|

Biogas production program from human waste

Serial Number | Structure name | equipment name | Material | specifications | Unit | Number | Notes | 1 | Screen Canal | Rotary drum screen machine | SS304 | Specification: B=600mm, grid pitch: 5mm, installation Angle 70°, drop height 1m, 1.5kW | pcs | 1 |

| 2 | Sump | Submersible mixer in Sump | SS304 | QJB1.5/6-260/3-960 | sets | 1 | Auxiliary lifting device | 3 | submersible lift pump in Sump | Wetted parts SS304 | Flow: 15 cubic meters/hour, head: 15 meters | pcs | 2 | Supporting lifting device 1 use 1 spare | 4 | Regulating pond | Regulating pond tank body | GFS tank | φ 5.35-4.8(H) | sets | 1 |

| 5 | Regulating pond submersible mixer | SS304 | QJB1.5/6-260/3-960 | sets | 1 |

| 6 | Regulating pond lift pump |

| Sewage pipe pump, 25m3/h�?5m | pcs | 2 | 1 use 1 spare | 7 | Primary Sedimentation tank | Primary Sedimentation tank body | GFS tank | Φ 3.82-4.2(H) | sets | 1 |

| 8 | Coagulation and flocculation dosing box | Carbon steel with anti corrosion treatment |

| sets | 1 |

| 9 | Mixer in Coagulation tank 1 | Shaft and Paddle in SS304 | 1.5kW | sets | 1 |

| 10 | Mixer in Flocculation tank 1 | Shaft and Paddle in SS304 | 1.5kW | sets | 1 |

| 11 | Center pipe of Primary sedimentation tank | Carbon steel with anti corrosion treatment |

| sets | 1 |

| 12 | Primary sedimentation tank overflow weir | PP+SS304 | 12m | sets | 1 |

| 13 | Primary sedimentation tank sludge pump |

| Sewage pipe pump, 15m3/h�?5m | pcs | 2 | 1 use 1 spare |

Lead time: Approx. 50-90days from receipt of advanced payment and tank drawings confirmation, batches shipment will be considered. Warranty: Under proper design and use, 3 years free quality guarantee after delivery; after 3 years, will provide quality guarantee with charge. The warranty of equipment is according to the supplier

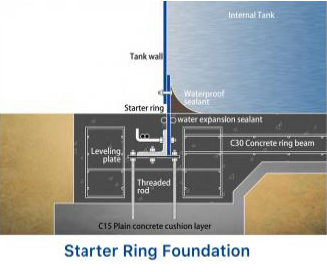

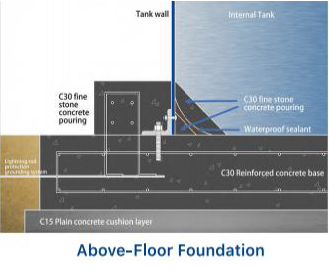

TANK KIT AND ACCESSORIES • Glass-Fused-to-Steel sheets • Self-locking bolt (HDG) with PP cap, nut, washer, including 3% backup • Silicon sealant, waterproof sealant • HDG top&bottom angles, HDG wind wind girder (stiffener) • Access vertical; ladder with safety cage and platform 1M x 1M (HDG) • 1*DN600 manway, nozzles designed according to file DESIGN CRITERIA Design Code: AWWA D103-09, OHSA, EN/ISO 28765, EURCODE Application: Biogas plant turnkey project Wind load: 100mph Snow load: 15psf Seismic Zone: Zone 4 acc. AWWA Fluid Temperature: -5〜75 Degree C. PH Range: 3〜11 Specific Gravity: 1 Operation temperature: Ambient Pressure: 3500PA (enamel roof), 500~1000PA (membrane roof) Vacuum: -500PA( enamel roof), -200PA (membrane roof) Edge Protection: Enameled edge Panel Bolts: HDG bolt with PP capped Foundation Type: Embedded TANK SPECIFICATION Standard Color: Dark Blue (RAL 5004), Dark Green (R6006L) Coating Thickness: 230 mircon 〜480 micron Steel Size: 2400 x 1200mm Steel thickness: 3 - 12mm Adhesion: 3,450 N/cm2 Hardness: 6.0 Mohs Service Life: 30 Years Holiday test:_1500 V

QUOTATION CONDITIONS • Quotation includes above-mentioned accessories. for any further special accessories/design demands, quotation needs to be revised accordingly. • Concrete foundation, waterproof construction, Pipework, pipe supporting structures, valves, and instruments are not included. • The goods need to be shipped within three weeks after the completion of production. If there is any delay, the storage fee 0.5% of order value/week will be collected. Installation plan notes (IMPORTANT): • The customer has to arrange capable 8-10 local helpers (workers), working at least 6 days/week, 10 hours/day. • The costs of Flight Ticket, Local Accommodation, Local Travel, Food and Other Local Costs for the installation supervisors shall be covered by the customer. • The customer has to arrange the installation of big equipment such as crane or scaffold for roof erection. • The customer has to arrange one coordinator for site management ( It would be better be able to speak Chinese ). • The customer has to arrange a permanent power supply, electrician and water supply shall be made available to make all required connections at the time of installation. • The concrete foundation should be finished base on drawings requirement before the tank arrived at the project site by the customer. • Installation day will be counted starting from the day of departure, estimated days not include any delays caused by force majeure, such as bad weather, environment or strike etc, If happens, we will send a separate bill after installation is fully completed. • When the installation supervisor arrives at the project site, the goods must already be got out of containers and the foundation is ready for the installation construction. • Installation Supervision charge is collected according to the actual supervising service period, any shortage of payment will be collected, any overpayment will be refunded.

