| Company Profile Modern entity enterprise that includes research and development, production, sales, after-sales departments. We already developed and produced the suitable equipments for the organic fertilizer and bio organic fertilizer production, such as the compost equipment, drying equipment, granulating equipment, screening systems and batching systems, and a full set of fertilizer equipment. Our company has strong technical strength, high-q Voltage: 380V, 3 phase, 50HZ(Accept custom) Capacity:10-15 T / H Abby31202412010009-98402 Item | Power | Quantity |

| Fermentation Machine | 40KW | 2set |

| Crush-Screening line | 91kw | 8 Sets |

| Granulating line | 350.62KW | 30 Sets |

| Fob Qingdao Cost need 14 40 HQ container | 14sets |

| Total FOB Qingdao Cost | 481.62KW | 39 Sets |

|

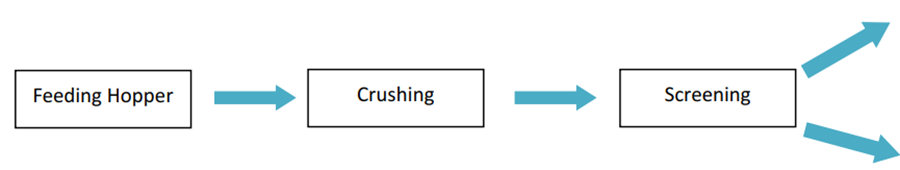

Production time:30-40 working days after get deposit. Machine warranty:1 year(don’t contain Wearing parts) Note: Dryer machine, Cooler machine will connect with Hot stove, Dust Collector room with pipes, pipes length will be calculated and add in quotation after designed the drawing. Seller will supply the cable layout Organic fertilizer granulating plant include 3 areas: 1), Raw material compost area Necessary composting and fermentation process will Kill harmful microorganisms and eggs.According to different material and climate, compost time is with 10-25 days. 2), Raw material preparation area: Raw Material Preparation Area Production Flow: The material before granulating should be fine powder, without impurity, such as wood branch, stone, glasses, fabric..................... …and so on. So, please use the loader take the material after finish fermentation into the feeding hopper, after crushing,screening, and get the fine powder shape raw material, like follow flows:

| Separating the impurity material. | | Separating the fine compost fine powder material for granulating |

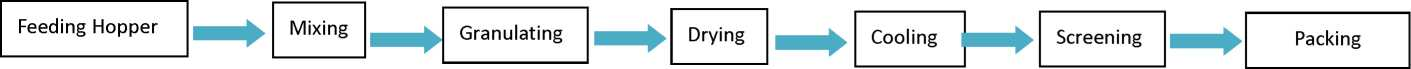

3), Organic fertilizer Granulating Area: Organic fertilizer granulating area production flow: The granulating technology belong to wet granulating technology. After screening, the finished size organic fertilizer granules into packing hopper for packing.The big granules will be crushed into powder, and then together with the fine powder after screening, back to mixing for re-granulating.

You will add other additive material to promote the quality of organic fertilizer finally.So, we have to consider the formula, and use the batching system in the beginning of line. And then mixing(Promoting the moisture to 40%-45%), granulating, drying, cooling, screening, packing.

After screening, the finished size organic fertilizer granules into packing hopper for packing. The big granules will be crushed into powder, and then together with the fine powder after screening, back to mixing for re-granulating.

1, Fermentation Area Flat Drawing(just for reference): Turner machine can prevent compost temperature too high.You can add water or strain when ferment,it also can mixing material when turning.

Wheel Type turner machine This type turner machine can turning material compeletely. Turning machine can prevent compost temperature too high which will kill the organic matters. And the groove type turning machine can save workshop size,the workshop can be more clean. The raw material will move about 2-3 meters after turning one time. Turning height:1.8-2 meters

Turner machine can prevent compost temperature too high.You can add water or strain when ferment,it also can mixing material when turning. This type is Crawler type turner machine.

Crushing Area 3D Drawing After compost, the material may caked together, so need the crushing machine to make the cake material to powder. Some material may cannot be fertilizer, like the stone, plastic, need screen machine to screen them out.

