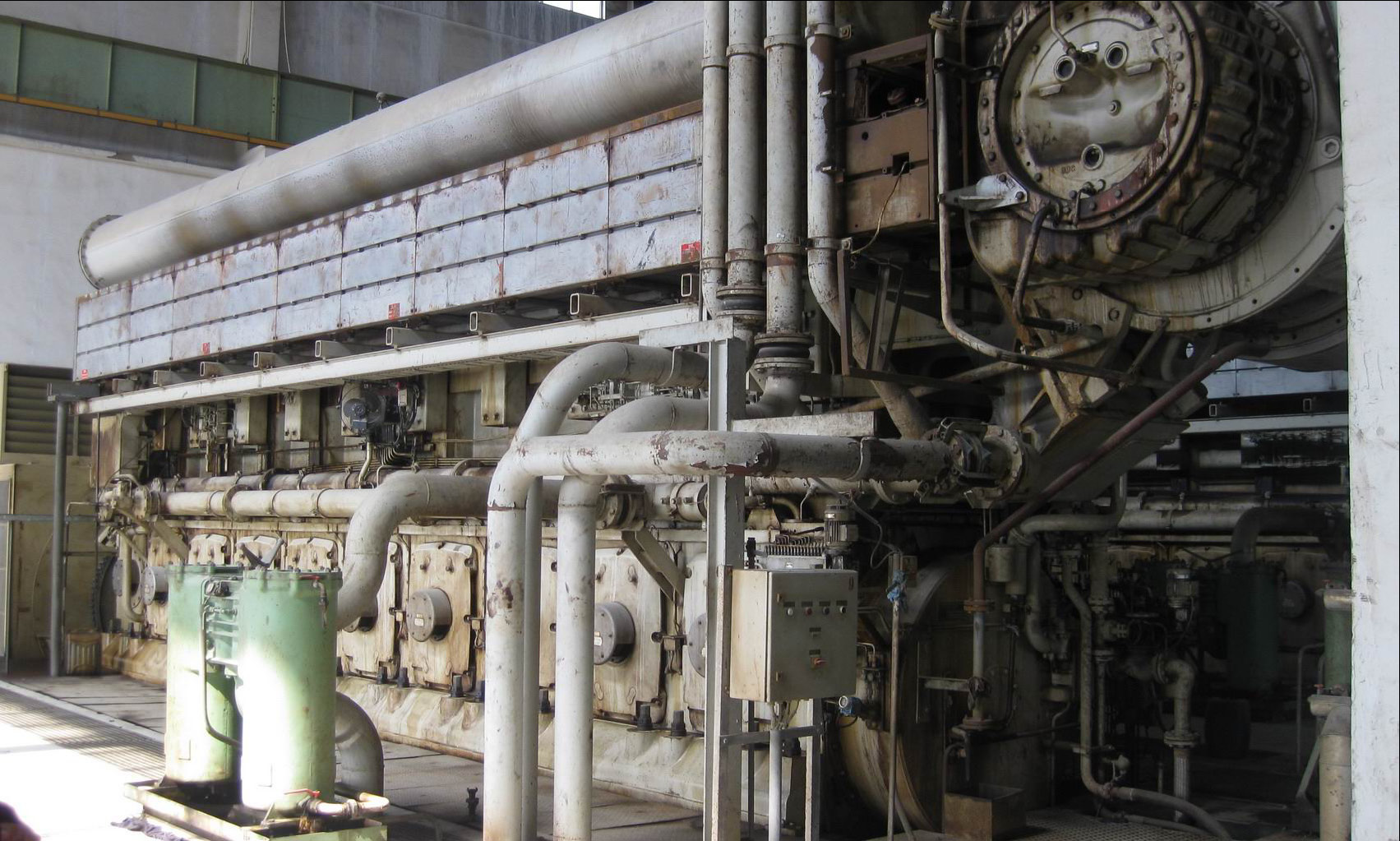

WHOLE POWER PLANT WITH STORK WARTSILA DIESEL

9TM 620 x 9 UNITS FOR SALE.