TANK OPTIONAL COLOR

TANK FOUNDATION TYPE

OTHER CONDITIONS Water filling and emptying as well as the disposal of the water has to be done by the Buyer. Blind flanges have to be provided by the Buyer. The quantity and quality of the material have to be checked immediately after arrival on site. If there are any faults discovered have to mention within 8 days after getting the material. The risk of loss to the goods shall pass to Buyer when the goods are duly delivered to the Carrier at Seller�?/span>s factory. The processing of freight claims or loss claims is the responsibility of the Buyer. The tank floor must not be sloped. No barriers on the foundation. All the documents provided by us, especially drawings, images, tank design calculations, certificates, data sheets etc., shall not be accessible to third parties if not necessary for fulfilling the contract. The customer is responsible for working permits, all local installation permits, compliance documentation, site insurances and necessary documentation for the construction works for all our specialist technical advisor/staff. The client is to assist where required with any work visa or entry visa applications for our specialist technical advisor/staff if required, including the cost of such requirements. These potential costs are not included in the price at present. There is no right of warranty if not follow the maintenance according to our operation manual by the client or a third party.

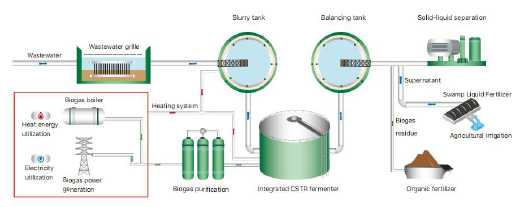

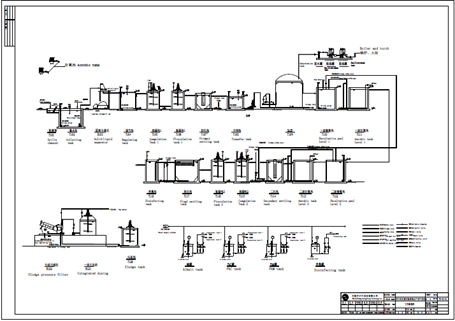

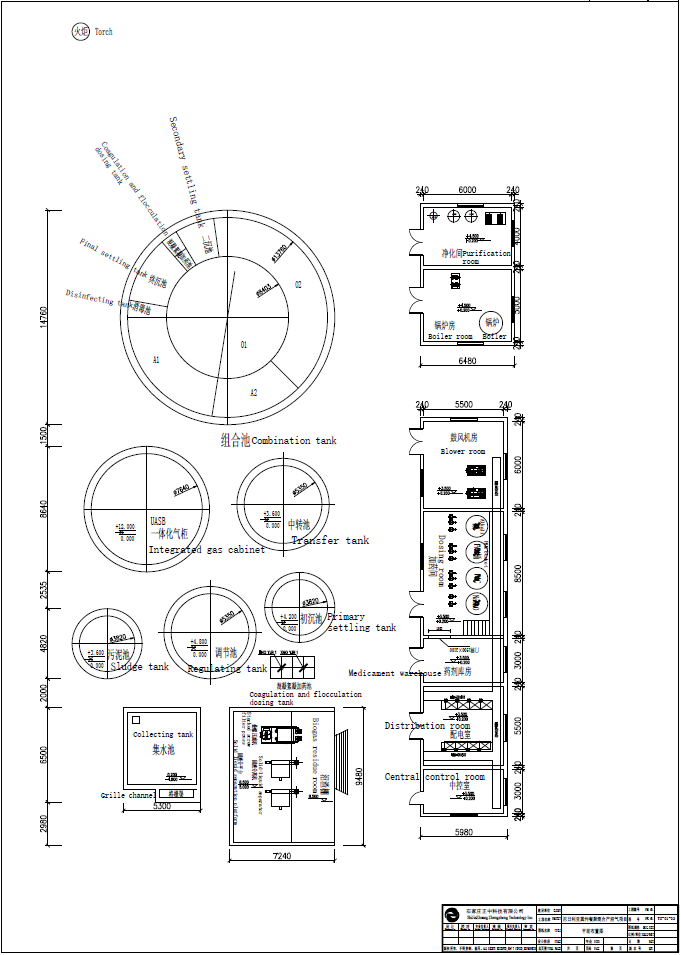

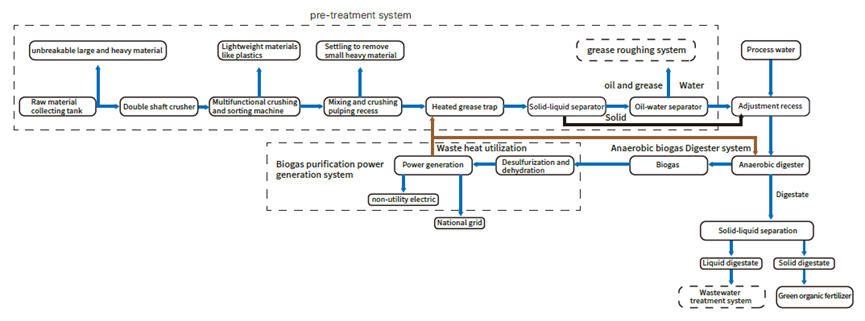

Feces and food waste mixed biogas production project I Project Overview 1.1 Project Overview This solution is used in feces and kitchen waste mixed biogas production project. The source of wastewater is the feces and kitchen waste of 3,000-6,000 people in the local army. 1.2 Project general information Project name: Proposal for biogas production project from manure Project scale: 100 tons/day 1.3 Design Principles 1) Strictly implement various national environmental protection regulations to ensure that the treated sewage water quality meets the discharge standards required by the national and bidding unit documents; 2) The sewage treatment process is selected based on the principles of advanced and reasonable technology, stable and reliable process operation, and simple operation and