10 -15 tons/hour Organic Fertilizer Production Line Machines List Date: 2024-12-03 No.: HQHI-Q2024120301 NO. | Commodity | Picture | Model | Power (Kw) | Specification | QTY (Set) | EXW Price (USD/Set) | Fermentation Area: | 1 | Wheel type turner Machine |

| FW11 | 30+1.5*4+4 | Wheel Type turner machine Width : 11000 mm. Turning motor:30kw Walking motor:1.5kw x 4 Hydraulic motor:4kw With PLC electric control box. With one rail cart. Material tank height about 2.1m (don’t contain guide rail and installation accessories) | 1 |

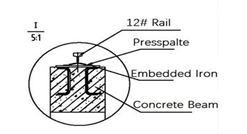

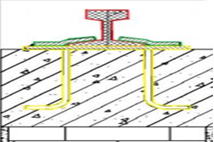

| 2 | Guide rail |

| #22 rail, | / | weight is 22kg per meter. 8 meter per pc.

| 60 pcs |

| 3 | Rail Splint |

| / | / | 1,Connecting per two rail sections 2,Fixing 1 pair per one section of rail | 55 pcs |

|

4 | Embedded Iron |

| / | / | Install 1 pic per 1.5m concrete beam | 324 pcs |

| 5 | Press plate |

| / |

| 1,Pressing the rail on embedded Iron 2,Fix 1 pair per 1.5m length rail | 648 pcs |

| 6 | Crawler turner machine |

| 3000 | / | Width of pile:3000mm Height of pile:900-1200mm 6105/-110KW/140hp Maximum Rotational Speed: 2200 revs per min. Rated Horsepower Speed: 2200 revs per min. Working Speed: 10-50 m/min. Liquid Tank: Have, with spray system Three forward gears, A reverse Production capacity: 1000-1500m3 per hour Overall Dimensions:4200*2700*3000mm | 1 |

| Total |

|

|

| 2sets machine |

| Installation accessories can be purchased according to the actual needs of the customer's factory |

Crushing Area: | 1 | Loader Feeding Hopper |

| 2000*3000 | 3kw+4kw | 1.Function: feeding the materials with loader; 2.Capacity: 1015tons/hr 3.Material Spec: Q235 steel; 4.Structure Characteristics: with belt conveyor and broken device; 5.Weight: 1.44tons 6.Size: 3.8*2.2*2.93m | 1 |

| 2 | Semi-wet Material Crusher |

| BSFS-110 | 55kw | 1.Function: after composting, crusher the compost materials into fine powder; 2.Capacity: 10-15tons/hr 3.Material Spec: Q235 steel; 4. Structure Characteristics: with long and short blades; 5.Weight: 1.8tons 6. Size: 2.27*1.25*1.7m | 1 |

| 3 | Rotary Screening Machine |

| GS1.8*6 | 7.5kw | 1.Function: small stones, plastics, glass slag and other are separated from the fine powder; 2.Capacity: 10-15tons/hr 3.Material Spec: Q235 steel; 4.Structure Characteristics: with rubber beating device(to prevent blocking) and stainless steel screen; 5.Weight: 2.7tons 6.Size: 7.6*2.15*3.4m | 1 |

|

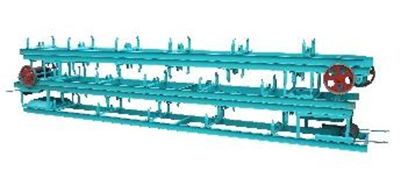

4 | Belt Conveyor |

| B800 (total length:40m) | L=7m*2; 4kw*2 L=11m; 5.5kw L=6m;4kw L=9m;4kw | 1.Function: conveying the materials; 2.Capacity: 10-15tons/hr 3.Material Spec: national standard 120mm channel carbon steel; 4.Rubber belt width: 800mm; 5.V-belt driving type, with safety cover; | 5 |

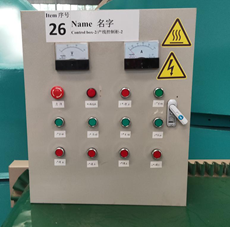

| 5 | Electric Control Box |

| EC-22 | / | Function: control all the power motors of the crushing area production line; | 1 |

|

| If you want the powder material, you can use the above line. The cost will lower. If your raw material already fine powder, you can reduce this steps too. |

| Total |

| 91kw |

| 8 Sets |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Granulation Area: |

| NO. | Commodity | Picture | Model | Power

(Kw) | Specification | QTY

(Set) | EXW Price

(USD/Set) | 1 | Batching

machine |

| BP-500 | 1.1Kw*5 | 1.Function:Practicing automatic continuous batching

process according to customer’s formula. Dosing Error:

+ 0.5%.

2.Machines Composition:

2.1, 5 sets of feeding hoppers

2.1.1,Hopper size: 1.5*1.5m, Volume:1.5m CBM.

2.1.2,Hopper material: 3mm thickness Q235 carbon

steel.

2.2, 5 sets of weighing belt conveyors

2.2.1,Each weighing belt conveyor with 1 pic of rotary

encoder and 1 pic of weighing sensor(weighing

range:100Kgs)

2.2.2,Weighing conveyor length:2.0m

Weighing conveyor width:0.5m,

Weighing Conveyor Power: 1.1kw/set.

