| Internationally renowned membrane manufacturer, an expert in wastewater resource utilization world leader in MBR, an envoy for drinking water safety

The supplier is a high-tech enterprise founded by overseas returned scholars in 2001 in Zhongguancun National Independent Innovation Demonstration Zone. The company has a whole-industry-chain membrane technology (including microfiltration, ultrafiltration, nanofiltration, reverse osmosis) with completely independent intellectual property rights. It is also the only enterprise in China that integrates membrane material research and development, membrane equipment manufacturing and membrane process application.

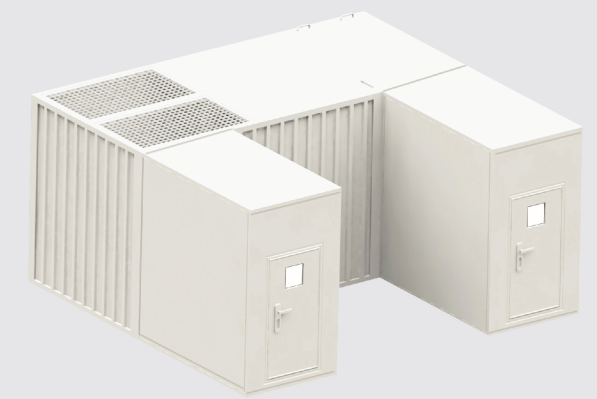

1. The Compact Wastewater Treatment System (CWT), abbreviated as CWT, is an integrated and highly efficient point source sewage treatment equipment independently innovated and developed by Supplier.

2. It is a high-tech product that organically combines biotechnology and membrane technology, with characteristics such as modularization, intelligence, convenient transportation, quick installation, high efficie ncy and energy conservation, and does not require special personnel on duty. It is suitable for the treatment of various small and medium - sized decentralized domestic sewage and similar industrial organic wastewater, such as rural domestic sewage, public toilets, independent villas, tourist attractions, river sewage interception and emergency wastewater treatment, etc. It is widely used in regions such as Beijing, Zhejiang, Jiangsu, Yunnan and Inner Mongolia, and nearly ten thousand sets have been applied currently, making it an ideal sewage treatment equipment for scattered tourist areas in villages and towns.

| | Good effluent quality, good effluent quality, | Equipment integration, small footprint, convenient transportation; | Modular structure, can be arbitrary Modular structure, can be arbitrary | Low operating cost, wide range of adaptation; | APP intelligent remote control, no duty required. |

