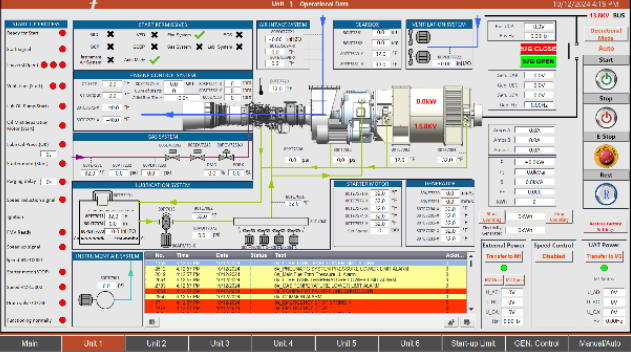

| HMI Interface (REFERENCE ONLY)

ž Data Storage: collect and store the operation data to know about the running tendency of all systems and record the problems;

ž Voltage Regulation: regulate the voltage and frequency automatically and manually in HMI; 15.0 PAINT Equipment shall be free from any obvious defect. Coating shall be medium durable and meet inland operation environment conforming to ISO-12944 Paints and Varnishes-Corrosion Protection of Steel Structures by Protective Paint Systems (C4- high). Painting color will be subject to customer’s requirement. 16.0 DOCUMENTATION The maker will furnish one (1) hard document copy and one (1) electronic copy in English per Unit of the operation and maintenance manuals containing the following: • Layout drawing • Lubrication schematic with parts list • Gas fuel schematic with parts list • Instrument air schematic with parts list • Electrical schematic with wiring diagram and parts list • Operating/Maintenance manuals Annex 1: Gas Fuel Specification GAS FUEL SPECIFICATION FOR THE SGT-AQ5 Table 1 and Table 1a provide the nominal gas fuel specifications for the SGT-A05 non-DLE and DLE combustion systems, respectively. Consult the utility consumption list and fuel system data provided in the Operation and Maintenance (O&M) manuals for specific details on your SGT-A05 package. Gas fuel properties are provided under standard conditions: 15°C (59°F) and 101.325 kPa (14.696 psia). Contact Siemens Energy if you have any questions about the fuel specification or the fuel source and supply conditions for your gas turbine. Parameter | Requirement | Lower Heating Value (LHV) | 600 - 2000 BTU/SCF (22.4 - 74.5 MJ/m3) * | Specific Gravity | ~0.6 nominal | Wobbe Index: Lower Heating Value/ √Specific Gravity | 1040 -1300 (BTU/SCF) (38.8 - 48.4 MJ/m3) | Gas Fuel Constituent Limits- see Notes 2, 15 | Pentane (C5Hx) content | 0.5 mole % max* | Hexane/Benzene (C6Hx) content | 0.5 mole % max* | Heptane (C7+Hx) + content | 0.5 mole % max* | Hydrogen (H2) content | 10 mole % max* | Water Vapor (H2O) content | 0.2 mole % max | Hydrogen Sulfide (H2S) content | 0.05 mole % max | Sulfur Dioxide (SO2) content | 0.05 mole % max | Liquid hydrocarbons content | None | Ice-forming moisture content | None | Contaminant Limits - see Note 10 | Sulfur content | Contact Siemens Energy.(See Notes 4, 5, 6, 7, 8) | Vanadium content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Sodium and potassium content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Calcium content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Lead content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Zinc content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Copper content | 1.09E-5 lb/106 BTU (4.67E-3 mg/MJ) max | Iron content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Chlorine content | 4.14E-5 lb/106 BTU (1.71E-2 mg/MJ) max |

|

| Magnesium content | 8.14E-5 lb/106 BTU (3.50E-2 mg/MJ) max |

|

| Filtration Requirement - see Notes 10,15 | Particulate Content |

| Greater than 3 microns | None | Less than 3 microns | 1.4E-4 lb/106 BTU (6.14E-2 mg/MJ) | Liquid Droplet Content |

| Greater than 8 microns | None | Less than 3 microns | Droplets smaller than 8.0 microns are expected to be uniformly distributed in the gas and vaporized in a superheater before entering the engine. See Temperature above. | Supply Conditions - see Notes 2f 3f 13,14,16,17,18 | Pressure | 270 - 280 psig (1862- 1931 kPa) at the Fuel Metering Valve Inlet | Temperature | 200°F (93°C) maximum. Fuel must be 20°F (11°C) above its dew point at the supplied pressure. SEI recommends a minimum fuel supply temperature of 32°F (0°C). |

|

|

|

**The specified value may be able to be relaxed under some conditions. Contact Siemens Energy to discuss or seek approval for any deviations to the requirements above. Table 1a Gas Fuel Specification for the SGT-A05 DLE Fuel System