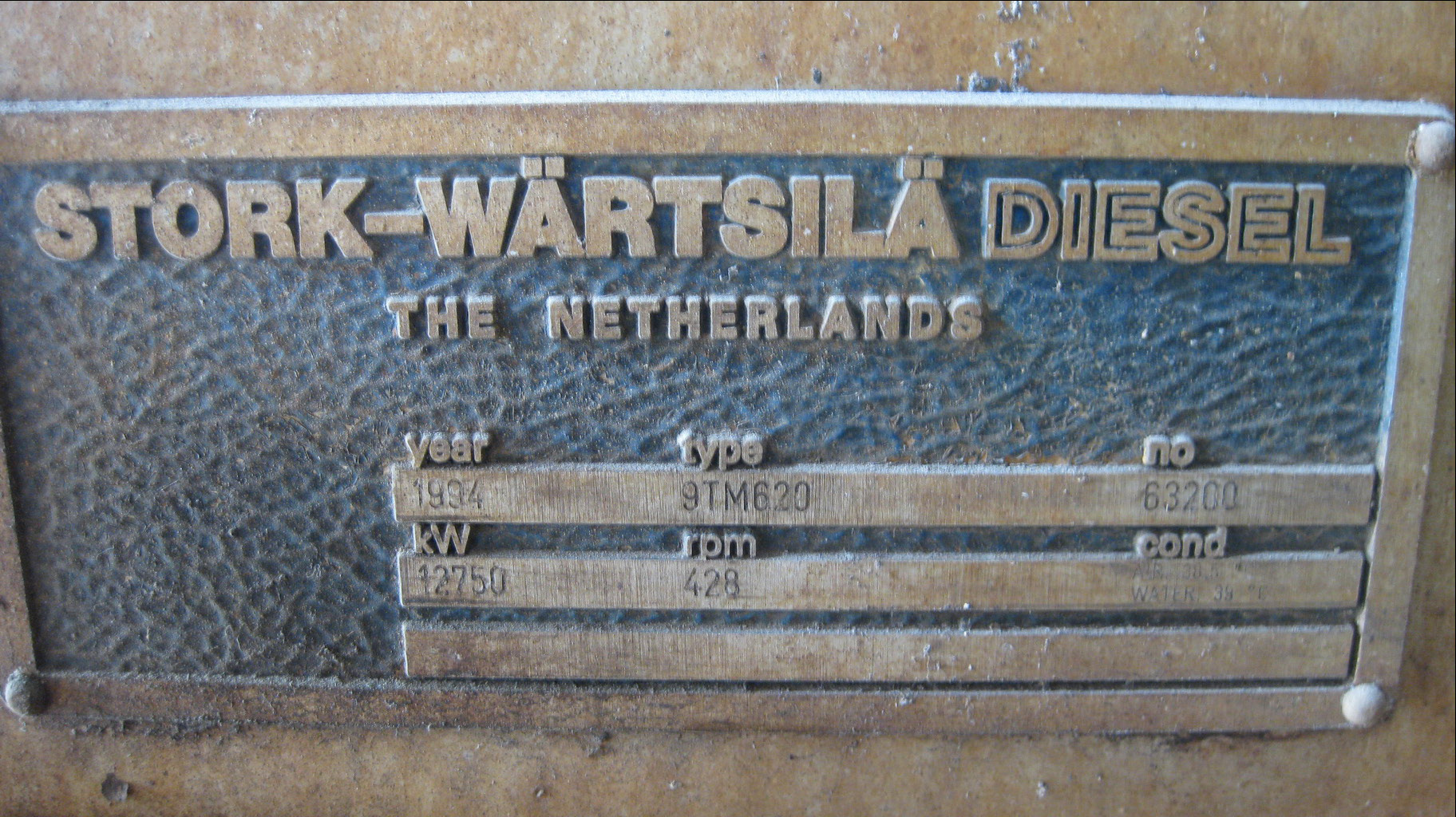

YEAR BUILT 1994

12750 KW

11000 VOLTS

50 HZ

428 RPM

SERIAL NO. 63200 TO 63208

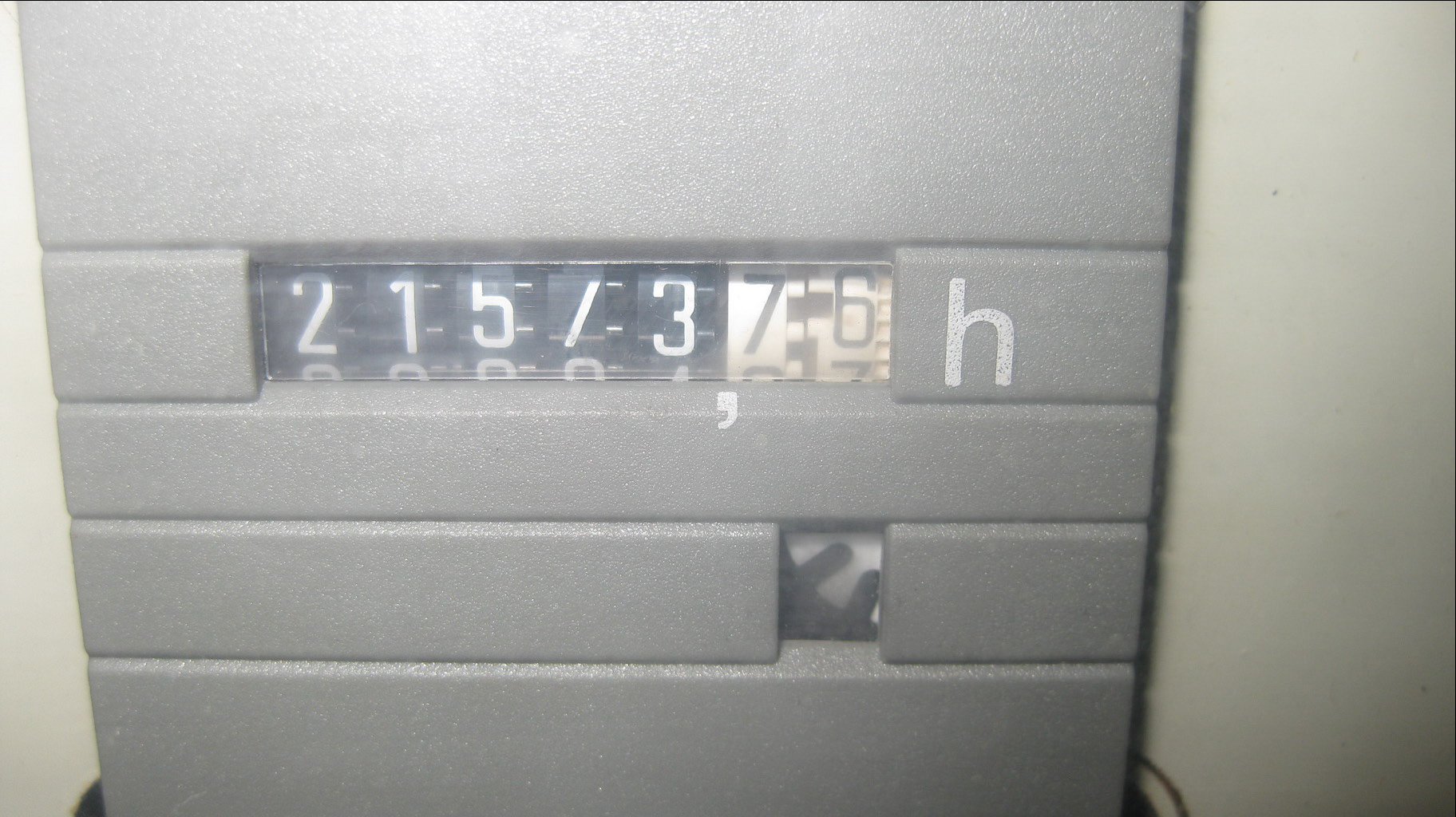

RUNNING HOURS :- 22000 SINCE NEW

NOTE :- ALL UNITS HAS BEEN OVERHAULED ON EVERY 10000

RUNNING HOURS ,

TOTAL OVERHAULED TWICE SINCE NEW

THE PLANT HAS BEEN STOP RUNNING ON YEAR 2008 .....