2.3, 1 set of HMI general control cabinet

2.3.1, Electrical device: Schneider Electric Device

3.Operation Instruction:

3.1, 1 labor feed 1 hopper, totally need 4-5 labors.

3.2, The batching process is finished automatically.

4,Feeding capacity: 5-30 t/h | 5 |

|

| 2 | Double Shafts Mixer |

| ZYQ-400 | 11kw | 1.Function: make the different solid material and liquid mixing evenly; 2.Capacity: 10-15tons/hr 3.Material Spec: Q235 steel; 4 .Structure Characteristics: with double shafts blend paddle and blades inside; 5.Weight: 1.2tons 6.Size: 4.25*1.35*1.15m | 1 |

|

|

| 3 | Uniform Feeder |

| 1.5m*1.5m | 3kw | 1.Function: store materials to make them evenly feed; 2.Capacity:10-15tons/hr 3.Material Spec: Q235 steel; 4. Structure Characteristics: with screw conveyor; 5.Weight: 500kgs 6.Size: 1.8*1.6*1.6m | 1 |

|

|

| 4 | Combined New Type Organic Fertilizer Granulator |

| YSL2-1000/15 00 | 75kw+11kw +18.5kw | 1. Function: it is a new type of combined granulator suitable for big capacity. It combines the stirring granulation and rotary drum granulation, with former stirring and latter rotating drum; 2.Capacity: 10tons/hr 3.Material Spec: Q235 carbon steel; 4. Structure Characteristics: with many stirring inside; 5.Weight: 7.8tons 6.Size: 5.95*2.15*2.35m | 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 | Ball Shaping Machine |

| PYS1500-3 | 15KW*3 | 1. Function: make the granules more round 2.Capacity: 10-15tons/hr 3.Material Spec: Q235 steel; 4.Structure Characteristics: 5.Weight:2.35t 6.Size: 4.9*1.65*1.9m | 1 |

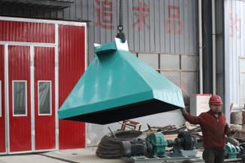

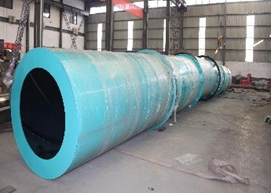

| 6 | Rotary Dryer |

| HG2.0*20 | 30kw | 1.Function: reduce the moisture of the granules, also have the second granulating function; 2.Capacity: 10-15tons/hr3.Material Spec: Q235 steel; 3.Structure Characteristics: with 1 set of seal head; 1 set of seal tail; 1 set of drying body with gear rolling and rolls;2 sets of roll bearing base;1 set of driving base;1 pc of hot air pipe; and 2 pcs of straight air pipe; and 1 pc of elbow; 5.Diameter: 2.0m;Length:20m;Steel thickness:16mm 6.Weight: 23.3tons 7.Size: 22.1*2.8*2.47m Remark: the rotary dryer is with the temperature couples and temperature display system. | 1 |

| 7 | Rotary Dryer Hot Air Fan |

| 12C | 37kw | 1.Function: Inducing the hot air from the hot air stove, and through the dryer machine body, pass the hot air fan, and through the dust collecting room, and end from the chimney . | 1 | / |

8 | Rotary Cooler |

| LQ18180 | 22 kw | 1 .Function: cooling the fertilizer granules to normal temperature; 2 .Capacity: 10-15 tons/hr 3 .Material Spec: Q235 carbon steel; 4 .Structure Characteristics: with 1 set of head; 1 set of drying body with gear rolling and rolls; 2 set of roll bearing base;1 set of driving base;1 pic of straight pipes; and 1 pics of elbow; 5.Diameter: 1.8m;Length:18m;Steel thickness:12mm 6.Weight: 13tons 7.Size: 18*1.81*1.81m | 1 |

| 9 | Rotary Cooler Air Fan |

| 6C | 22kw | 1 .Function: Inducing the normal natural air, through the cooler machine body, pass the cooler air fan, and through the dust collecting room, and end from the chimney . 2 .Air flow:17463-32380m3/hr Air Pressure:2478-1816Pa | 1 | / | 10 | Rotary Screening Machine |

| GS1.8*6 | 7.5kw | 1.Function: small stones, plastics, glass slag and other are separated from the fine powder; 2.Capacity: 10 -15tons/hr 3.Material Spec: Q235 steel; 4.Structure Characteristics: with rubber beating device(to prevent blocking) and stainless steel screen; 5.Weight: 2.7tons 6.Size: 7.6*2.15*3.4m | 1 |