management, so as to organically combine flexibility, advancement and reliability; 3) Use mature advanced technology and fully consider the impact of the impact load of sewage quality and quantity on the system to ensure better stability of the treatment system; 4) The main equipment adopts mature and advanced technology and equipment to minimize project investment and operating costs; 5) In the layout and engineering design, the terrain and surrounding environment are combined, and the layout strives to be compact, simple, beautiful, fully functional, with reasonable and smooth process flow, saving land space and ensuring green area; 6) The design of the sewage treatment system should consider stable operation and simple and convenient maintenance and management as much as possible; 7) Strictly implement relevant national design codes and standards, especially mandatory safety regulations. II Design condition 2.1 Treated capacity According to the customer data, considering the maximum number of 6000 people, the estimated water separation per person per day is 14.3kg, and the solid content is about 0.5%; The estimated kitchen waste per person per day is 0.85kg, and the solid content is about 20%. After the merger, the estimated daily wastewater volume is about 90.9T. Considering the influence of fluctuations, this scheme is designed according to the sewage volume of 100T/d, and the flow rate is 5m3/h when considering 20 hours per day. 2.2 Project Scope The design and construction scope of this project is: equipment design and procurement within the starting and ending range from the water intake of the grid canal to the water discharge of the disinfection tank.

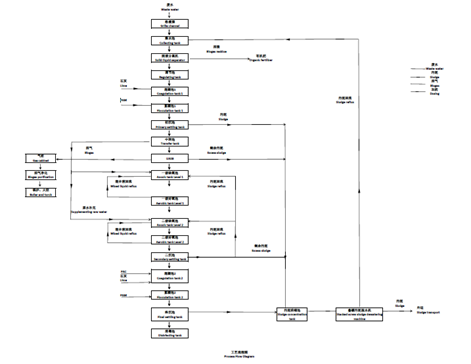

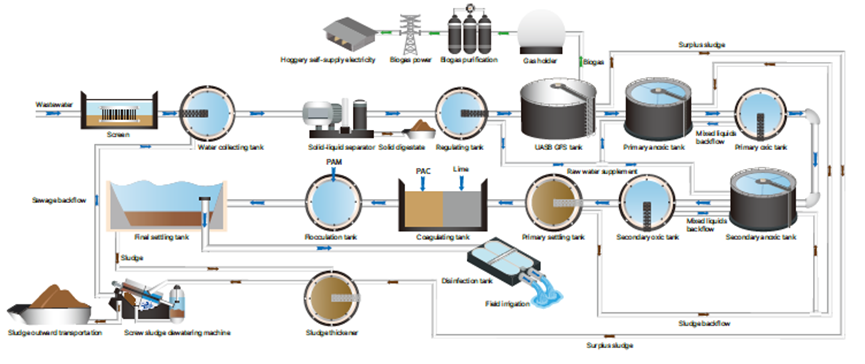

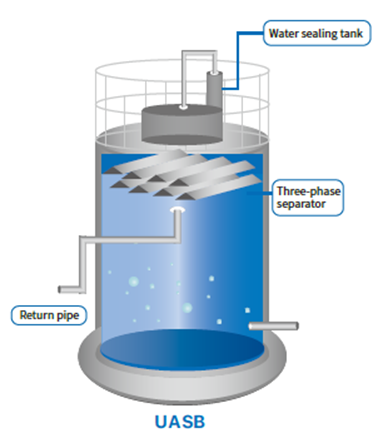

III Process design 3.1 Sewage treatment technology After understanding the source and characteristics of the sewage in this project, and referring to the experience of other related sewage treatment projects and industry-leading treatment processes done by our company, the treatment process of "UASB anaerobic process +AOAO" is selected in this scheme based on the principle of stable and reliable operation, saving investment, reducing operating costs, facilitating daily operation and management, and ensuring treatment effect. To ensure that the methane can be produced at the same time the water standard. 3.3 Process flow chart

