| , MAN-18V32/40 Diesel Generator Set Technical Specifications

1 总则/General 1.1 概述/General 150MW电站项目,拟选用MAN公司许可证技术制造的18V32/40柴油发电机组。本协议将作为设计�制�和验收的依据�?/span> 150MW power plant, select 18V32/40 diesel generating set (which is a licencee of MAN) . This agreement is used for design, manufacture and checking. 本协议作为商务合同的一��分,待商务合同签订后,本协议与商务合同同时生效� This agreement as a part of commercial contract, should become effective on the date when the contract has been duly executed. 本协议用中文和英文书写,如有矛盾之处应以中文为准�?/span> This agreement written in Chinese and English, must acc. to Chinese if contradiction occur. 1.2 基本技��要求/ Basic technical specification 满足规范和规�?/span> / Rules and Regulations�?/span> 1) ISO标准 / ISO standard 2) MAN公司标准 / MAN standard 3) 制�厂标�?/span> / manufacturer’s standard 4) 单位:压�?/span>/bar,温�?/span>/�?/span> / Unit: pressure is bar, temperature is �?/span> 5) 铭牌:中英文,铜�?/span> / Name plate: Chinese and English, copper 6) 油漆颜色�?/span>柴油机颜�?/span>/Diesel engine�?/span> Munsell notation:7.5BG7/2 增压器颜色:银色/Turbocharger for main engine�?/span>Silver 防爆安全阀��色:黑色/ Safety valve for crankcase: black 2 发电机组主要技��规格/ Technical specification of Genset 1) 最��持续功率/ Nominal maximum continuous rating: 当柴油机�?/span>720�?/span>/分时,飞轮端输出功率/ Output on flywheel at 720r/min: 9000 kW 发电机接线端子处输出功率/ Output on terminals of alternator: 8730 kW 频率/ frequency: 60 Hz 电压/ voltage: 13.8 kV 以上数据基于环境状况如下/ The output is stated at : 大气压力/ ambient air pressure: 1 bar 冷却水温�?/span>/ cooling water temp. before charging air cooler: 38�?/span> 环境温度/ ambient temperature: 45�?/span> 相对湿度/ relative humidity�?/span>60% 2) 速度变化/ Speed variation�?/span> 瞬�:在10%以内 Momentary: within 10% 稳�:在5%以内 Permanent: within 5% 恢复时间:在5秒钟以内 Recovery time: within 5 sec. 负荷变化�?/span>100%�?%�?3%�?6%�?4%�?00% Load variation: 100%�?%�?3%�?6%�?4%�?00% 3) 燃油: xxcSt@50℃,油品报告见附�?/span>xx(由用户提供�?/span>�?/span>MDO�?/span>MGO �?/span>ISO 8217-2010�?/span>, 燃用MDO�?/span>MGO,低硫燃油时,进机粘度必须大�?/span>2 cSt; 柴油机外部的燃油系统管路中需配置有过滤精度为10μm�?/span>abs)的自清式反冲洗滤器;出厂台架试验时用国产轻柴油�?/span>GB252)� Fuel: xxcSt@50�?/span>, the oil analysis report see attachment xx (supply by owner), MDO, MGO (ISO 8217-2010), When burning on MDO, MGO and low sulphur fuel oil (S�?/span>0.1%), the viscosity at engine inlet must be �?/span>2cSt; An automatic back-flush filter 10μ(abs) must be mounted in the external fuel oil system of the engine; Shop tested running on diesel oil (GB252). 4) 柴油机与发电机�公共底座为弹性连接,发电机刚性安装在公共底座上,公共底座与基础��刚�安装�?/span> Diesel engine is flexible connected with generator and flexible mounted on common plate. Generator is rigid mounted on common plate. The common plate is rigid mounted against foundation. 5) 供货数量: 每项�?/span>xx�?/span> / Delivery number: xx sets per project 3 柴油机特�?/span>/ Engine particular 3.1环境条件/ Reference condition �?/span>1)柴油机在如下环境条件下运行时不需��降功�?/span>/ No de-rating up to stated reference conditions�?/span> 增压器进气温度: air temperature before turbocharger: | �?/span> 45�?/span> | 大气压力�?/span> air pressure�?/span> | �?/span>1bar | 淡水进空冷器(低温侧)温度: cooling fresh-water temperature inlet charge air cooler(LT stage)�?/span> | �?/span> 38�?/span> | 增压器压气机前进气压�?/span> Inlet pressure before compressor: | �?/span> -20mbar | 增压器后排气背压�?/span> Exhaust gas back pressure after turbocharger�?/span> | �?/span>30mbar |

