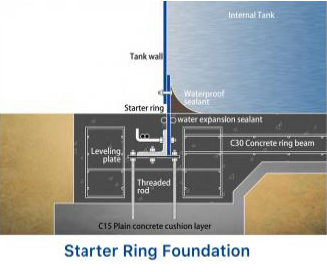

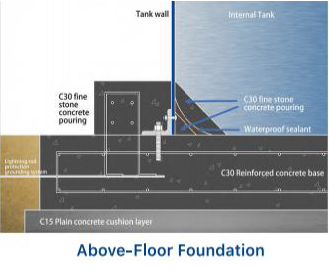

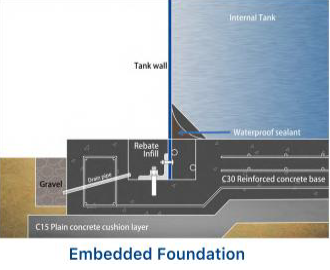

| The issues that need to be addressed to customers are as follows: 1. Type of raw material (sewage, animal waste, kitchen waste, or other) 2. If it is breeding sewage, such as pig farms, you need to confirm the manure cleaning method with the customer (dry manure or water flushing manure) 3. If it is industrial sewage, municipal sewage, you need to ask the customer for the water quality report (Influent waterparameter/Inflow test report) 4. Effluent water parameters/Emission standards 5. Is there any restriction on the land available for the project? If so, please give the scope of the land available 6. If it is a possible biogas project, ask the customer about the utilization of biogas. Generally, palm oil wastewater and some COD (above 8000-9000) wastewater can produce biogas. It is said that urban domestic sewage, aquaculture sewage, biogas can generate electricity and burn boilers, etc. 6. If it is a possible biogas project, ask the customer about the utilization of biogas. Generally, palm oil wastewater and some COD (above 8000-9000) wastewater can produce biogas. It is said that urban domestic sewage, aquaculture sewage, biogas can generate electricity and burn boilers, etc. TANK KIT AND ACCESSORIES • Glass-Fused-to-Steel sheets • Self-locking bolt (HDG) with PP cap, nut, washer, including 3% backup • Silicon sealant, waterproof sealant • HDG top&bottom angles, HDG wind wind girder (stiffener) • Access vertical; ladder with safety cage and platform 1M x 1M (HDG) • 1*DN600 manway, nozzles designed according to file DESIGN CRITERIA Design Code: AWWA D103-09, OHSA, EN/ISO 28765, EURCODE Application: Biogas plant turnkey project Wind load: 100mph Snow load: 15psf Seismic Zone: Zone 4 acc. AWWA Fluid Temperature: -5~ 75 Degree C. PH Range: 3~11 Specific Gravity: 1 Operation temperature: Ambient Pressure: 3500PA (enamel roof), 500~1000PA (membrane roof) Vacuum: -500PA( enamel roof), -200PA (membrane roof) Edge Protection: Enameled edge Panel Bolts: HDG bolt with PP capped Foundation Type: Embedded TANK SPECIFICATION Standard Color: Dark Blue (RAL 5004), Dark Green (R6006L) Coating Thickness: 230 mircon ~480 micron Steel Size: 2400 x 1200mm Steel thickness: 3 - 12mm Adhesion: 3,450 N/cm2 Hardness: 6.0 Mohs Service Life: 30 Years Holiday test: 1500 V QUOTATION CONDITIONS • Quotation includes above-mentioned accessories, for any further special accessories/design demands, quotation needs to be revised accordingly. • Concrete foundation, waterproof construction, Pipework, pipe supporting structures, valves, and instruments are not included. • The goods need to be shipped within three weeks after the completion of production. If there is any delay, the storage fee 0.5% of order value/week will be collected. Installation plan notes (IMPORTANT): • The customer has to arrange capable 8-10 local helpers (workers), working at least 6 days/week, 10 hours/day. • The costs of Flight Ticket, Local Accommodation, Local Travel, Food and Other Local Costs for the installation supervisors shall be covered by the customer. • The customer has to arrange the installation of big equipment such as crane or scaffold for roof erection. • The customer has to arrange one coordinator for site management ( It would be better be able to speak Chinese ). • The customer has to arrange a permanent power supply, electrician and water supply shall be made available to make all required connections at the time of installation. • The concrete foundation should be finished base on drawings requirement before the tank arrived at the project site by the customer. • Installation day will be counted starting from the day of departure, estimated days not include any delays caused by force majeure, such as bad weather, environment or strike etc., If happens, we will send a separate bill after installation is fully completed. • When the installation supervisor arrives at the project site, the goods must already be got out of containers and the foundation is ready for the installation construction. • Installation Supervision charge is collected according to the actual supervising service period, any shortage of payment will be collected, any overpayment will be refunded.