3.4 Process specification Preprocessing part The waste water first passes through the grille channel, and the mechanical grille will separate the large debris in the waste water, including waste paper, cigarette butts, and leftover plastics; The initially separated waste water enters the sump, and is evenly mixed with the pre-treated, oiled and separated food and kitchen waste through the mixer, and then sent to the solid-liquid separation workshop; SS in sewage is removed by solid-liquid separator to reduce the load of subsequent treatment and the risk of fouling in pump. The wastewater filtered by the solid-liquid separator contains a large number of fine particles that cannot be removed by the solid-liquid separator. After adjusting the stable water volume of the tank, it is stably transported to the primary sedimentation tank through the pump. Coagulant and flocculant must be added to the wastewater to form large particles of alum into small SS floc, so as to achieve the purpose of gravity precipitation, which not only reduces the negative coagulation load of the subsequent biochemical system, but also the first step of phosphorus removal. The effluent from the primary sedimentation tank is pumped to the UASB tank by lifting pump after mixing in the transfer tank to fully homogenize the water quality and quantity. Anaerobic portion Upflow anaerobic sludge bed reactor (UASB) is a kind of reactor with simple structure, which is suitable for low suspended solid organic material. The raw materials enter the digester from the bottom, and contact with the activated sludge in the digester, so that the raw materials can be quickly digested. Undigested organic solid particles and biogas fermentation microorganisms are retained in the digester by natural sedimentation, the supernatant overflows from the upper part of the digester, and the gas is separated by the three-phase separator and enters the gas reservoir through the collecting pipe. This results in a much higher solid retention period (SRT) and microbial retention period (MRT) than the hydraulic retention period, thus improving the decomposition rate of solid organic matter and the efficiency of the digester. Because UASB has simple structure, high volume load rate, short hydraulic residence time of wastewater in the reactor, no stirring is required, and can adapt to relatively large load impact, temperature and pH changes, it is suitable for the treatment of high-concentration organic wastewater, and has a high removal rate of organic pollutants, among which the chemical oxygen consumption (CODCr) removal rate is 80-90%. The removal rate of five-day biochemical oxygen demand (BOD5) is 70-80%, and the removal rate of suspended solids (SS) is 30-50%. Post-processing section Due to the high COD and ammonia nitrogen of fecal wastewater, it is difficult to reach the standard after a process of nitrification and denitrification. Moreover, the biodegradable substances in the wastewater after UASB reactor are greatly removed, while most of the remaining substances are difficult to degrade and are difficult to be oxidized by activated sludge. Therefore, this scheme adopts A two-stage A/O process. The wastewater from the UASB reactor enters the two-stage A/O biochemical treatment system, and passes through the first-stage anoxic tank, first-stage aerobic tank, second-stage anoxic tank, second-stage aerobic tank, and sedimentation tank in turn. The COD and BOD in the wastewater treated by UASB reactor have been removed in a large proportion, and the remaining pollutants belong to the long chain organic matter which is difficult to treat. Therefore, the wastewater is first introduced into the anoxic pool, and the polymer long chain organic matter is broken by facultative bacteria to decompose it into small molecules that are easy to biodegrade. After anoxia, the waste water flows into the aerobic tank, and the metabolism of the acclimated aerobic bacteria decomposes the easily degradable organic matter in the waste water into carbon dioxide and water. Anoxic pond Biological nitrogen removal is mainly carried out in anoxic pond. Biological nitrogen removal includes two processes: nitrification and denitrification. The process of nitrification is the conversion of ammonia nitrogen into nitric nitrogen under the action of nitrifying bacteria. Nitrobacteria are chemoautotrophs, which do not require organic nutrients for their physiological activities. They obtain carbon sources from carbon dioxide and energy from the oxidation of inorganic substances. The denitrification process is to reduce nitric nitrogen and nitrite nitrogen to nitrogen under the action of denitrifying bacteria. Denitrifying bacteria are heterotrophic facultative anaerobic bacteria, it can only use nitric acid and nitrite ion oxygen in the absence of molecular oxygen to breathe, so that nitric acid reduction. The main function of the anoxic pool is to carry out the denitrification process. At the same time, the circulating mixture in the aerobic pool returns to the anoxic pool, and the denitrifying bacteria in the reflux sludge use the organic matter in the sewage as the carbon source to reduce a large amount of nitric nitrogen in the reflux mixture to nitrogen, so as to achieve the purpose of nitrogen removal. The aerobic tank mixture enters the aerobic reaction zone from the anoxic reaction zone. This reaction zone unit is multifunctional. BOD5 removal, nitration and phosphorus absorption reactions are all carried out in this reactor. All three reactions are important, the mixture contains NO3-N, the sludge contains excess phosphorus, and the BOD5 in the sewage is removed. The aerobic tank returns the mixture of 200% of the original sewage to the anoxic reaction tank. Using anoxic + aerobic process, the main function is to remove the residual organic matter in the sewage through the aerobic biochemical process, further degrade COD, and convert ammonia nitrogen into nitrate through the nitrification process. Through the aerobic P absorption and anaerobic P release effect of phosphorus accumulating bacteria (Microgram-negative Brevicella), organic matter in sewage is oxidized and decomposed, and phosphorus in sewage is stored in the bacteria in the form of polyphosphate to form high-phosphorus sludge, which is discharged through the residual sludge and has a good phosphorus removal effect. Before the wastewater from the aerobic tank enters the reaction tank, the sedimentation tank is added to remove the aerobic bacteria formed by aerobic bacteria and the dead and shed SS, which can optimize the treatment environment and treatment effect of the coagulation/flocculation system and reduce the dosage of chemicals. Sludge from sedimentation tank is pumped into anoxic tank through sludge pump to increase sludge reflux of the whole system, and the remaining sludge is discharged into sludge tank for sludge treatment. The effluent water after biochemical treatment contains a large number of dead and shed bacteria, so coagulants and flocculants must be added to the wastewater to form large particles of alum flowers, so as to achieve the purpose of gravity precipitation. After the final sedimentation tank is discharged, the sewage still contains many bacteria, viruses and microorganisms. After the biochemical treatment in the first stage, the microbial indicators may not meet the discharge requirements. Therefore, NaClO must be added to the terminal disinfection tank for disinfection, to remove the bacteria such as coliform in the water, and further oxidize the organic pollutants in the wastewater, so as to better guarantee the discharge of the sewage up to the standard. Finally, the sewage is discharged according to the standard. Other parts Biogas is collected through water-sealed tanks, desulfurization tanks and biogas tanks, and then incinerated by boilers. Hot water can be used for heating in the factory area, and excess biogas is burned through the torch. The residual sludge produced by the sewage station is dehydrated by the screw sludge dewatering machine, and the sludge cake can be transported directly after the moisture content reaches 80%. 3.5 Biogas calculation Based on the projected water volume, it can be calculated that the daily biogas production is about 540 cubic meters. It is generally believed that a household (3-5 people) uses about 1 cubic meter of biogas per day, and 540 cubic meters of biogas can be used by 540 families for daily cooking. 3.6 Process advantage �?/span> The system is stable and the effluent water quality is stable, which has obvious advantages compared with other processes and is suitable for this project. �?/span> The equipment can be assembled tank structure, with short construction period, low investment, saving land, beautiful appearance and so on. �?/span> The input cost is low, the operation and management are simple, and the economic and environmental benefits are achieved. �?/span> The late maintenance workload is low, and the requirements for operation operators are relatively low. IV Utility design The design of public facilities in this project first follows the relevant norms, regulations and regulations of China's construction engineering, and tries to be practical and beautiful under the premise of meeting the use function. In the planning, the greening method combining point, line and surface is adopted, and the engineering layout is carried out from the plane and three-dimensional two directions. Under the premise of meeting the technological requirements, the topographic and geological conditions are used as far as possible to reduce the amount of earthmoving works, so that the building foundation design can achieve economic and reasonable. The treatment of the facade of the building and the form of the building structure should be integrated and coordinated with the surrounding buildings, taking into account local experience and customary practices. The structural system and structural scheme of the building are analyzed and compared, and the reasonable scheme which is convenient for construction and production is adopted, so that each unit within the scope of the project can not only be an independent body, have a unique style, but also complement the surrounding environment. 4.1 Electrical and instrumentation design 4.1.1 Design scope The scope of this design includes: power system and automatic control system. 4.1.2 Power supply system This project adopts a stable power supply system, which is led from the nearby power supply point buried or overhead laying to the electric control cabinet in the central control room. 4.1.3 Cable laying All the cables leading from the electric control cabinet in the central control room are laid along the bridge, and the lines leading from the bridge to the electrical equipment are VV-1KV power cables, and the PVC pipes are laid open or dark along the wall (ground) or the pool wall. Metal hoses are used to connect the protection pipe to the terminal box of the equipment. The lighting line is covered along the track plate with BV-500V wire through PVC pipe. 4.2 Automatic control system design The automatic control adopts the distributed field bus control system. The test control system is composed of programmable logic controller (PLC) and automatic instrument. 4.3 Ventilation design In order to improve the operating environment, consider fully ventilating the site. Ventilation adopts the combination of mechanical ventilation and natural ventilation. A number of axial flow exhaust fans are set up on the external walls of each institute to exhaust the odorous indoor air to the outside. V The main structure 5.1 Main building specifications and dimensions Table 5-1 Specifications and dimensions of major buildings

