Product Overview

The mechanical diaphragm metering pump is a diaphragm pump that relies on mechanical direct drive for the deflection and deformation of the diaphragm.

Mechanical diaphragm metering pumps are generally suitable for conveying liquids without solid particles with a temperature of -15°C~85°C and a viscosity of 0.3mm²/s~2000mm²/s. The flow rate can be continuously adjusted in the range of 0-100%, and the product has no leakage, simple structure, low maintenance cost, and good cost performance. The products are suitable for environmental protection, water treatment, pharmaceutical, papermaking, new materials and other industries, sexual slurry and hazardous chemicals.

function

1. The flow control mode of the pump has manual control and automatic control. Automatic control can be achieved by frequency conversion, and can also be achieved by adding a digital controller or stroke controller for the metering pump.

2. Parameter range: flow rate is 0.47~6000L/h, maximum working pressure 1.2MPa optional; The flow stability accuracy can be controlled at 1%.

3. Suction capacity: �?m (water column)

4. The product does not have a safety discharge device, and when the system is formed, the outlet pipeline of the pump needs to consider the installation of safety valves to improve the safety of operation.

5. Conveying flammable, explosive, highly corrosive, toxic and other dangerous chemicals, in order to prevent accidents caused by diaphragm rupture, the hydraulic end structure of double diaphragm with diaphragm rupture alarm device can be selected.

Fluid end overflow parts

According to the characteristics of the conveyed agent, the flow parts at the fluid end must meet the requirements for corrosion resistance.

Materials available: PVC, PVDF, PTFE, SS304, SS316L and other alloys (such as: alloy 20, 904L, titanium, Hastelloy, etc.).

Diaphragm material: PTFE or rubber composite PTFE.

Features introduced

1. The use of high-strength PTFE diaphragm, corrosion resistance, long life, suitable for transporting all kinds of corrosive and dangerous liquids.

2. The use of double diaphragm with diaphragm rupture monitoring, for the transportation of various flammable, explosive, highly toxic, radioactive, strong irritating, strong corrosive liquids, can improve the safety of product operation.

3. High-precision one-way check valve structure, with accurate measurement, compact structure, good sealing, long life, strong interchangeability, low cost, easy installation and many other advantages.

4. The motor stands above the gearbox, which effectively avoids the leakage of lubricating oil and improves the reliability of transmission.

5. It can be equipped with a variable frequency motor to receive 4-20mA signal to adjust the flow, and the digital controller or stroke controller of the metering pump designed by Ailipe can be used for external automatic control.

6. The transmission mechanism is lubricated with oil, only need to replace the lubricating oil regularly, and the lubrication system does not need special maintenance.

7. The transmission box is made of high-strength aluminum alloy material, which is light in weight.

8. The fluid end overflow parts are available in PVC/PVDF/PTFE, 304/316 and other materials, and other special materials can also be customized according to the requirements of use, so as to be suitable for conveying various corrosive and non-corrosive liquids.

Product parameters

Model | Rated current (L/H) | Maximum Pressure (Mpa) | Process (mm) | Pump speed (min2) | Diaphragm Specification (mm) | Inlet and outlet connections (mm) | Motor Power (KW) | WEIGHT (KG) |

JXM-A 2.25/1.2 | 2.25 | 1.2 |

| 36 | φ63/36 | DN8 | 220V/380V

0.37KW

1400RPM

3-50HZ IP55/F | 18 |

JXM-A 4.5/1.2 | 4.5 | 1.2 | 72 |

JXM-A 10/1.2 | 10 |

| 144 |

JXM-A 22/1.2 | 22 | 4 | 72 | φ82/45 | DN15 |

JXM-A 44/1.2 | 44 | 144 |

JXM-A 85/1.0 | 85 | 1.0 | 6 | 72 | φ110/70 |

JXM-A 120/0.7 | 120 | 0.7 | 8 | 72 |

JXM-A 170/0.7 | 170 | 6 |

|

JXM-A 240/0.7 | 240 | 8 | 144?