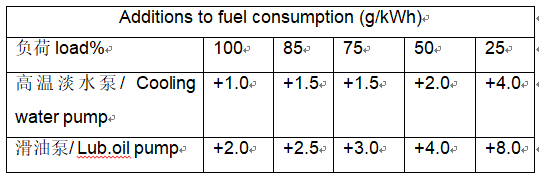

3.2柴油机技术规�?/span>/Technical specification of engine型号 Type | 18V32/40 | 型式 Model | 单作用�四冲程�筒形活塞、直接喷射�增压、中冷�V型�不可逆转中�柴油�?/span> Single acting, 4-stroke, trunk piston, direct injection, turbocharger, charge air cooler, Vee type, not reversal medium speed engine. | 气缸直径�?/span>mm Cylinder bore�?/span>mm | 320 | 活塞行程�?/span>mm Piston stroke�?/span>mm | 400 | 转向 Direction of engine rotation | 顺时针(从飞轮端向自由端看) Clockwise, viewing from flywheel end | 气缸�?/span> Number of cylinders | 18 | 最��持续功率/转� Max. continuous output/rated speed | 9000 kW�?/span>720 r/min | 平均有效压力�?/span>bar Mean effective pressure�?/span>bar | 24.9 | 最��燃烧压力�?/span>bar Max. combustion pressure�?/span>bar | 190 | 燃油规格 Fuel oil specification (注:台架试验上用GB252 0#�?/span>-10#轻柴�?/span>�?/span>/Note :Use GB252 0# or -10# grade diesel oil on shop test.) | 重油,见附件xx�?/span>HFO�?/span>see attachment xx MDO MGO Low sulphur fuel oil | 100%MCR工况下燃油消耗率�?/span>g/(kWh) Specific fuel oil consumption (SFOC) at MCR�?/span>g/(kWh) | 187+5% 1�?/span>2�?/span>3�?/span>4�?/span> | 85%MCR工况下燃油消耗率�?/span>g/(kWh) Specific fuel oil consumption (SFOC) at 85% MCR�?/span>g/(kWh) | 186+5% 1�?/span>2�?/span>3�?/span>4�?/span> | 滑油规格 Lub.oil specification | SAE 40 | 润滑油消耗率�?/span>g/(kWh) Lub.oil consumption�?/span>g/(kW.h) | 0.6+20% | 排放 NOx emission | World Bank 2007/2008 1460 mg/Nm³ NOx | 备注/remark�?/span> 1)燃油消耗率参数基于ISO3046/1 2002标准状况,燃用低热�42700kJ/kg的燃油: The SFOC is given in accordance with ISO 3046/1 2002 condition and using diesel oil with lower calorific value of 42700 kJ/kg: 环境空气温度/intake air temperature: 25�?/span> 环境空气压力/barometric pressure: 1 bar 冷却水进空冷器温�?/span>/ cooling water temp. upstream charge air cooler: 25�?/span> 增压空气进气缸温�?charge air temperature before cylinder: 43�?/span> 相对湿度/relative humidity: 30%. 2)柴油机带泵时,燃油消�率相应增�?/span>/ With built-on pumps, the consumption will be increased by:

3)如果燃�?/span>MGO,油耗增�?/span>2g/(kWh) For operation with MGO, SFOC will increased by 2g/(kWh) 4)排气背压>30mbar,每增加1 mbar �?/span>+0.05 g/kwh Exhaust gas back pressure after TC�?/span>30mbar�?/span>every addition 1 mbar�?/span>+0.05 g/kWh |

4系统参数/system parameter�?/span>�?/span>1)燃油系�?/span>/ Fuel oil system | 燃油品种 Fuel oil specification | 重油�?/span>MDO,MGO,低硫燃油 HFO, MDO, MGO, Low sulphur fuel oil | 燃油进机粘度和温度要�?/span> the viscosity and temperature of fuel upstream of the engine | (1)对于燃油MGO(ISO-F-DMA)�?/span>MDO(ISO-F-DMB),该燃油进机温度不超过45�?/span>,�且该燃油进机粘度不小�?/span>1.9 cSt�?/span> As to MGO(ISO-F-DMA) and MDO(ISO-F-DMB), the temperature of fuel upstream of the engine must not exceed 45�?/span> and the viscosity of fuel upstream of the engine must be at least 1.9 cSt. (2)对于燃油MDO(ISO-F-DMC),该燃油进机温度不超�?/span>60�?/span>�?/span> As to MDO(ISO-F-DMC), the temperature of fuel upstream of the engine must not exceed 60�?/span>. (3)对于生物燃料油,燃油进机粘度大于2 cSt�?/span> As to bio-fuel, the viscosity of fuel upstream of the engine must be over 2 cSt. (4)对于燃油HFO(ISO-F-RM),该燃油进机温度不超�?/span>150�?/span>,�且该燃油进机粘度满足12-14 cSt�?/span> As to HFO(ISO-F-RM), the temperature of fuel upstream of the engine must not exceed 150�?/span> and the viscosity of fuel upstream of the engine must be 12-14 cSt. | 燃油进机压力 the pressure of fuel upstream of the engine | 6~8 bar, Min. 4 bar | 燃油双联安全滤器绝对过滤精度 Fuel duplex safety filter absolute fineness | 25 µm | 供油单元燃油处理精度要求 Fuel treatment fineness (absolute) from the booster module | 10µm |