5. 2 Major buildings and their equipment 5. 2.1 List of major equipment Table 5-2 lists the main devices

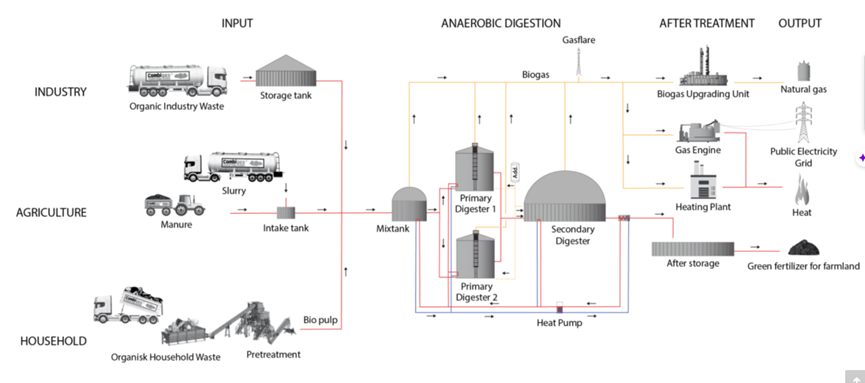

Wastewater Project Wastewater Treatment Advanced Water & Wastewater Treatment Solutions Experts of High Concentration Organic. Turnkey Project Breeding Wastewater Treatment Turnkey Project Natural Gas and Biogas Turnkey Project Industrial Wastewater Treatment Turnkey Project Municipal Sewage Treatment Turnkey Project Anaerobic Processes Package Anaerobic Digestion Process of Landfill Leachate Anaerobic Digestion Process of Biogas Project Anaerobic Digestion Process of Kitchen Waste Anaerobic Digestion Process of industrial Wastewater Biogas Turnkey Project We have developed a set of core patented technologies to comprehensively collect, recycle and scientifically treat all kinds of organic wastes generated in daily life, industry, agriculture and has developed a set of core patented technologies to comprehensively collect, recycle husbandry. The use of mixed raw material digestion technology that does not require classification of pig farm raw materials and maintenance-free super large anaerobic digesters with residual heat insulation of biogas power generation can effectively improve gas production rate and investment utilization rate, Dairy Farm and realize a sustainable and profitable commercial operation mode in biogas projects.

Breeding Wastewater Treatment Turnkey Project The biochemical treatment technology (UASB+ AA/O system + Phosphorus Removal + final settling) is taken as the core process of breeding wastewater treatment turnkey project to ensure maintaining standard of COD, ammonia nitrogen and total phosphorus. Processing harmless and resource treatment to wastewater treatment animal manure of breeding farm, we mix the special fermentation bacteria and carry out EATAD for the animal manure by using environmental biotechnology, so as to achieve rapiddecom position and plants for your industry deodorization, and biologically transform it into high-quality compost.

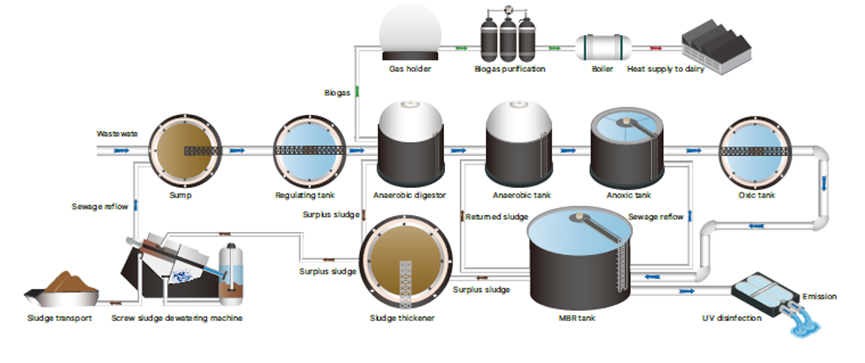

Industrial Wastewater Treatment Turnkey Project Dairy sewage mainly contains a large amount of soluble organics, including sugar, starch, protein, fatty acid. The dairy wastewater is with good biodegradability, and does not contain toxic and harmful substances and large suspended substances(SS).It is milky white and belongs to medium high concentration sewage. From the pretreatment of raw materials, hydrolysis and acidification, anaerobic treatment unit, and biochemical treatment section and so on, the dairy industry wastewater treatment tanks which assembled on site, using the GFS tanks produced by our company. It has the advantages such as low cost, simple construction in short period, minimum maintenance, glossy appearance and so on.