Parameter | Requirement | Lower Heating Value (LHV) | 800 -1000 BTU/SCF (29.8 - 37.3 MJ/m3) | Specific Gravity | ~ 0.6 nominal | Wobbe Index: Lower Heating Value/√Specific Gravity | 1040 -1300 (BTU/SCF) (38.8 - 48.4 MJ/ m3) | Gas Fuel Constituent Limits- see Notes 2,15 | Ethylene (C2H4) content | 1 mole % max | Ethane (C2H6) content | 10 mole % max | Propane (C3H8) content | 50 mole % max* | Butane/Butene (C4Hx) content | 1 mole % max* | Pentane (C5Hx) content | 0.25 mole % max* | Hexane/Benzene (C6Hx) content | 0.25 mole % max* | Heptane (C7+Hx) + content | 0.25 mole % max* | Hydrogen (H2) content | 1 mole % max* | Water Vapor (H2O) content | 0.1 mole % max | Hydrogen Sulfide (H2S) content | 0.05 mole % max | Sulfur Dioxide (SO2) content | 0.05 mole % max | Liquid hydrocarbons content | None | Ice-forming moisture content | None | Contaminant Limits - see Note 10 | Sulfur content | Contact Siemens Energy. (See Notes 4, 5, 6, 7, 8) | Vanadium content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Sodium and potassium content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Calcium content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Lead content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Zinc content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Copper content | 1.09E-5 lb/106 BTU (4.67E-3 mg/MJ) max | Iron content | 2.72E-5 lb/106 BTU (1.17E-2 mg/MJ) max | Chlorine content | 4.14E-5 lb/106 BTU (1.71E-2 mg/MJ) max | Magnesium content | 8.14E-5 lb/106 BTU (3.50E-2 mg/MJ) max | Filtration Requirement - see Notes 10,15 | Particulate Content |

| Greater than 3 microns | None | Less than 3 microns | 1.4E-4 lb/106 BTU (6.14E-2 mg/MJ) | Liquid Droplet Content |

| Greater than 8 microns | None | Less than 3 microns | Droplets smaller than 8.0 microns are expected to be uniformly distributed in the gas and vaporized in a superheater before entering the engine. See Temperature above. | Supply Conditions - see Notes 2, 3, 13, 14, 16,17, 18 | Pressure | 270 - 280 psig (1862- 1931 kPa) at the Fuel Metering Valve Inlets | Temperature | 200°F (93°C) maximum. Fuel must be 20°F (11°C) above its dew point at the supplied pressure. SEI recommends a minimum fuel supply temperature of 32°F (0°C). |