DUE TO HIGH COST ON DIESEL FUEL

ALL ACCESSORY ATTACHED INCLUDED

USD 1.5 Million /unit as where they are on site, without

warranty.

Yangchunlin

Leda Greenpower/CEO

http://www.china-power-contractor.cn

Email:[email protected], [email protected], [email protected]

Tel/Fax: 0086 10-84568952

Mobile: 0086 13801218512

D-803, Shengshijiayuan, Road 98, Jianguo, Beijing 100022, China

Commercial Proposal for the sale of Power Plant

nits of HFO/Diesel Power Plant

Wartsila 9TM620

12.75 MW each (ISO Condition), making 114 MW

11 kV, 50 Hz, 428 rpm

(not practible to convert these to also burn natural gas)

Introduction

We are offering a generating solution consisting of Nine (9) units of Wartsila 9TM620 Engines,

50 Hz, 428 rpm, 12.75 MW each, for a total gross Plant Output at site of 114 MW ISO

conditions.

This proposal is subject to the General Commercial Conditions stated in this document,

Preliminary Project Schedule and the Scope of Supply.

We’re seeking to establish lifelong relationships with its Customers, thus our Seller also offer

service and support solutions.

In addition, as per Customer request, Seller is able to offer a long-term O&M agreement,

covering parts and services…�

At factory conditions, the Power Plant is able to operate with the following parameters of fuel

efficiency: 174 g/kWh ISO Conditions

Scope of Supply

The Equipment and services provided in this Proposal are described as follows:

Engines

Manufacturer : Wartsila Diesel

Model : 9TM620

Frequency: 50 Hz

Rated Output : 12,750 kW each

Rated speed : 428rpm

Fuel Consumption : 174 g/kWh +/- 5%

Lube Oil Consumption : 1.3 + 0.3 g/kWh

Year of manufacture : 1993-1995

Service Hours : average 25,000 hours

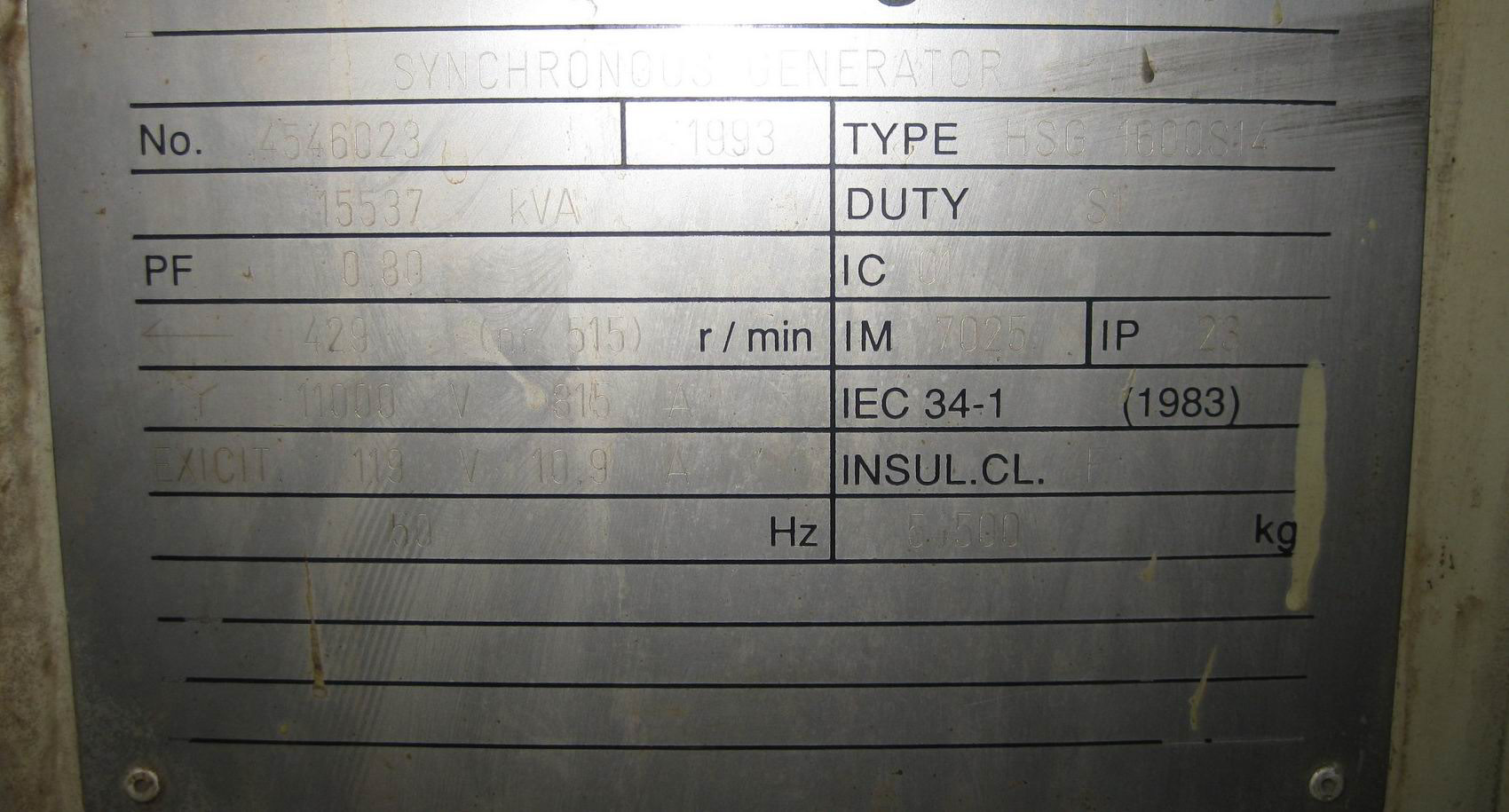

Generators

Type: HSG 1600 S14

Rated capacity:15,537 kVA

Power Factor : 0.8

Frequency : 50 Hz

Rated current : 815 A

Rated voltage : 11 kV

Greatest weight/piece : 55 tons

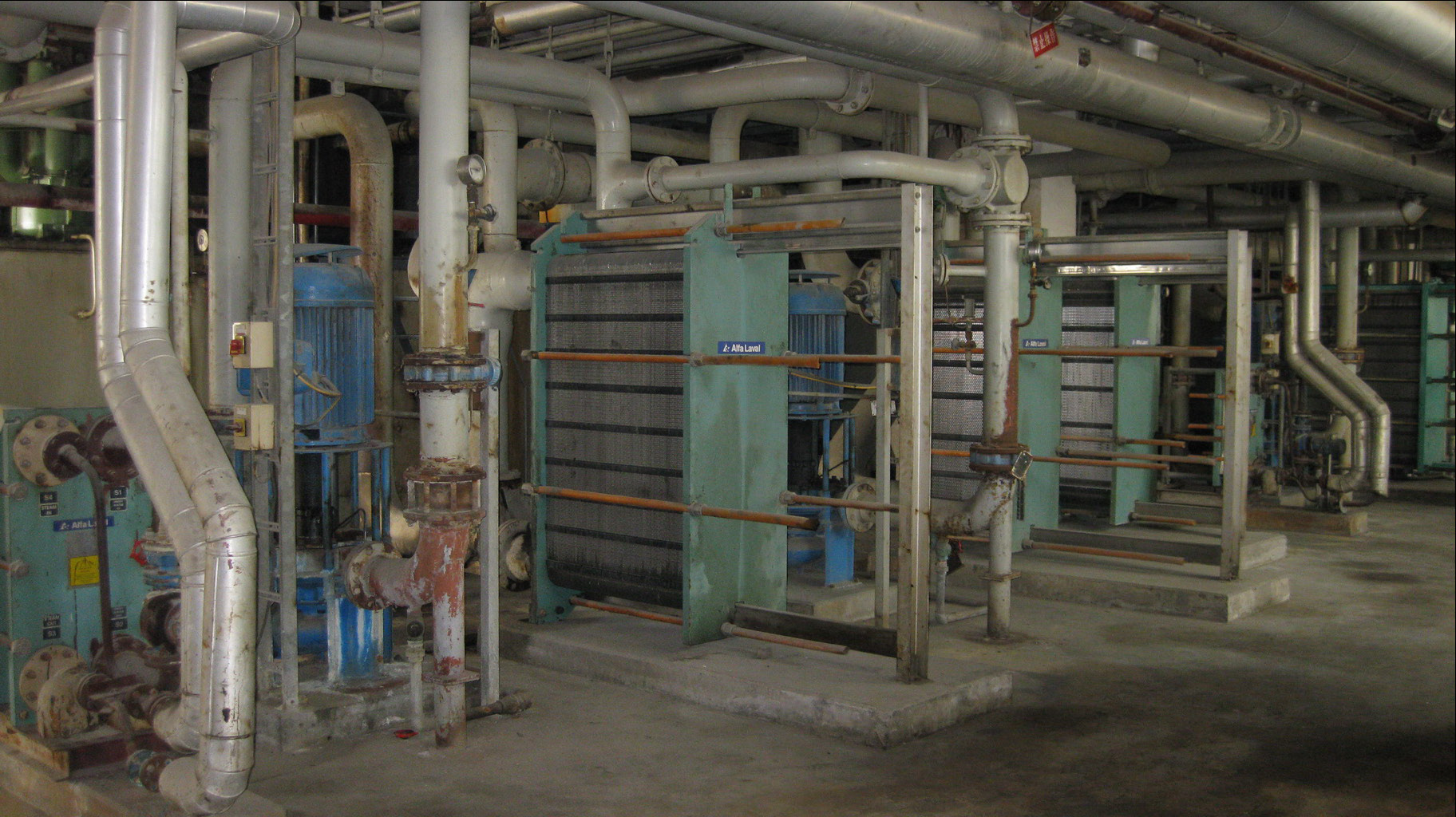

Plant & Engine Accessories

The Plant and Engines shall be provided with the following main and auxiliary systems:

Mechanical System

Staring System - Compressed Air System

Starting Air Compressor

Control Air Compressor

Air Receiver Module, Service/Starting

Air Bottle

Air Receiver Automatic Drains

Charge Air System

Air filter

Silencer

Ducting

Cooling Water System

Cooling tower - New

Cooling water feeding pumps

Raw Water circulating pump

Cylinder Liner Cooling Water Expansion Tanks

Cylinder Liner Cooling Water Expansion pumps

Cylinder Liner Cooling Water condenser

Cylinder Liner Cooling Water Buffer Tank

Compensation Tank

Fuel System

DFO System

Day tank

DFO daily tanks feeder Pump and Filter

DFO Transfer Pump

DFO Feeding Pump

Fuel meter

DFO Booster

DFO Pre Pressure Pump