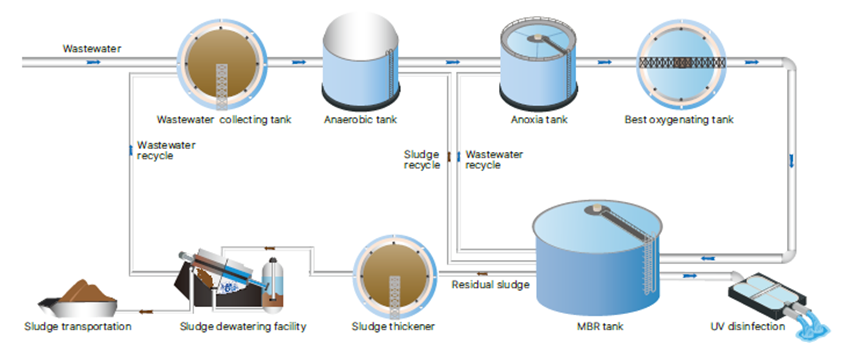

Municipal Sewage Treatment Turnkey Project According to the urban sewage collection method and the characteristics of water quality and our Glass-Fused-to-Steel tank, that launched the treatment equipment which is appropriate for urban and rural integration processing mode, relative concentration processing mode, separate dispersion processing mode and different water volume treatment. We adopt modular production and on-site assembling mode for the engineering equipment, which is with the advantages of low cost, simple and fast construction, minimum maintenance, glossy appearance, etc.

The Core Process In the landfill leachate anaerobic process, the UASB process (Upflow Anaerobic Sludge Bed) or the EGSB process (Anaerobic Expanded Granular Sludge Bed) is applied. These two kinds of reactors have different volumes and rising speeds of water flow, and the working principle and composition structure are without big differences. Both sludge bed have circulation system, heat preservation and heating system, ladder, platform, etc.

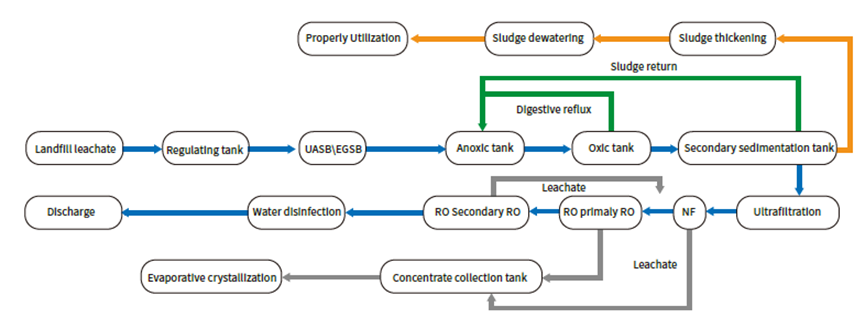

Anaerobic Digestion Process of Landfill Leachate In view of the various problems in the current landfill leachate treatment, we adopt the optimal technical solution to achieve the reduction and harmless treatment of landfill leachate by: Pretreatment + Biochemical method + Membrane separation method. The technical solution is based on the premise of stable and continuous discharge that meets the standard, and comprehensively considers the quality and quantity of landfill leachate as well as the economy, rationality and operability of the treatment process. It can deeply remove organic pollutants that are difficult to degrade. In order to improve the effluent standard of sewage treatment and prevent environmental pollution.

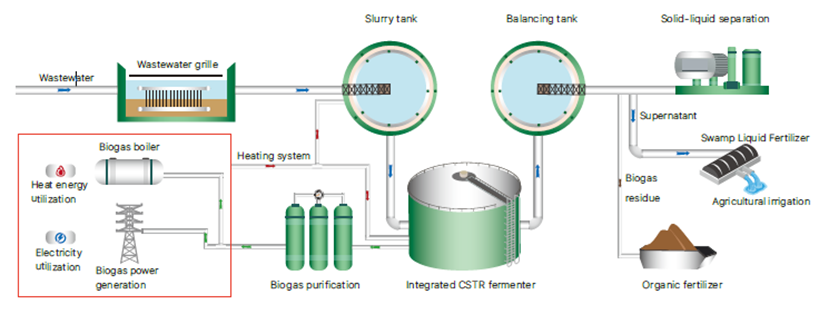

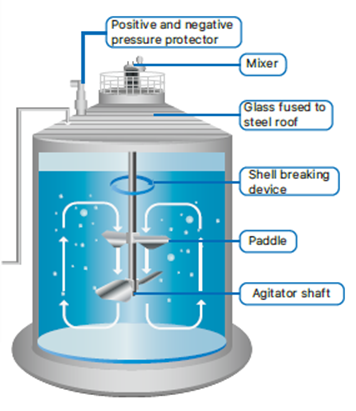

Process Technology Advantage �?span style="font:9px 'Times New Roman'"> Remarkable treatment effect The technology is mature. It can not only remove organic matter and suspended solids in landfill leachate, but also effectively remove ammonia nitrogen and total nitrogen, reduce the number of pollutants and the degree of harm, and ensure that the effluent discharge meets the standard. It is suitable for advanced treatment of landfill leachate. �?span style="font:9px 'Times New Roman'"> Low operation cost In the landfill leachate treatment project, we use the GFS tank independently developed and produced by ourselves as a modular anaerobic treatment unit to replace the structures of the traditional sewage treatment station, realize modular design and construction, and reduce the area of the sewage plant. So that it can reduce the operation costs. �?span style="font:9px 'Times New Roman'"> Little secondary pollution Comprehensive and effective solutions, equipment and technologies will be supplied. The sludge generated in the entire process is collected, concentrated, centrifuged and dehydrated, and properly disposed of without secondary pollution. Certain measures are taken for the odor emission of facilities and equipment to facilitate the later operation of the project. The Core Process CSTR (Continuous Stirred Tank Reactor) is the core process in the anaerobic process section of kitchen waste. CSTR is an anaerobic treatment technology that completely mixes fermentation raw materials and microorganisms in an airtight tank to produce biogas. The CSTR reactor is equipped with a mechanical mixing system, which within the constant temperature or semi-continuous temperature, the organic wastewater with high suspended solids(SS) and high concentration and anaerobic microorganisms are in a state of relatively complete mixing and digestion, which can effectively degrade the organic matter in the wastewater.