NOTE The SGT-A05 Gas Fuel specification is dependent on the combustion system configuration. Table 1 above contains the specification for the non-DLE combustion system. *The specified value may be able to be relaxed under some conditions. Contact Siemens Energy to discuss or seek approval for any deviations to the requirements above. NOTE 1 Non-turbine fuel system components can change this limit. Refer to the Operation and Maintenance (O&M) manual for details. NOTE 2 As the proportion of heavy hydrocarbons in gas fuel increases, the fuel supply temperature should be increased to maintain the fuel in a gaseous state at a given pressure. To ensure the fuel remains in a gaseous state, measure the composition of the fuel gas regularly. The terms "ethane and heavier" and "hexane and heavier" refer to fuel gas constituents comprising only carbon and hydrogen. Limits on these constituents have been set to minimise the likelihood of auto-ignition in DLE systems. Limits have been set for hydrocarbons that belong to the alkane group, such as ethane, for all combustion systems. If you intend to use gas fuel containing any other constituents, contact Siemens Energy for a site-specific assessment. Siemens Energy AGT products can run on gas fuel containing up to 25% hydrogen by volume, depending on gas composition. If you intend to use gas fuel that contains more than 15% hydrogen by volume, contact Siemens Energy for a site-specific assessment NOTE 3 Gas fuels that contain inert gas usually need to be supplied at a higher flow and delivery pressure to meet expected performance levels. If you intend to use a gas fuel that contains inert gas levels above the specified limit, contact Siemens Energy for a site-specific assessment. NOTE 4 The hot section of a gas turbine is prone to hot corrosion when such contaminants as sulphur, salt and trace metals enter the gas turbine. Coatings have been applied to several hot section components to reduce their vulnerability to hot corrosion. NOTE 5 Sulphur enters the turbine via gas fuel in the form of hydrogen sulphide (H2S) or sulphur dioxide (SO2). The presence of sulphur can lead to sulphidation of hot section components (a form of high temperature hot corrosion), that will reduce the service life of the gas turbine. Monitor sulphur levels with regular measurement of the composition of the gas. An increase in sulphur that enters the gas turbine will increase SOx emissions. NOTE 6 Air quality and the quality of the water used in the water injection system (if applicable) have a significant effect on the service life of a gas turbine. Air and water quality requirements can be provided by Siemens Energy. NOTE 7 The limit for sulphur and other contaminants (such as trace metals) is the maximum that is allowed to enter the gas turbine through the gas fuel, intake air and injected water (if applicable). Limits specified individually for gas fuel, air and injected water must also be observed. NOTE 8 Overhaul intervals are based on the operation conditions that follow: ž Clean, sulphur-free air that contains very low levels of salt (�?.001 wppm NaCI). ž Clean gas fuel: �?0.027% vol H2S + SO2 with no other fuel contaminants. Or ž Clean sulphur-free air that contains salt (�?.01 wppm NaCI). ž Clean gas fuel: �?0.0005% vol H2S + SO2 with no other fuel contaminants. NOTE 9 Oil or other liquid hydrocarbons in the gas fuel can cause large variations in heat input. In severe cases, slugs of liquid can accumulate in the fuel system that damages the combustor. Accumulation or condensation of oil and other liquid hydrocarbons is not permitted in the fuel system. NOTE 10 Contaminants in the gas fuel can lead to auto-ignition of the fuel that risks damage to the gas turbine. Auto ignition can also cause the gas turbine to shut down. To prevent such problems, installation of coalescer filters is mandatory on standard gas turbine packages. Such coalescer filters should be approved by Siemens Energy. NOTE 11 Sodium and potassium can enter the gas turbine via the fuel and through the air intake in the form of salts. The amount of sodium and potassium that enters the gas turbine influences the rate of sulphidation of hot section parts. The service life of gas turbine components can be significantly reduced in environments containing high levels of sodium and potassium, such as marine environments. NOTE 12 The limit for sodium plus potassium is the maximum that is allowed to enter the gas turbine through the gas fuel, intake air and injected water (if applicable). The limit is based on fuel with a lower calorific value of 42.6 MJ/kg (18,315 Btu/lb).