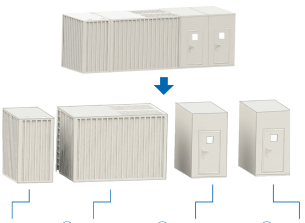

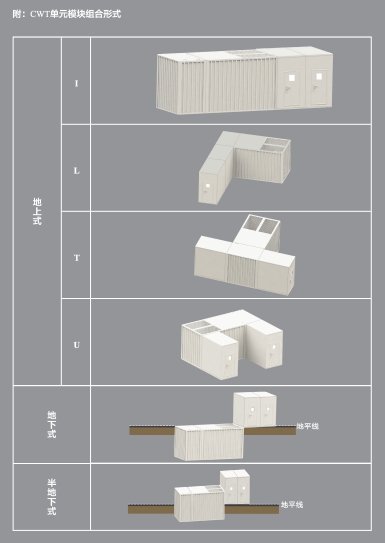

CWT adopts a modular design and is composed of four basic module units. According to the sewage purification requirements and the actual situation on site, its basic module units can be freely combined. According to the discharge or reuse requirements, there are two combination forms, namely CWT - A and CWT - B. When the effluent water quality standard is relatively high, the CWT - A type is recommended, which is mainly composed of all modules (�?is optional), and the effluent water quality meets the Class IV (TN < 15mg/L) limit of the Environmental Quality Standards for Surface Water (GB3838 - 2002). When the effluent water quality mainly requires the removal of organic matter, nitrogen and phosphorus, the CWT - B type is recommended, which is mainly composed of unit 2 and unit 3, and the effluent water quality meets the "Urban Sewage Reuse - Water Quality Standards for Urban Miscellaneous Water Use" (GB18920 - 2002) and the "Urban Sewage Reuse - Water Quality Standards for Landscape Environmental Water Use" (GB18921 - 2002). Anoxic unit, aerobic + membrane tank unit, control + equipment unit, office area (optional) Biochemical and membrane unit, composed of control system and equipment system, optional, mainly for Steel structure oil body, optional with remote transmission control and APP and other functions, above - ground device configuration

Figure 1 Four basic modular units of CWT

| Anoxic unit | aerobic + membrane tank unit | control + equipment unit | office area (optional) | | Biochemical and membrane unit mainly for Steel structure oil body | composed of control system and equipment system optional with remote transmission control and APP and other functions | above - ground device configuration |

CWT integrated system | villages and towns, parks, scenic spots, emergencies) decentralized pollution, decentralized pollution sources | pretreatment tank | anoxic tank | aerobic tank | membrane tank | high - quality recycled water, reflux |

CWT - A Product Specification TableCWT - A Product Specification Table| Model | CWT - A - 10 | CWT - A - 20 | CWT - A - 30 | CWT - A - 50 | CWT - A - 100 | CWT - A - 200 | CWT - A - 300 | CWT - A - 500 |

|---|

| Daily treatment capacity (m³/d) | 10 | 20 | 30 | 50 | 100 | 200 | 300 | 500 | | Length × Width × Height (m) | 2.2 × 1.2 × 2.2 | 3.0 × 1.5 × 2.2 | 3.5 × 2.0 × 2.2 | 4.2 × 2.0 × 3.0 | 6.2 × 2.5 × 3.0 | 11.3 × 2.5 × 3.0 | 8.4 × 2.5 × 3.0 × 2 units | 14 × 2.5 × 3.0 × 2 units | | Operating power (kW) | 1.31 | 1.57 | 2.26 | 3.62 | 4.32 | 8.42 | 9.92 | 12.37 |

CWT - B Product Specification TableCWT - B Product Specification Table| Model | CWT - B - 100 | CWT - B - 200 | CWT - B - 300 | CWT - B - 500 |

|---|

| Daily treatment capacity (m³/d) | 100 | 200 | 300 | 500 | | Length × Width × Height (m) | 3.3 × 2.5 × 3.0 | 5.5 × 2.5 × 3.0 | 7.6 × 2.5 × 3.0 | 12.0 × 2.5 × 3.0 | | Operating power (kW) | 3.55 | 7.3 | 8.8 | 10.5 |

New rural water environment treatment, farmhouse tourism spots, ecological parks; residential quarters, office buildings, hotels and restaurants, park scenic spots; important sewage treatment, such as folk tourism villages, natural scenic spots, etc.; temporary sewage treatment, such as construction sites, etc., with a relatively short service cycle. Note: Tables 1 and 2 are typical standardized models, and the actual application can be adjusted according to the actual water quality.

2. For capacities exceeding those in the table, multiple modules can be combined or multiple sets of equipment can be operated in parallel. 3. Only the equipment foundation, corresponding power supply and connecting pipelines need to be installed on site. 4. Sewage purification equipment CWTT of traditional process can be customized according to needs.