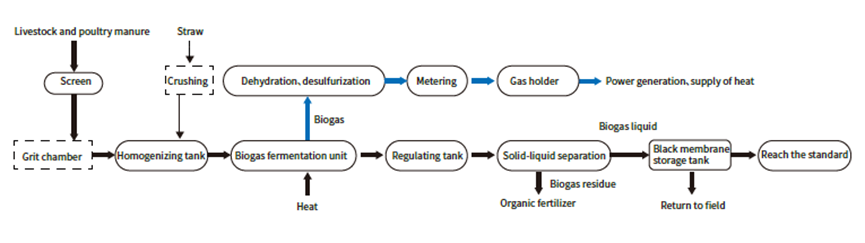

Anaerobic Digestion Process of Biogas Project We have been dedicated in the biomass energy industry for many years, and has achieved fruitful research and development results in biomass energy utilization technology and equipment manufacturing, and has successfully built high-quality biogas projects for many customers at home and abroad. The company transforms organic wastes such as livestock and poultry manure into efficient, clean and convenient biomass energy - biogas through innovative processes, which is of great significance for alleviating the shortage of conventional energy, promoting sustainable social and economic development and improving the ecological environment.

Process Technology Advantages �?span style="font:9px 'Times New Roman'"> More thorough utilization of waste It can carry out comprehensive harmless treatment and resource utilization of livestock and poultry manure, so that various applicable wastes can enter the system for fermentation treatment, with high gas production rate and high overall income. �?span style="font:9px 'Times New Roman'"> Biogas multi-purpose treatment According to the different needs of customers, the biogas generated by the project can be processed for multiple purposes, such as power generation, heating, and biogas purification. �?span style="font:9px 'Times New Roman'"> Stable operation Through process optimization and the use of self-developed complete sets of equipment, the stable operation of the project is ensured, and the utilization of biogas is more valuable. �?span style="font:9px 'Times New Roman'"> Equipment with excellent performance For the treatment of biogas residue and biogas slurry, through a complete treatment system, the treated biogas slurry can meet the discharge standards, and achieve economic and environmental benefits.

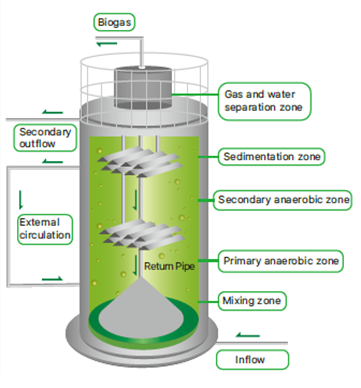

The Core Process In the anaerobic process section of industrial wastewater treatment, IC process (Internal Circulation Anaerobic Bioreactor) is usually adopted. IC reactor is a new generation of high-efficiency anaerobic reactor. It consists of mixing zone, primary anaerobic zone, secondary anaerobic zone, sedimentation zone and gas-liquid separation zone. It is the anaerobic reactor with the highest efficiency in sewage treatment at present. IC process mainly used in the treatment of high-concentration organic wastewater. It enhances the mass transfer process of the internal circulation through high energy consumption. It is widely used in the wastewater treatment of brewery, pharmaceutical, and paper industries, etc. which can effectively reduce operating costs and improve efficiency. This is one of the important methods using to solve the problem of environmental pollution.

Anaerobic Digestion Process of Industrial Wastewater We continue to carry out innovative research and development around sewage treatment technology and equipment. It has mastered a number of core technologies and processes in the field of industrial wastewater treatment, and has the strong advantages on projects, technology and service. The company integrates sewage treatment with enterprise production closely, adopts the optimal technological solutions, improves the effect and operational efficiency of sewage treatment, and comprehensively solves sewage problems for customers in the pharmaceutical, brewery, pulp and paper, soft drink and other industries. Process Technology Advantages Applicable to urban environment, small footprint, without odor, saving investment cost. Vertical tank with complete size options, easy to install. Powerful resistance to impact load, stable in operation, stable effluent quality. Short hydraulic retention time, possess an apparent advantage over UASB. Using a three-phase separator to optimize the retention of microorganisms. Reliable self-adjusting internal circulation system to save energy. The GFS tank is used as the reactor, which is corrosion-resistant and has a service life of over 30 years. Convert organic components into valuable biogas, reduce emission costs as well as lower energy costs.

The Core Process CSTR (Continuous Stirred Tank Reactor) is the core process in the anaerobic process section of kitchen waste. CSTR is an anaerobic treatment technology that completely mixes fermentation raw materials and microorganisms in an airtight tank to produce biogas. The CSTR reactor is equipped with a mechanical mixing system, which within the constant temperature or semi-continuous temperature, the organic wastewater with high suspended solids(SS) and high concentration and anaerobic microorganisms are in a state of relatively complete mixing and digestion, which can effectively degrade the organic matter in the wastewater.

Anaerobic Digestion Process of Kitchen Waste Designing the process of kitchen waste based on the characteristics of different kitchen waste, and the technological process not only meet the needs of customers, but also maximize economic benefits. What�?s more, we also provide the equipment package with the excellent performance in order to operate the project for a long time. Therefore, our process design of the kitchen waste treatment system can not only improve the treatment efficiency of kitchen waste, but also maximize the utilization of resources to reduce environmental pollution and conform to the concept of sustainable development.