NOTE 13 Site-specific gas fuel supply conditions, as stated in the contractual agreement, apply. If the gas fuel properties or supply conditions change, contact Siemens Energy so that operation parameters can be re-evaluated. NOTE 14 Gas fuel that enters the fuel skid must be maintained at a temperature that allows for the fuel to cool between the fuel skid and the fuel injector outlet. NOTE 15 As the proportion of water in gas fuel increases, the fuel supply temperature should be increased to maintain the fuel in a gaseous state at a given pressure. To ensure the fuel remains in a gaseous state, measure the composition of the fuel gas regularly. NOTE 16 The fuel supply temperature must be controlled to make sure that the fuel is kept in a gaseous state and fuel system components (such as fuel valves) remain in good condition. NOTE 17 The fuel supply temperature limit is governed by the parts in the fuel delivery system with the lowest limit of operation. NOTE 18 The fuel supply pressure limit is governed by the parts in the fuel delivery system with the lowest limit of operation. NOTE 19 Fuel supply pressure fluctuations must be avoided to ensure stable operation. Fuel pressure fluctuations at frequencies of up to 1000 Hz can cause oscillations in some components. In severe cases such fluctuations can lead to component failure. Step changes in fuel pressure are acceptable if a fuel booster is used. The Engine Control System (ECS) will accommodate the new stable fuel pressure. NOTE 20 Non-turbine fuel system components can change this limit. Refer to the O&M manual for details. NOTE 21 Fuel supply pressure fluctuations must be avoided to ensure stable operation. Fuel pressure fluctuations at frequencies of up to 1000 Hz can cause oscillations in some components. In severe cases such fluctuations can lead to component failure. A fuel pressure variation of ±0.4% is the maximum allowed for all SGT-A35 operation conditions. A fuel pressure variation of ±0.2% is the maximum allowed for all SGT-A45 and SGT-A65 operation conditions. Step changes in fuel pressure are acceptable if a fuel booster is used. The Engine Control System (ECS) will accommodate the new stable fuel pressure. NOTE 22 Overhaul intervals are based on the operation conditions that follow: • Clean, sulphur-free air that contains very low levels of salt (�?0.001 wppm NaCI). • Clean liquid fuel: �?0.05 wt.% sulphur, �?0.1 wppm sodium, �?0.1 wppm potassium, �?0.1 wppm calcium, �?0.1 wppm magnesium with no other fuel contaminants. Or • Clean sulphur-free air that contains salt (�?0.01 wppm NaCI). • Clean liquid fuel: �?0.005 wt.% sulphur, �?0.1 wppm sodium, �?0.1 wppm potassium, �?0.1 wppm calcium, �?0.1 wppm magnesium with no other fuel contaminants. NOTE 23 The limit for sulphur and other contaminants (such as trace metals) is the maximum that is allowed to enter the gas turbine through the liquid fuel, intake air and injected water (if applicable). Limits specified individually for liquid, air and injected water must also be met. NOTE 24 The limit for trace metals is based on fuel with a Lower Calorific Value (LCV) of 42.6 MJ/kg (18,315 btu/lb). To account for changes in LCV, the limit must be scaled as follows: Limit = 0.5 wppm x LCV (MJ/kg) 142.6 MJ/kg NOTE 25 The hot section of a gas turbine is prone to hot corrosion when contaminants such as sulphur, salt and trace metals enter the gas turbine. Coatings have been applied to several hot section components to reduce their vulnerability to hot corrosion.

NOTE 26 All distillate fuels contain sulphur. The presence of sulphur can lead to sulphidation of hot section components (a form of high temperature hot corrosion), that reduces the service life of the gas turbine. NOTE 27 Sodium and potassium can enter the gas turbine via the fuel and through the air intake in the form of salts. The amount of sodium and potassium that enters the gas turbine influences the rate of sulphidation of hot section parts. The service life of gas turbine components may be significantly reduced in environments that contain high levels of sodium and potassium, such as marine environments. NOTE 28 Air quality and the quality of the water used in the water injection system (if applicable) have a significant effect on the service life of a gas turbine. Air and water quality requirements can be provided by Siemens Energy.

Suggested test standards and methods to determine the properties and condition of gas fuel are provided in Table 5. The latest versions of these standards apply. The information provided in Table 5 is not exhaustive; other standards are available. Contact Siemens Energy if you require further advice. Table 5 Test Methods and Standards for Gas Fuel Properties Property | Test Method/Standard | Natural gas sampling guidelines | ISO 10715 | Natural gas standard reference conditions | ISO 13443 | Natural gas quality designation | ISO 13686 | Lower Calorific Value (LCV), Wobble Index | ISO 6976, ISO 15112, ISO 15971, ISO/TR 29922, ASTM D4891 | Gas fuel constituents, including hydrocarbons, N2 and CO2 | ISO 6974, ISO 6975, ISO 11150 ASTM D1945, ASTM D6968, ASTM D4984, ASTM D2650 | Sulphur content, including H2S and SO2 | ISO 6326, ISO 16960, ISO 20729 ASTM D5504, ASTM D6228, ASTM D6968, ASTM D4810, ASTM D4804, ASTM D1072 | Fuel supply conditions | Water content | ISO 10101, ISO 18453, ASTM D5454, ASTM D1142 | Water dew point | ISO 6326, ISO 6327, ISO 18453, ASTM D1142 | Hydrocarbon liquid content | ISO 6326, ISO 6570 | Hydrocarbon dew point | ISO/TR 11150, ISO 23874 |

|