�?/span>2)滑油系�?/span>/ Lub. oil system | 滑油品种 Lub.oil specification | SAE40 | 滑油进机压力 Lube oil before engine | 4~5 bar | 主机起动前滑油预热温�?/span> Prior to the engine start, the lube oil in the service tank and the system shall be heated up to: | �?/span> 40 �?/span> | 机带滑油�?/span> Lube oil pump, engine driven | 191m3/h, 8 bar | 电动预润滑油�?/span> Prelubrication oil pump, electrical drive | Min. 49 m3/h | 滑油自清滤器 Lube oil automatic filter | 持续反冲洗过滤,1级过滤精�?/span>34μm,二级过滤精�?/span>80μm Continuous flushing, 34μm 1st stage filter, 80μm 2st stage filter. | 吸口滤器 Suction filter | ~ 540 μm | 滑油循环舱(T-001�?/span> Lube oil service tank�?/span>T-001�?/span> | 所��滑油量最低限度是1 L/kW�?/span> The minimum quantity of lube oil for the engine is 1 L/kW. | 预润滑和后润�?/span> Pre-lubrication and post-lubrication | 在柴油机起动前,需��预润滑,即预润滑油泵在柴油机起动前需要运�?/span>5分钟;当柴油机停止运行后,需要对主机进行后润滑,后润滑需要持�?/span>15分钟�?/span> For main engines the prelubrication oil pump is to be put into operation 5 minutes before engine start. The prelubrication oil pumps are also to be used for post-lubrication when the engine is stopped. And post-lubrication is effected for a period of 15 minutes. |

�?/span>3)冷却水系统/ Cooling water system | 高温水出机温�?/span> H.T. water temp. outlet engine | ~ 90 �?/span> | 高温水进机压�?/span> H.T. water pressure inlet engine | 3~4 bar | 机带高温水泵 HT cooling water pump, engine driven | 140 m3/h�?/span>4.5 bar | 高温水预加热单元 Preheating module for HT cooling water | 预加热功�?/span>:最��6 kW/�?/span> 柴油机起动前缸套水预热温�?/span>�?0 �?/span> Heating power: Min. 6 kW/cylinder Before starting a cold engine, it is necessary to preheat the water-jacket up to 60 �?/span>. | 高温水温控阀 HT cooling water temperature control valve, electrical driven | 220V�?/span>50 Hz | 高温冷却水膨胀���?/span> HT cooling water expansion tank | 容积:min. 0.7 m3(单台主机用�?/span> 高度:6~9 m(水箱底部至曲轴中心线) Capacity: min. 0.7 m3 for each engine Height: 6~9 m (from the tank bottom to the crankshaft centre line) | 空冷器低温冷却水进口温度 L.T. water temp. before charge air cooler | Max. 38 �?/span> | 空冷器低温冷却水进口压力 L.T. water pressure before charge air cooler | 2~4 bar | 机带低温水泵 LT cooling water pump, engine driven | 225m3/h�?/span>4.5 bar | 低温水温控阀 LT cooling water temperature control valve, electrical driven | 220V�?/span>50 Hz | 增压空气温控阀/span> Charge air temperature control valve, electrical driven | 220V�?/span>50 Hz | 低温冷却水膨胀���?/span> LT cooling water expansion tank | 容积: min. 0.7 m3(单台主机用�?/span> 高度:6~9 m(水箱底部至曲轴中心线) Capacity: min. 0.7 m3 for each engine Height: 6~9 m (from the tank bottom to the crankshaft centre line) | 油头冷却�?/span> Nozzle cooling water cooler | 1�?/span>/机,包含泵�冷却器�膨胀水箱�?/span> 1 set per engine,inclouding pump,cooler,expansion tank etc. |

�?/span>4)压缩空气系�?/span>/ Compressed and Control air system | 用户提供压缩空气压力 Compressed air supplied by owner | 15�?/span>30 bar | 控制空气压力 Control air pressure | 8bar�?/span>min. 5.5bar | 主机起动方式 Start type | 主机采用压缩空气主启动阀起动;起动空气压�?/span>15�?/span>30 bar�?/span> Main engine started by main start valve and compressed air, compressed air pressure for starting is 15�?/span>30 bar. | 起动空气消�量(柴油机每次起动) Air consumption per start | 2.5 Nm3 | 补气消�量(每次补气�?/span> Air consumption per Jet Assist activation | 5.95Nm3 |