180 | DN25 |

JXM-A 315/0.5 | 315 | 0.5 | φ116/80 | 0.55KW |

JXM-A 400/0.5 | 400 | 10 |

JXM-A 500/0.5 | 500 |

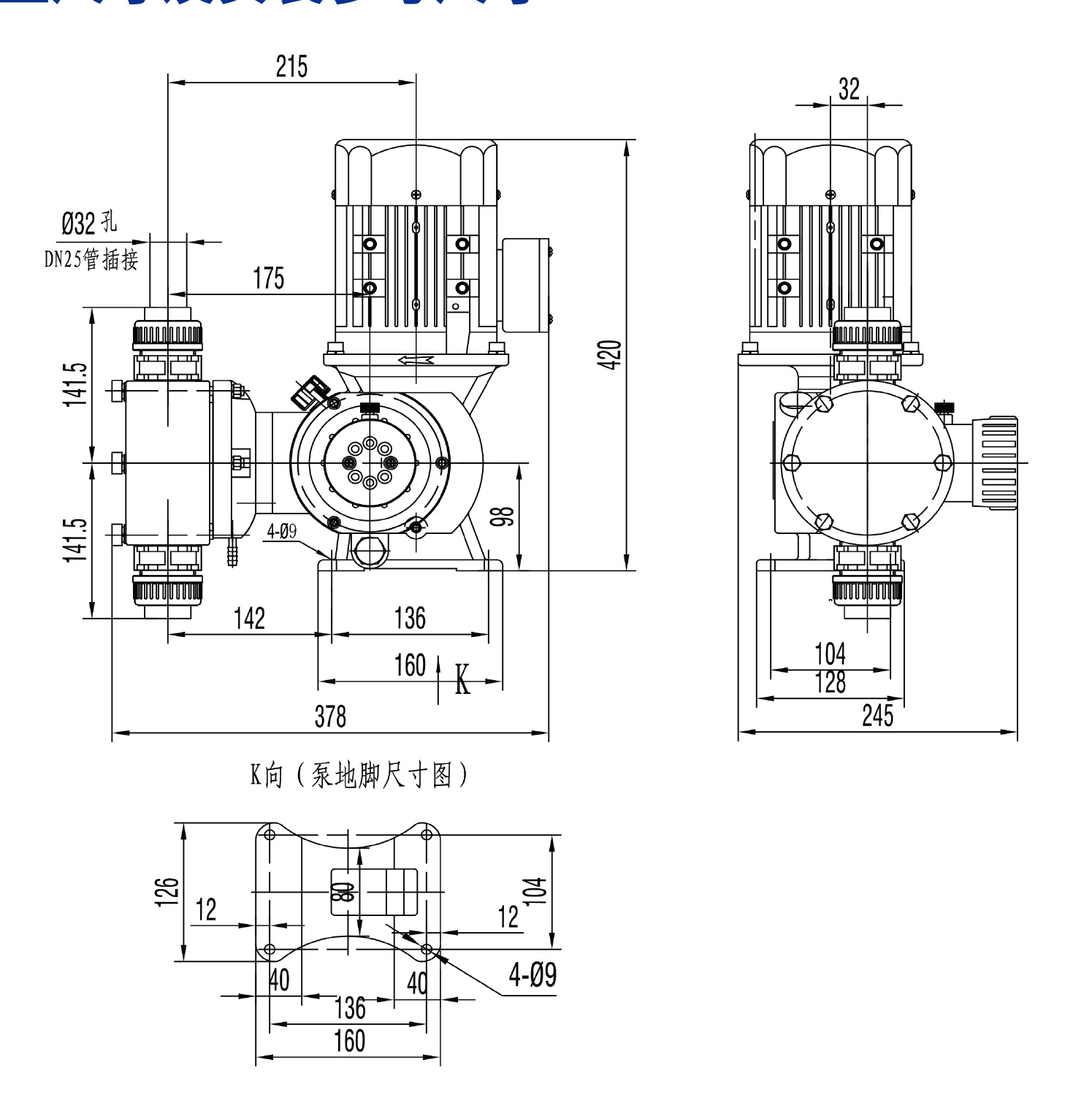

Installation dimensions

Fields of application

It is suitable for environmental protection, water treatment, pharmaceutical, papermaking, new materials and other industries, sexual slurry and hazardous chemicals.