DFO Automatic Duplex Filter

Fuel Oil Mixing Tank

HFO System

Fuel meter

HFO daily tanks feeding pump

HFO feeding Pump

Fuel feeder/booster unit

HFO Pre-heater

HFO Buffer Tank

HFO Separator Unit

HFO Pressure Circuit and circulation Module

Lubrication Oil System

Circulation System pump

Lube Oil Feeding Pump

Lube Oil Control Valve

Cylinder Liner Lube Oil Tank

Lube Oil Primary Filter

Lube Oil Secondary Filter

Lube Oil Heater

Lubrication Oil Service Module/ oil separator units

Lubrication Oil heat exchanger / lube oil cooler

Lube oil automatic filter

Leakage Oil Recovery Tank

Heat Recovery System

Steam System

Steam Exhaust Boiler

Feed Water Tank

Circulating Pump Boiler

Mixing Tank

Exhaust Gas System

Silencer w/Supporting Brackets

Ducting

Insulation

Switchgear and Control System

Engine Auxiliaries MCC

Common Auxiliaries MCC

Main Switch Gear

Main Bus Bar

Generator Cubicle / Engine Control Panel

Measuring Cubicle

DC System

DC Board

Battery Charger Panel & Batteries

Price and Payment Terms, Commercial Conditions - on as-is-where-is condition

Price US$ . Million each unit for total plant of units

Payment Terms:

30% down payment

30% payment before start of dismantling

40% payment before delivery from Power Plant

All Equipment is quoted “where is as is�? subject to inspection and prior sale.