|

11 | Coating Machine |

| BM1.5*6.0 | 5.5kw | 1.Function: coating anti-caking or bacterial species; 2.Capacity:10-15tons/hr 3.Material Spec: Q235 steel; 4.Structure Characteristics: with PVC or rubber lining board, 1 pc of gear roll and 1 rolls;1 set of driving bearing cast base, 2 sets of roll bearing cast base; 5.Diameter: 1.5m; Length:6.0m; Steel thickness:12mm 6.Weight: 4.45tons 7.Size: 6.0*1.9*1.9m | 1 |

| 12 | Packing Hopper |

| 1.5*1.5 | / | 1.Function: store the finished fertilizer granules for packing machine; 2.Capacity: 1.5m3 3.Material Spec: Q235 steel; | 1 |

|

| Air Compressor |

| / | 2.2kw | Function: provide are pressure for the air pump on the packing machine; | 1 |

|

14 | Packing Machine |

| DCS-25 | 0.55kw+0.3 7kw | 1.Packing machine parts: (1) Packing machine body (2) Sewing Part (3) Belt Conveyors (4) Air Compressor 2.Packing range: 25-50kgs/bags 3.Packing bags size: >= Diameter: 300mm 4 .Granules packing speed: 8-10 bags/ Min( In theory), 4-6 bags/Min( In practice) 5.Motor: (1) Sewing motor 0.37kw (2) Belt conveyor motor 0.55kw (3) Air compressor motor 2.2kw 6.Packing Machine Panel Electric: 220-240v, 1 phase, 50hz | 2 |

| 13 | Chain Crusher |

| LP600 | 11kw | 1 .Function: crushing the big granules from the third output of rotary screening machine into power shape for re-granulating; 2 .Capacity: 1-3tons/hr 3 .Material Spec: Q235 steel; 4 .Structure Characteristics: with chains crushing blades inside; 5.Weight: 0.35tons 6.Size: 1.0*0.98*1.55m | 1 |

|

Note: The quantity of containers and the sea freight are for reference only (the sea freight is updated every half a month). The final quantity and price shall

be subject to the final confirmed machines quantity and the latest sea freight price. |

14 | Belt Conveyor |

| B800

(total

length:95m) | L=7m;4kw L=10m;4kw L=14m*2;

5.5kw*2 L=5m;4kw L=11m;5.5kw L=9m;4kw L=12m;5.5kw L=13m;5.5kw | 1.Function: conveying the materials;

2.Capacity:10-15tons/hr

3.Material Spec: national standard 120mm channel

carbon steel;

4.Rubber belt width: 800mm;

5.V-belt driving type, with safety cover; | 9 |

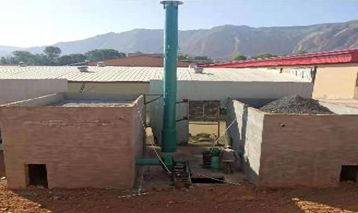

| 15 | Chimney |

| Ø900

H=9m | / | 1.Function: smoke exhaust;

2.Material Spec: Q235 steel;

3.Blow ground level: ø1100mm

Above ground level: ø1000mm

Height: 9m

Steel thickness: 6mm | 1 |

| 16 | Electric

Control Box |

| EC-22 | / | Function: control all the power motors of the

granulation area machines; | 1 |

| Total |

|

| 350.62KW |

| 30 |

|

1,All machines motors and electric control device are with 380v,3phase,50hz, 2,Rotary dryer and Rotary cooler air pipes: 1),The rotary dryer is with the Temperature Couplers and Temperature Display System. 2),The rotary dryer stove’s hot source in this quotation choose oil or gas as the fule. The rotary dryer stove’s hot source can also be built by the customer-self, the seller provide the construction drawing. The fuel is coal and biomass pellets. 3, The production line above doesn’t include: 1) The bracket steel for the batching system feeding hoppers, belt conveyor, dryer seal head and seal tail, cooler seal head, and packing silo. 2) The cables for connecting electric and all machines motors. 3) Assembly tools, such as welding machine, cutter, elevator, forklift, and so on. If the customer need us provide the parts above, the seller need make another quotation for the parts above. 4,The necessary constructions are as follows: 1), The foundation base for the organic fertilizer granulator, dryer, and cooler 2), Construction for the dust collecting room, fire stove 3), Electric cables groove for the production line.(It’s optional) 4), Control system rooms. After make deal, the seller will provide the construction drawings for the above. 5,Delivery Time:

6,Installation Term: 1), The customer finish the installation service by themselves, the seller provide all detailed assembly drawings.

Rotary Dryer | Hot Air Fan/ Cooler Air Fan | Rotary Cooler |  |  |  | Belt Conveyor | Packing Machine | Electric Control Cabinet |  |  |  |

|