TANK OPTIONAL COLOR

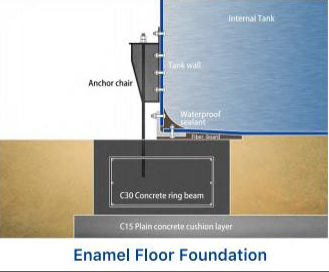

TANK FOUNDATION TYPE

OTHER CONDITIONS • Water filling and emptying as well as the disposal of the water has to be done by the Buyer. Blind flanges have to be provided by the Buyer. • The quantity and quality of the material have to be checked immediately after arrival on site. If there are any faults discovered have to mention within 8 days after getting the material. • The risk of loss to the goods shall pass to Buyer when the goods are duly delivered to the Carrier at Seller�?/span>s factory. The processing of freight claims or loss claims is the responsibility of the Buyer. • The tank floor must not be sloped. No barriers on the foundation. • All the documents provided by us, especially drawings, images, tank design calculations, certificates, data sheets etc., shall not be accessible to third parties if not necessary for fulfilling the contract. • The customer is responsible for working permits, all local installation permits, compliance documentation, site insurances and necessary documentation for the construction works for all our specialist technical advisor/staff. The client is to assist where required with any work visa or entry visa applications for our specialist technical advisor/staff if required, including the cost of such requirements. These potential costs are not included in the price at present. • There is no right of warranty if not follow the maintenance according to our operation manual by the client or a third party.

Civil Engineering List Serial Number | Structure name | Number | Height/ length (m) | Width (m) | Height (m) | structure | Overlook (m3/m2) | 1 | Grating channel | 1 | 6 | 2 | 2 | Steel concrete structure | 24 | 2 | Homogenate pool | 1 | 12 | 6 | 5 | Underground steel reinforced concrete | 360 | 3 | Feed pump well | 1 | 3 | 3 | 5 | Underground steel reinforced concrete | 45 | 4 | CSTR tank foundation | 1 | 24.69 | —� | 0.5 | Steel concrete structure | 239.27 | 5 | Organic fertilizer fermentation tank | 1 | 6.9 |

| 0.5 | Steel concrete structure | 18.69 | 6 | Regulating pool | 1 | 12 | 5 | 5 | Underground steel reinforced concrete | 300 | 7 | Solid liquid separation zone | 1 | 6 | 2 | 0.5 | Steel concrete structure | 6 | 8 | Biogas residue shed | 1 | 10 | 6 | 5 | Steel concrete structure | 60 | 9 | Biogas slurry tank | 1 | 47 | 23 | 5 | earthwork | 4036 | 10 | Biogas boiler room | 1 | 10 | 6 | 3.5 | Steel concrete structure | 60 | 11 | Fan room | 1 | 5 | 6 | 3.5 | Steel concrete structure | 30 | 12 | Generator Room | 1 | 12 | 10 | 5 | Steel concrete structure | 120 | 13 | power distribution room | 1 | 6 | 6 | 3.5 | Steel concrete structure | 36 | 14 | Duty Room | 1 | 4 | 6 | 3.5 | Steel concrete structure | 24 |

|