�?/span>5)进排气系统/ Exhaust gas and Charge air system | 进气�?/span> Air mass flow | 63.9 t/h(�?/span>ISO3046标况�?/span>) Under ISO3046 standard condition | 排气�?/span> Exhaust air mass flow | 65.7 t/h(误差±5%�?/span>tolerance ±5%) | 增压器出口处排温 Temperature at turbine outlet | 326 �?/span>(误差±20℃,tolerance ±20�?/span>) | 排气背压 Permissible exhaust gas back pressure after turbocharger | �?0mbar | 增压器压气机前进气压�?/span> Inlet pressure before compressor: | �?20mbar | 涡轮增压�?/span> Turbocharger | NR型,带进气弯头,布置在自由端,用户需在柴油机外部安装进气滤器 NR type�?/span>with intake air elbow, mounted on free-end, the owner must install intake air filter in the external of the engine. | 空气冷却�?/span> Air cooler | 淡水两级冷却 Fresh water 2-stage cooler |

�?/span>6)安全�控制和监控系�?/span>/ Safety, control and monitoring system | 柴油机控制采�?/span>: SaCoSone系统 Engine control system: SaCoSone system | 本地操作屏显示文字:英文 The language of the display for local operating panel: English | 通讯采用MODBUS RS422�?/span>RTU格式 Communication protocols: MODBUS RS422�?/span> RTU | 该系统由可靠性高的和通过认可过的元器件组成,各个模块通过特殊设计用于中�柴油机上。用于柴油机的操作�报警和控制�所��的传感器和控制器件均通过硬线连接到柴油的相关控制单元。然后�过接口柜与电站系统连接� The SaCoSone design is based on high reliable and approved components as well as modules specially designed for installation on medium speed engines.the monitoring and safety system SaCoSone serves for complete engine operation, alarming and control. All sensors and operating devices arewired to the engine-attached units. The wire connection to the power plant is donevia the Interface Cabinet. |

5发电�?/span> / Alternator 1) 品牌: ABB�?/span>VEM 2) 型式: 船用无刷三相交流同步 3) 电压: 13.8 kV 4) 频率: 60 Hz 5) 转�: 720 r/min 6) 功率因数: 0.8(滞后) 7) 功率: 8730 kW 8) 结构形式: 双支撑,滑动轴承 9) 转向: 逆时�?/span>(从发电机驱动端看) 10) 轴承: 双滑动轴承,�?/span>Pt1000温度传感�?/span> (2�?/span>/�?/span>) 和尾端轴承温度计(1�?/span>/�?/span>) 11) 防护等级: IP 23,接线箱�?/span>IP44 12) 冷却方式�?strong>风冷 13) 绝缘等级: F�?/span> 14) 温升等级�?/span>F�?/span> 15) 抗无线电干扰: VDE标准N�?/span> 16) 防冷凝加热器: AC 220 V 17) 定子绕组温度传感�?/span>:2×3×Pt1000�?/span>1套备用) 18) 手动调压电位器(用于配电板上),1�?/span>/机,散件供货 19) 可并联运�?/span> 20) 自动电压调节�?/span> 21) 电缆出线方向和出线填料函规格待定 22) 提供冷却水泄露报�?/span> 23) 提供差动电流互感器,6�?/span>/机(3个装机,3个装MSB�?/span> 1) Brand: ABB or VEM 2) Mode: Marine-use brushless three-phase synchronous 3) Voltage: 13.8 kV 4) Frequency: 60 Hz 5) Speed: 720 r/min 6) Power factor: 0.8 lagging 7) Power: 8730kW 8) Type of construction: two bearing, sleeve bearing 9) Rotation: anti-clockwise (seen form alternator driven end) 10) Bearing: Double sleeve bearing, with temperature sensor Pt1000�?/span>2pcs/alternator�?/span>and counter coupling side bearing temperature thermometer(1pc/alternator) 11) Degree of protection: IP23, terminal box:IP44 12) Cooling type: Fresh air cooling 13) Insulation: F class 14) Temperature rise : F class 15) Radio interference suppression: N (VDE standard) 16) Anti-condensation heater: AC 220V 17) 2×3 Pt1000 sensors in stator-winding (1 set is spare) 18) Manual voltage regulator for switchboard mounting, 1set/engine, loosely supply 19) Parallel running 20) Automatic voltage regulator (AVR) 21) Cable glands to be confirmed by owner 22) With cooling water leakage alarm 23) Differential current transformer :6ea/alternator(3ea: mounted on alternator, 3ea: mounted on MSB)

|