Gas Turbine Speed Reducer Gearbox

|

Gas Turbine Inlet Air Filter

6. Heat Recovery Steam Generator

Heat Recovery Steam Generator is HENRY VOGT make; installed downstream of the exhaust duct of the Gas Turbine, it receives the hot flue gas from the Gas Turbine itself and produces steam at two different pressure levels.

| License |

# |

Henry Vogt Machine Co. (USA) |

| Designer |

# |

MIR (Italy) |

| Manufacturer |

# |

COMEF (Italy) |

| Manufacture Year |

# |

1997 |

| Type |

# |

Water tubes, horizontal gas flow, natural circulation |

| HP section |

# |

Economizer, Evaporator, Superheater |

| HP steam pressure |

Barg |

83 |

| HP steam temperature |

°C |

523 |

| HP steam flow |

t/h |

106,7 |

| HP flow with Post-firing |

t/h |

135 |

| LP section |

# |

Economizer, Deareator, Evaporator, SH |

| LP steam pressure |

Barg |

3 |

| LP steam temperature |

°C |

191 |

| LP steam flow |

t/h |

18,6 |

| Post-firing Manufacturer |

# |

De Jong-Coen |

| Post-firing Fuel |

# |

Gas |

| Steel Stack |

m |

50 (h) |

| BMS manufacturer |

# |

Hartman & Braun |

|

Heat Recovery Steam Generator

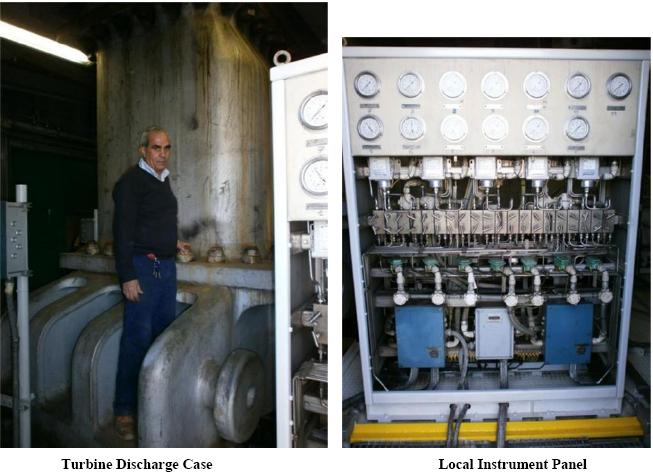

7. Steam Turbine

The Steam Turbine is manufactured by General Electric / Nuovo Pignone.

Turbine is provided with turning gear and SSS Gears make clutch allowing connection/disconnection between the Turbine itself and the Generator.

Steam Turbine Major Inspection was perfo0rmed in 2009.

| Manufacturer |

# |

General Electric / Nuovo Pignone |

| Model |

# |

HNK 50/90-3 |

| 1st synchronizing |

# |

Oct-97 |

| Power output |

Mwe |

23,05 |

| Inlet steam pressure HP |

Bar |

82 |

| Inlet steam temperature HP |

°C |

515 |

| Inlet steam pressure LP |

Bar |

2,2 |

| Inlet steam temperature LP |

°C |

191 |

| Condensing pressure |

Bar |

0,06 |

| Turbine Speed |

rpm |

3 |

| Steam Condenser |

# |

Surface type / Water cooled |

| Condenser Manufacturer |

# |

Wellman Graham |

| Condensing Tubes Material |

# |

A249 TP 304L |

|

/P>

|

8. Synchronous Generator

Generator last inspection (including visual and borescope inspection, polarization index, insulating resistance test and stator winding resistance) was performed in 2009.

| Manufacturer |

# |

General Electric |

| Model |

# |

7AG |

| Power output |

MVA |

110 |

| Power Factor |

Cos-fi |

0.85 |

| Cooling System |

# |

Air to W, ater Cooled |

| Speed |

Rpm |

3.000 (2-pole) |

| Frequency |

Hz |

50 |

| Rated Voltage |

V |

11.5 |

| Rated Current |

A |

5.522 |

| Insulation Class |

# |

F |

| Excitation type |

# |

Static |

| Excitation Model |

# |

EX2.000 -General El |

| Generator Starter |

# |

Static type |

| Static Starter Model |

# |

Directo-Matic 2.000 General Electric |

Air insulated bus ducts downstream Generator

|

9. Fuel Gas Compression Station

Gas Compressors have been overhauled in 2010.

| Compressors Manufacturer |

# |

Nuovo Pignone |

| Number of Units |

# |

2 (1 duty, 1 stand-by) |

| Model |

# |

2HM/1 |

| Type |

# |

Reciprocating |

| Rated Flow Rate |

Nmc/h |

22.75 |

| Design Press. (inlet/outlet) |

Bar g |

16 / 29 |

| Design Temp. (inlet/outlet) |

°C |

20 / 65 |

| Speed |

Rpm |

740 |

| Mechanical Power |

kW |

500 |

| Regulation Steps |

% |

0-50-75-100 |

| Electric Motor Manufact. |

# |

ABB |

| Motor Voltage |

V |

6.300, 3-phase |

| Motor Cooling System |

# |

Water |

| Motor Lube System |

# |

Upgraded to oil free |

|

|

|

Gas Compression Station

10. Step-Up Transformer

Generator is connected, via an air-insulated bus duct, to a three windings Step-Up transformer, ABB make. Third winding (MV2) is available for a future expansion, to be connected to the generator of a second steam turbine.

| Transformer Make |

# |

ABB |

| Manufacture Year |

# |

1996 |

| Number of Units |

# |

1 |

| Manufacture Year |

# |

1997 |

| Installation |

# |

Outdoor |

| Windings |

# |

3-phase (1 primary HV; 2 secondary MV) |

| Frequency |

Hz |

50 |

| Voltage level (HV) |

kV |

139.8 +/-8x1.25% |

| Voltage levels (MV1-MV2) |

kV |

11.5 |

| Rated Power (HV/MV1/MV2) |

MVA |

141.5 / 112 / 29.5 |

| Rated Current (HV/MV1/MV2) |

A |

584,4 / 5.623 / 1.481 |

| Connection groups |

# |

YN-d11-d11 |

| Cooling Type |

# |

Onaf |

|

Bus duct connection between Generator Circuit Breaker and Main Transformer