Process Technology Advantages �?span style="font:9px 'Times New Roman'"> Professional technical team The professional technical team with rich experience in kitchen waste treatment. The technological process we design are customized according to different project characteristics and client requirements, which can achieve the best conversion and utilization of kitchen waste. �?span style="font:9px 'Times New Roman'"> Environmental benefits The scheme adopted is adapted to the requirements of the local environmental protection department, which aims to reduce the emission of pollutants. �?span style="font:9px 'Times New Roman'"> Maximize economic benefits The premise is to detoxify and reduce the emission of kitchen waste. At the same time, to achieve maximum resource utilization to reduce the actual operating cost of the project and maximize economic benefits. �?span style="font:9px 'Times New Roman'"> Equipment with excellent performance Equipment with excellent performance, in order to ensure the smooth operation of the project after completion, and reduce the maintenance cost greatly in the future.

Equipment Supply Pretreatment Equipment    Sludge Treatment System    Resource Utilization System

Other Equipment

Storage Tank Solutions Glass-Fused-to-Steel tanks Glass-Fused-to-Steel tank, also known as Glass-Lined Steel tank, is integrated porcelain enamel and steel material fused together at 820 ° C-930 ° C high temperature, the molten glass reacts with the steel plate surface to form an inert and inorganic bond, which combines the strength and flexibility of steel and outstanding corrosion resistance of glass, Glass-Fused-to-Steel technology is the premium coating technology in the storage tanks market.

Stainless Steel Tanks Offering stainless steel storage tanks in a bolted tank design. Stainless steel bolted tank is assembled by stainless steel plates, bolts, special sealant, etc. It is an innovation in the installation of stainless steel welded tanks. The tank uses SUS304, SUS316L, and SUS444 stainless steel plates, which meet the OCr18Ni19 sanitary inspection standards and have the characteristics of lightweight, low cost, sanitary and environmental protection.

Galvanized Steel Tanks Galvanized steel tanks are an economical way of storing liquids and are primarily used for the storage of fire water, drinking water, and irrigation water applications. These tanks are designed strictly to comply with AWWA D103-09 standards and galvanized according to GBT13912-2020 standards. Meanwhile, it is fabricated with galvanized steel panels bolted together making them economical, easy to transport to the project site, easy to erect, and have a long-lasting interior and exterior finish.

Fusion Bonded Epoxy Tanks Center Enamel have jointly developed innovative and optimum Fusion Bonded Epoxy coating technology with the world leading producer of paints and coatings. Center Enamel epoxy tanks quickly get the clients�?acceptance after its launch because of its cost-effective performance and advanced electrostatic spraying technology. Our Fusion Bonded Epoxy modular tanks are meet or exceed the requirement of AWWA D103-09 and ISO 9227 / ASTM B117 etc.

Roof Solutions Aluminum Geodesic Dome Roofs Aluminum geodesic dome roofs are a self-supporting cover, which is fabricated from high-strength aluminum alloys. Our aluminum dome roofs are fully compliant with AWWA D108, API 650, ADM2015, ASCE7-10, IBC 2012 standards. The clear-span, all-aluminum, lightweight, corrosion-resistant structure of the aluminum dome roof results in a cost-effective solution that provides superior protection of your stored product. Glass Fused to Steel Roofs air-tightness, glass fused to steel roof is suitable for anaerobic digestion condition. cone shape roof with external/internal beams according to the requirement optimum material same as tank sidewall

Aluminum Alloy Deck Roofs economic option for potable water, wastewater, and fire water storage etc. only protect from raining and wind, without air-tightness.

Single or Double Membrane Roofs suitable for anaerobic digestion condition with biogas collection purpose integrated AD tank with the cover on top of tank, air-tightness

FRP Roofs suitable for no air-tightness required situation such as drinking water, agriculture, fire water, and wastewater storage the shape of FRP roof can be dome or flat

Project Reference-EPC Project Dairy wastewater treatment turnkey project Dairy sewage treatment project built. Mainly treats the wastewater of dairy farms Technology: IC+A2O Treatment capacity : 6,000 Tones waste water per day.

Dairy wastewater treatment turnkey project Dairy Breeding Sewage Treatment Project Technology: IC + A2O Treatment capacity : 8,000 tons wastewater per day

Municipal sewage treatment project Technology: Ultraviolet Disinfection+Two A/O + Sedimentation Treatment capacity: 50,000 Tons/Day)

New Hope 5S swine wastewater Treatment project New Hope 5S hoggery swine wastewater treatment Project was built in Beijing, mainly dealing with pig manure and rinse sewage. The technology is “Pre-process + UASB + Two A/O system+ Coagulating Sedimentation + Oxidation Pond�? treatment capacity is 580m3/ day.

China green group's biological biogas project was built China green group's biological biogas project was built. It mainly treats animal manure and grass straw in the farm, with a biogas output of 30,000 m3/day.

Domestic sewage treatment turnkey project in Ghana Technology: UBF, A2/O Treatment capacity: 1800M3/day

Farming and animal husbandry farms biogas turnkey projects The large-scale biogas project of Agriculture and Animal Husbandry Farm was built, It mainly treats animal manure and flushing sewage in the farm. And the processing capacity is 400m3/day.

Breeding plant wastewater treatment project The breeding sewage treatment project was built. The installation is completed in March 2017. Treatment Process: Pre-process +USR+AOAO+ Advanced treatment Processing treatment capacity: 600m3/ day.

Wastewater treatment project Wastewater Treatment Project was built. Treatment Process: Pre-process +USR+AOAO Processing treatment capacity: Manure cleaning by water submerging 300m3/ day

|