CWT Main Influent and Effluent Water Quality IndicatorsCWT Main Influent and Effluent Water Quality Indicators| Serial Number | Indicator | Influent Water Quality | CWT - A Effluent Water Quality | CWT - B Effluent Water Quality |

|---|

| 1 | Chemical Oxygen Demand COD₀ (mg/L) | <350 | <30 | <50 | | 2 | Biochemical Oxygen Demand BOD₅ (mg/L) | <150 | <6 |

| | 3 | Total Nitrogen TN (mg/L) | <45 | <15 |

| | 4 | Ammonia Nitrogen NH₃ - N (mg/L) | <35 | <1.5 | <5 | | 5 | Total Phosphorus TP (mg/L) | <4 | <0.3 | <0.5 | | 6 | Suspended Solids SS (mg/L) | <200 | <5 | <10 |

CWT Main Technical and Economic IndicatorsCWT Main Technical and Economic Indicators| Serial Number | Indicator | CWT - A | CWT - B |

|---|

| 1 | Unit water volume occupied area (m²/m³) | 0.15 - 0.3 | 0.06 - 0.15 | | 2 | Unit water volume electricity consumption (kW•h/m³) | 0.6 - 1.0 | 0.4 - 0.8 | | 3 | Unit water volume direct operation cost (yuan/m³) | 0.7 - 1.0 | 0.6 - 0.9 |

Scope of Application

Scope of Application of CWT - A:

Water source protection areas and environmentally - sensitive areas; water environment treatment in new rural areas, farm - stay tourism spots, and ecological parks; Treatment and reuse of domestic sewage from other decentralized point sources; residential quarters, office buildings, hotels, restaurants, and park scenic spots.

Scope of Application of CWT - B:

Transitional sewage treatment, or sewage treatment in urban - rural fringe areas without sewage networks and accident treatment of sewage outfalls; sewage treatment of important areas, such as folk - custom tourism villages and natural scenic spots; Emergency sewage treatment for sudden incidents, such as rapid remediation of overflow sewage and black - odorous water bodies; temporary sewage treatment, such as on construction sites, with relatively short service cycles.

Typical CasesTypical Cases| Project Name | Treatment Capacity | Model |

|---|

| River Sewage Interception Project in Shuangliu District, Chengdu City | 100t/d | CWT - A - 100 | | Municipal Sewage Treatment Project in Zhongxiang City, Wuhan | 7400t/d | CWT - A - 200, CWT - A - 300, CWT - A - 400, CWT - A - 500 | | Sewage Treatment Project in Chaoyang, Liaoning | 500t/d | CWT - A - 500 | | Emergency Sewage Treatment Project for Sewage Outfalls and Exit Section in Changping District, Beijing | 3400t/d | CWT - A - 300, CWT - A - 500 | | Upgrading and Reconstruction of Sewage Treatment Plant in Northern Haidian District, Beijing | 100t/d | CWT - A - 100 | | National Wetland Park Project of Shiyang River in Minqin, Gansu | 50t/d | CWT - A - 50 | | Yazi Lake Treatment Project of Jingxi School | 300t/d | CWT - A - 300 | | Sewage Treatment Project in Miyun Villages and Towns | 800t/d | CWT - B - 100, CWT - B - 200, CWT - B - 300 | | Sewage Treatment Project in Qianjiang Townships, Hubei | 30t/d | CWT - A - 30 | | "Beautiful Village" Project in Xigou, Shuishiying Street, Lvshunkou District, Dalian City | 100t/d | CWT - A - 100 | | Mobile Sewage Treatment Station in Rural Areas Upstream of Sanya River | 6800t/d | CWT - A - 300, CWT - A - 500 | | Emergency Sewage Project of Yangzhen Reclaimed Water Plant, Shunyi | 3000t/d | CWT - A - 300 | | Sewage Treatment Project in Ziwu Street Community, Chang'an District, Xi'an City | 550t/d | CWT - A - 50, CWT - A - 100, CWT - A - 200 | | Water Affairs Integration Construction Project in Xingyi City | 3800t/d | CWT - A - 200, CWT - A - 300, CWT - A - 500 | | Sewage Treatment Project in Rural Residential Areas of Sihong Townships, Jiangsu | 1850t/d | CWT - T - 50, CWT - T - 100 | | Sewage Treatment Project in Rural Residential Areas of Sihong Townships, Jiangsu | 2420t/d | CWT - A - 50, CWT - A - 100, CWT - A - 120, CWT - A - 200, CWT - A - 300 |

|