U$180,000 per unit for Dismantling, Packaging and Transportation to the nearest port

If the customer wants to run the units, they can run in idle (no load). Please be noted that there is

additional charge of U$3000 per unit for the Engine Empty Running test the fee needs to be

settled three (3) days in advance and non-refundable.

To ensure a successful deal, required temporary down payment of U$800,000 right after the site

visit and after meeting with the owner to confirm the paperwork of Title or Ownership....

Scope-of-supply must be verified by customer during inspection.

Seller is not responsible for errors or omissions during site visit.

Validity is not exactly specified but "subject to prior sale"

Notes:

Buyer should be responsible for all Equipment duties, taxes of all kind and licenses fees

imposed by the national and-local government.

It is expressly understood and agreed that Seller makes no warranty and assumes no

responsibility, expressed or implied, for the condition, performance, maintenance, manufacture,

or design of the goods.

Seller makes no other representation and disclaims any other warranty, whether statutory,

written, oral, express, or implied, including but not limited to any warranties of merchantability,

fitness for a particular purpose or arising out of any course of dealing or usage of trade.

Any information provided by seller which relates to the goods is or will be for informational

purposes only and is not and will not be guaranteed or warranted.

9 units of "Wartsila" Engine Power Plant Engine Information

Engine

Manufacturer : Wartsila

Model : 9TM620

Capacity : 12750 kW,@ 50 Hz

Alternator

Manufacturer : ABB

Model : HSG1600S14

Capacity : 15537 kVA @ 50 Hz

|

item |

Engine No. |

Year Build |

Operating Hrs. |

Last Overhaul Hrs. & Date |

|

1 |

62400 |

1994 |

25823 |

25,000Hrs.26/05/2008 |

|

2 |

62500 |

1994 |

25204 |

24,000Hrs.01/04/2008 |

|

3 |

62600 |

1994 |

26955 |

25,000Hrs.20/05/2008 |

|

4 |

62700 |

1994 |

26766 |

26,000Hrs.01/07/2008 |

|

5 |

62800 |

1994 |

25541 |

25,000Hrs.30/05/2008 |

|

6 |

62900 |

1994 |

25611 |

24,000Hrs.26/03/2008 |

|

7 |

63000 |

1994 |

27907 |

26,000Hrs.04/06/2008 |

|

8 |

63100 |

1994 |

26995 |

26,000Hrs.08/07/2008 |

|

9 |

63200 |

1994 |

21573 |

20,000Hrs.20/04/2008 |

Q&A

Many thanks for your clarification. but kindly advise on the following:-

1- Approximate Dismantling/Packaging Transport to Nearest Sea Port Costs?

A: the dismantling, packing and transportation to port cost is about 500,000USD per unit. The total time of dismantling is about 70-90 days.

2- Will you the Seller Bear the Cost of S.G.S/Wartsila costs for pre-shipment verification?

A: this can be included in the contract for the buyer who paid us advance payment.

3- Number of Containers that will be required to fully Ship the entire unit?

A: all need 60-65 containers to contain the parts and engines. Already 5 containers are available for containing 5 units of auxiliaries.

Also advise on following specifications:-

1- Power Plant Efficiencies that is how many liters of diesel required to generate 1 MW of Electricity.

A: the fuel consumption is around 186gram/KWH, with 5% fluctuation, lube oil consumption is around 1gram/KWH. Data is to our operation.

2-In the same line using your historic data- how much fuel required per day to run the plant at various capacities?

2- Also advise how many square metres of Closed Shed and open space required to commission the plant in Destination country? Total Area to be allocated and necessary to smoothly operate the Power Plant.

A: we have full sets of drawing of the plant, but you can refer to the attached similar drawing for 100mw hfo plant.

3- Also advise on Noise Levels and whether silencers have been installed to minimize the noise level.

A; yes, there is silencers installed to reduce the noise level to meet standards.

5-Finally Advise how many Full-time Workers required to efficiently operate this plant.

A: usually the operation and maintenance need 23 persons in two shifts, each shift is 9 person, balance are managers and supervisors.

The above will guide us as part of the Planning Package for Financing this Asset.

|